Other Parts Discussed in Thread: DRV8702-Q1, DRV8706-Q1, DRV8705-Q1, DRV8703-Q1, DRV8701

Hi Team,

I’m evaluating the DRV8873 motor driver for my project and would like your confirmation on a few points before finalizing the design.

My application involves driving a 24 V, 8 A brushed DC motor with high torque. The motor position will be controlled through an external accelerometer, so precise speed and direction control are required.

Could you please confirm if the DRV8873 can meet the following requirements?

-

It should be capable of supplying 8 A continuous current without thermal issues.

-

It should operate reliably at 24 V nominal motor voltage.

-

It should support motor current sensing for monitoring and control.

-

Regarding the interface, the datasheet shows SPI, PWM, and GPIO logic options — can you clarify which interface is used for:

-

Reading current sense data

-

Fault detection and status feedback

-

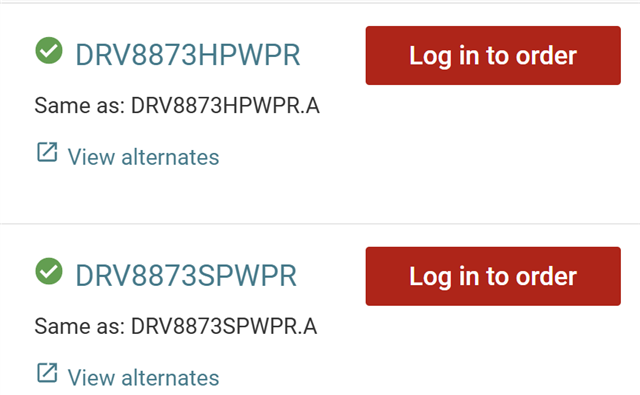

Also, if the DRV8873 cannot fully meet these requirements, please suggest an alternative TI motor driver suitable for a 24 V, 8 A brushed DC motor with current sensing capability.

Best regards,

Dhruvit