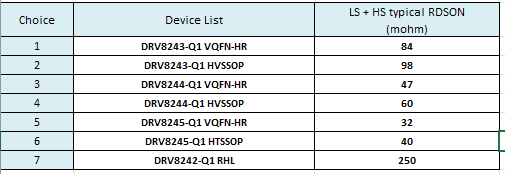

Other Parts Discussed in Thread: STRIKE, DRV8873, DRV8244-Q1, DRV8243-Q1, DRV8245-Q1

Tool/software:

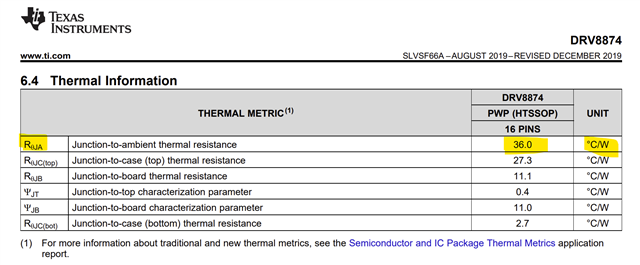

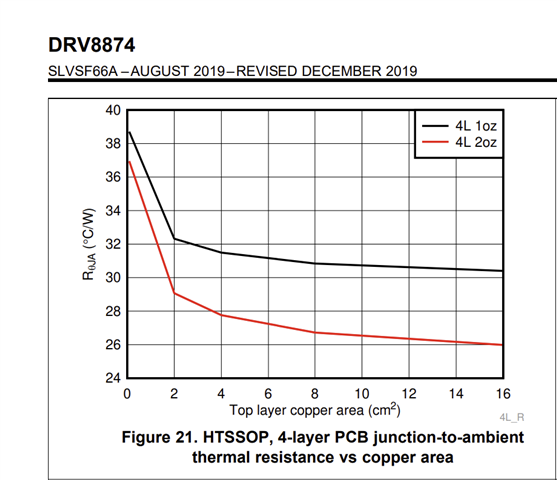

I read the detailed design procedure in datasheet as reference for my design. The example uses 35C/W as RθJA, but does not indicate the copper area applied for this example directly.

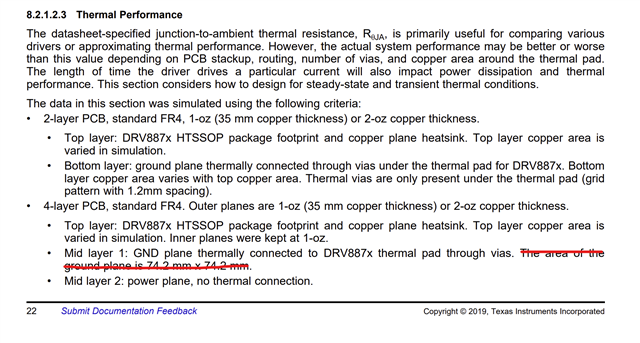

I get the copper area information in page 22:

"

- 4-layer PCB ...

...

Mid layer 1: GND plane thermally connected to DRV887x thermal pad through vias. The area of the

ground plane is 74.2 mm x 74.2 mm.

...

"

It looks like "74.2mm x 74.2mm" to be the copper area for RθJA of 35C/W.

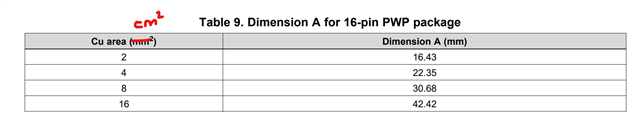

However when I continue the reading , in page 23, Table 9 indicate that for 4 layer, the board dimension is 22.35x22.35. So I am confused with the actual copper area in this example.

May some one can explain to me the actual copper area in this example?