Other Parts Discussed in Thread: INA241A, DRV8876, DRV8231

Tool/software:

Hi Team,

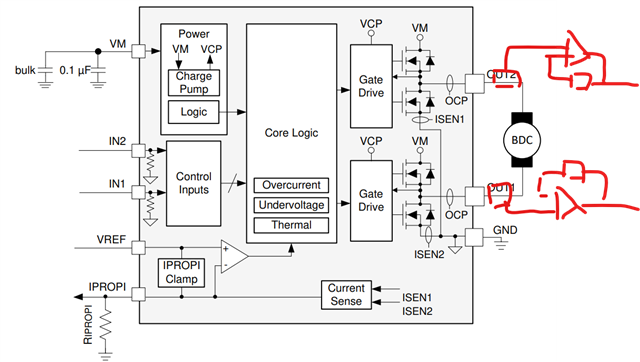

My customer now wants to use DRV8231A as motor driver. And they have accuracy requirement as Iout < 0.05A; error < 5mA. and Iout< 0.15A error as 10mA.

The DRV8231A absolutely cannot achieve such accuracy. Could you give us some suggestion in how to improve current test accuracy to meet customers needed.

![]()

I wonder if we could suggest customers to test current with I-V converter. But that will lead low efficacy. Do you have any better suggestions?

And I want to figure out in what stage should we suggest customer use internal FET. Is there a power or torque threshold in distinguishing whether to use the internal FET or the External FET solution.

BR,

Peng