Tool/software:

Hi,

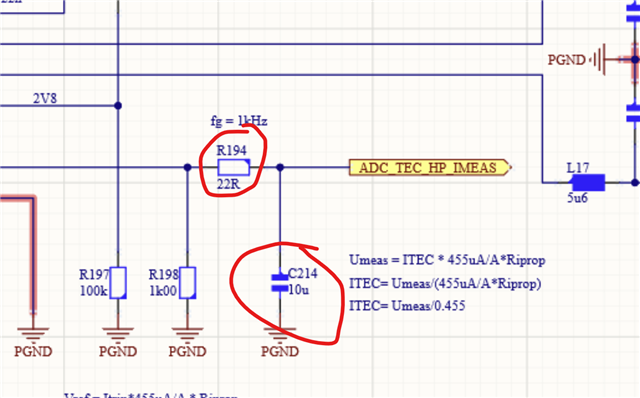

I'm implementing a TEC (Thermoelectric cooler) for a 24V, 3A TEC module. I use the DRV8874 with the following connection:

EN/IN1: PWM input

PH/EN2: Direction input for cooling or heating.

PMODE = low, PH/EN input

IMODE 10kOhm to GND

Iprop = 1k

Vref = 1,4V for ca 3A Current limit.

I connected in series to OUT1 and OUT2 a 5u6 (current rating 6A) choke, the filter caps I connected first to GND from the end of the choke and alos from TEC+ to TEC-

Connection to GND:

I connected also teh caps parallel to the TEC elemen:

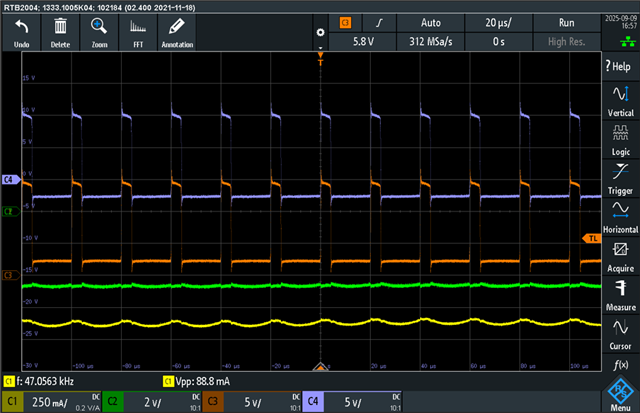

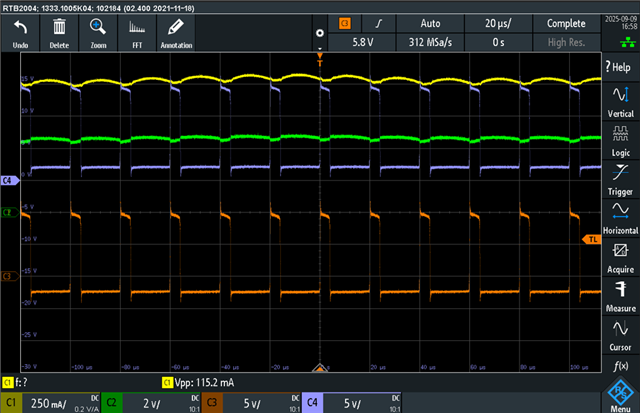

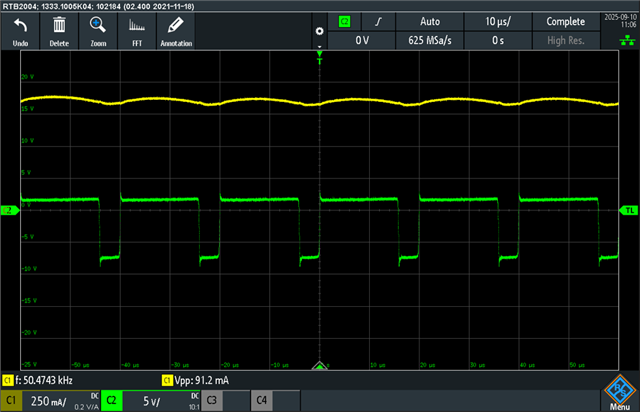

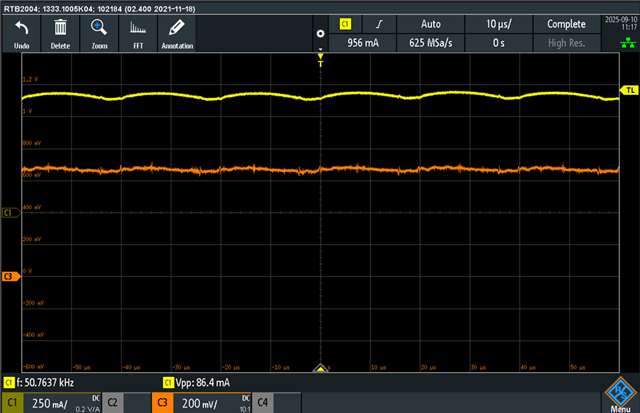

I work with a PWM frequency of 30kHz and a duty cycle of 20%, for testing. teh chokes are getting hot, and the behaviour is not as expected the current is increasing with increasing cuty cycle.

But, with out load (TEC), the current is also flowing somewhere.

Question, is the brake function of the DRV8874 working against me? Currently I have only one PWM output available.

Thanks

Philipp