Other Parts Discussed in Thread: DRV8962,

Tool/software:

Hi Team,

Our customer is considering DRV8262 or DRV8962 as alternatives to the DRV8432.

They have asked the following questions.

Could you please confirm whether our interpretations of each question are correct?

1. Regarding the Control Modes of both devices, could you explain the specific differences between PH/EN and Independent 1/2 Bridge?

-

DRV8262: PH/EN

This is one of the H-bridge control methods used in the DRV8262. It is a simple interface that uses two signal lines (PH and EN) to control the motor’s rotation direction and speed. -

DRV8962: Independent 1/2 Bridge

The DRV8962 includes four half-bridge drivers, each of which can be controlled independently. For example, is it possible to configure the device in the following ways?- Drive four solenoids or valves individually

- Drive two brushed DC motors

- Drive one stepper motor

- Drive one BLDC motor (3-phase)

- Drive one or two Peltier elements (TECs)

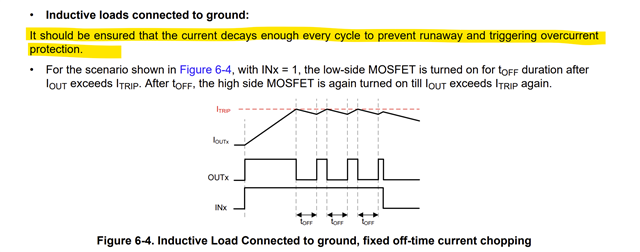

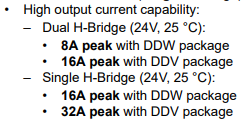

2. Regarding the peak current described on page 1 of the DRV8262 datasheet, what does it mean?

-

Dual H-Bridge Mode

The DRV8262 contains two internal H-bridges, allowing it to drive two brushed DC motors independently. Each motor can receive a peak current of up to 8A/16A. -

Single H-Bridge Mode

This mode connects the two H-bridges in parallel to supply higher current to a single motor. In this configuration, a peak current of up to 16A/32A can be supplied.

Best Regards,