Other Parts Discussed in Thread: DRV8353

Tool/software:

Hi,

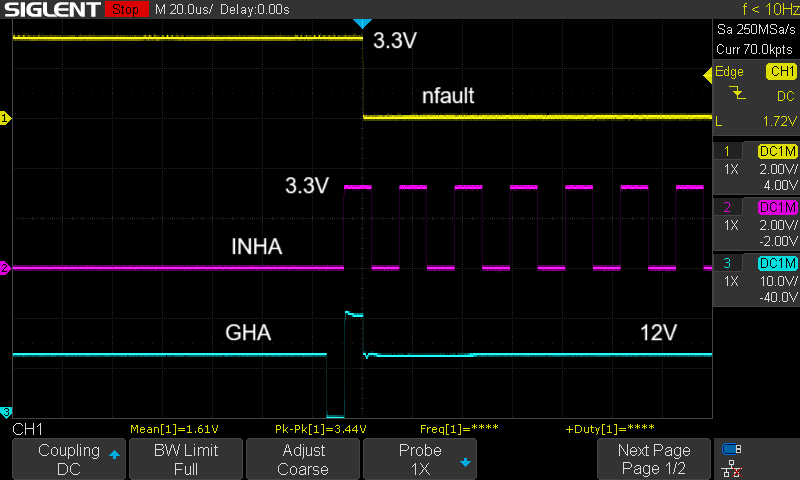

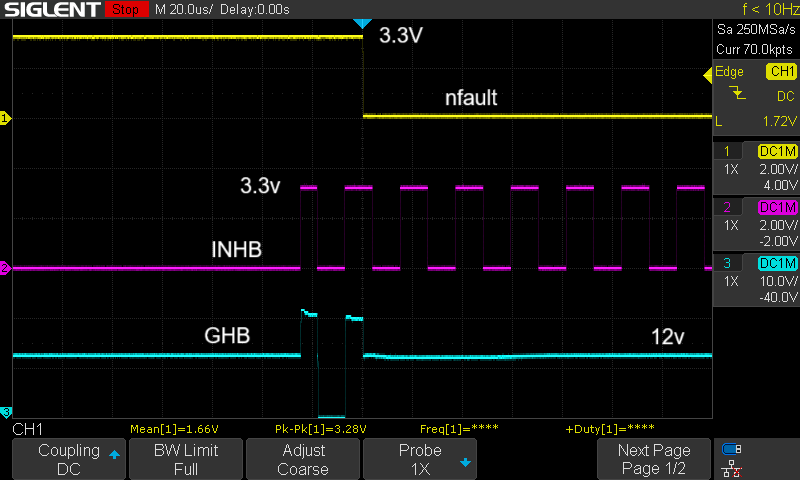

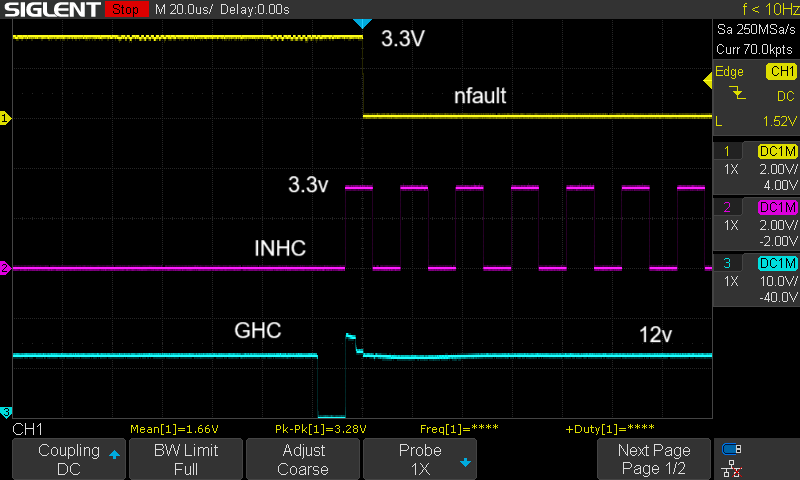

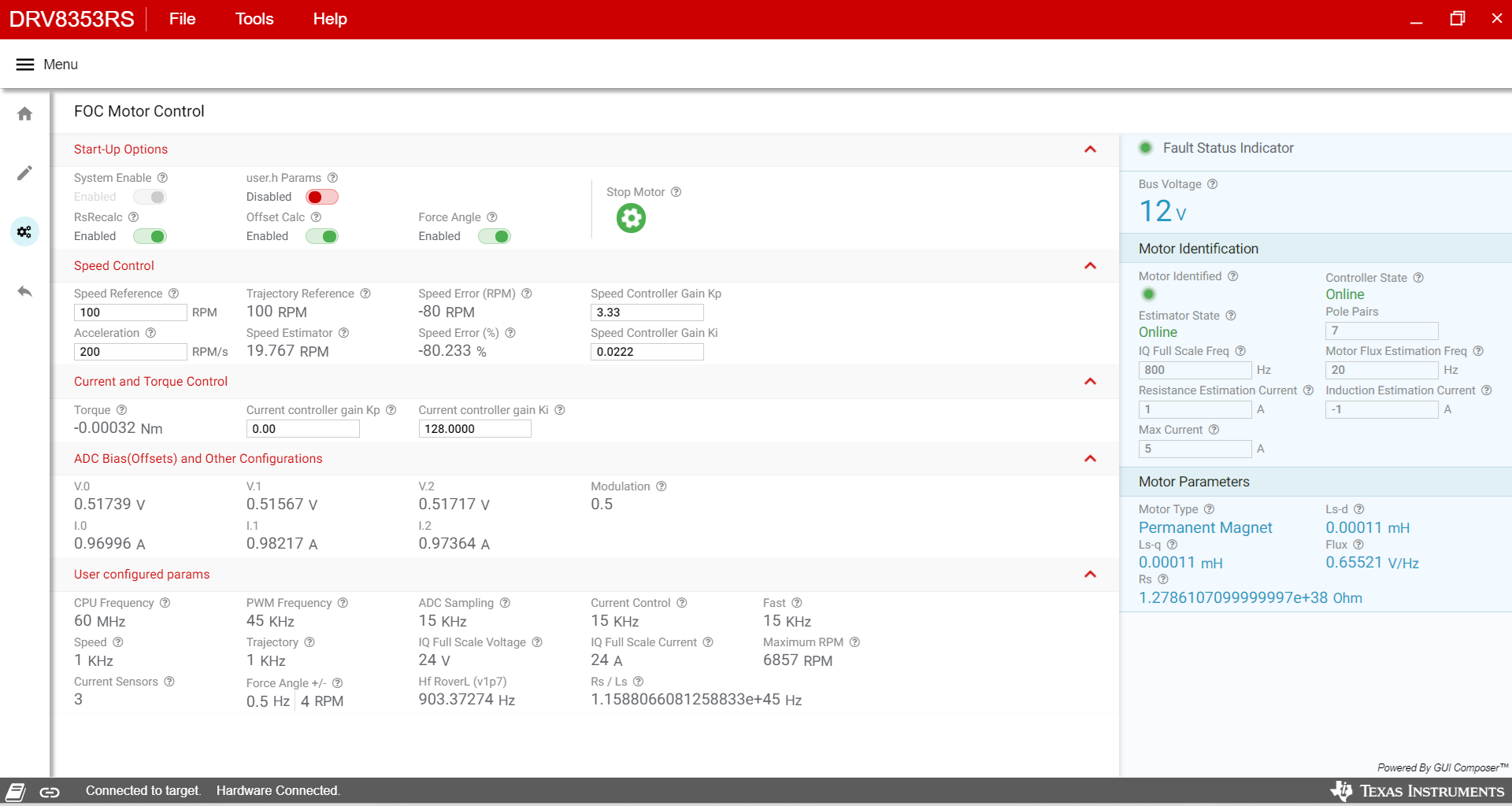

We are facing similar issue where the motor gets identified but not spinning, We tried two different motors, Both did not work.

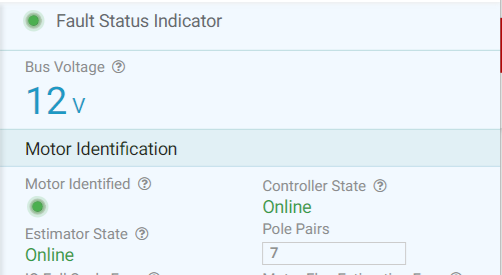

The attached screenshot is of 920KV Brushless DC Motor. Motor has 14 magnets, so we have entered 7 poles.

Software version:

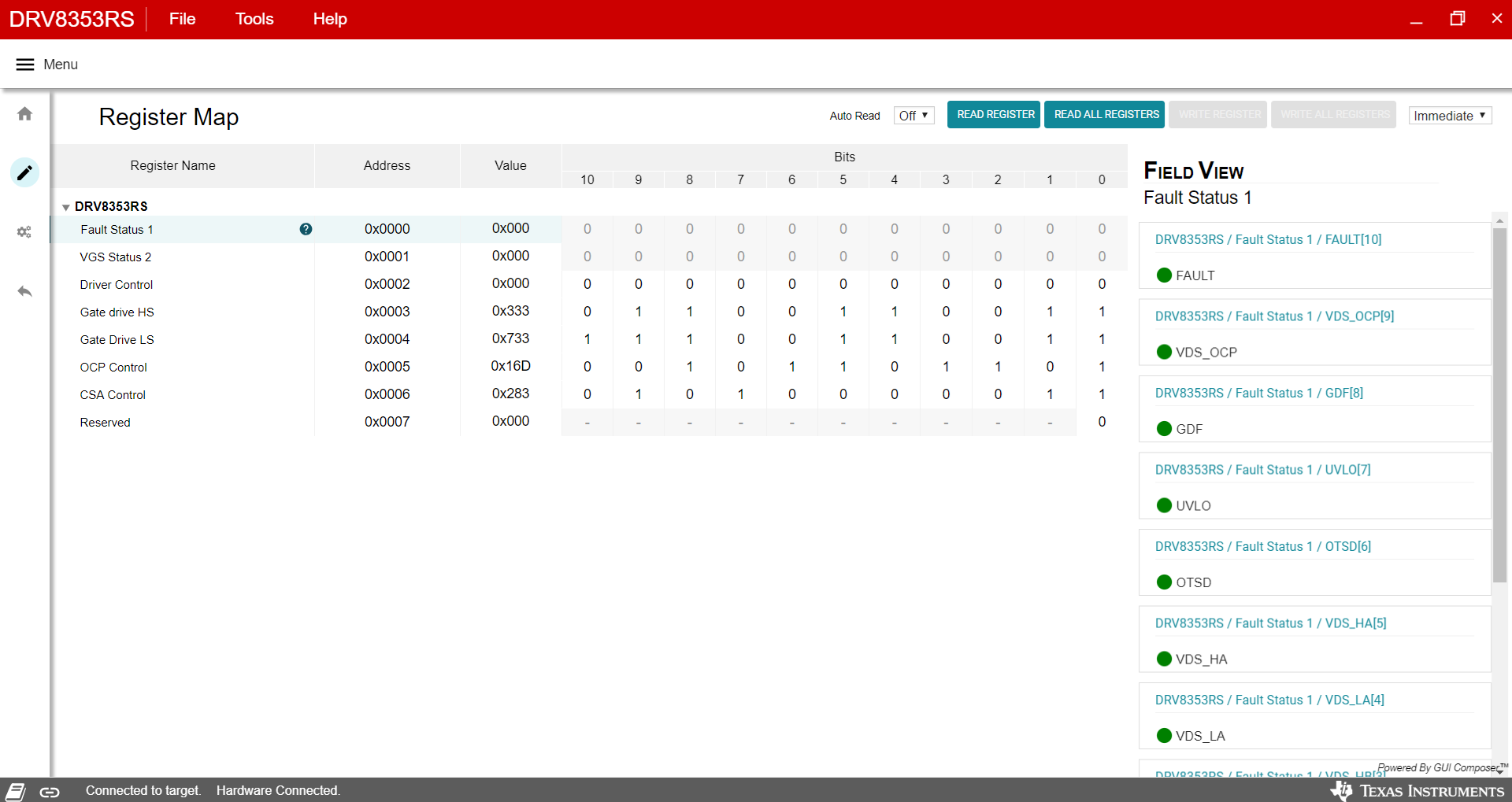

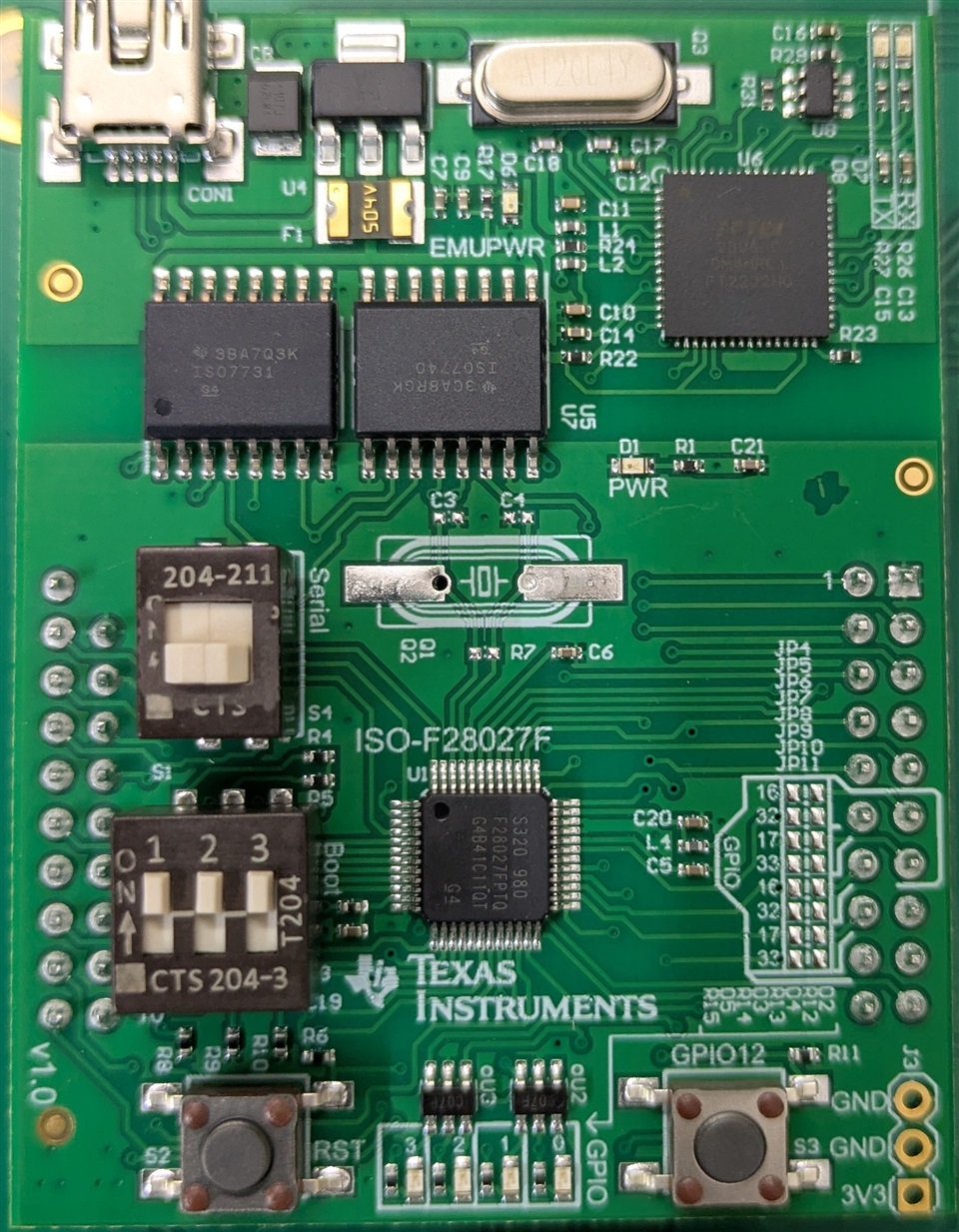

switch settings at default:

To check if EVM is working we disconnected the BLDC and started the process ,observed motor identification was green and motor control /estimator state was also green. Not sure how motor was identified even after BLDC was disconnected.

Please advice how to troubleshoot this problem.