Hi. I have been looking at the eval kit for the DRV8840, with the intention of using it to drive a TEC (thermoelectric cooler).

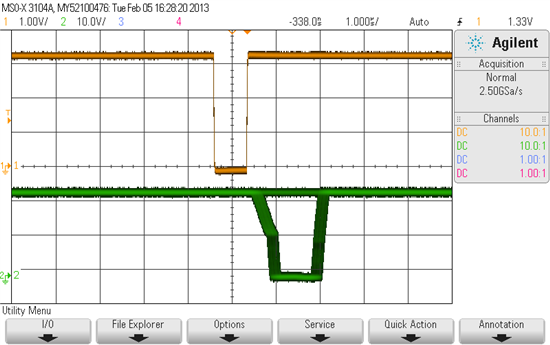

There seems to be quite a lot of 'jitter' on the output waveform, compared to the input PWM from the MSP430. This gets worse at very high duty cycles, to the point where there seems to be some LF modulation going on. Unfortunately, this starts to give audible noise from the L-C filter I have between the output and the TEC.

In the image below, top trace is the 3.3V PWM on the enable pin, bottom trace is on OUT2 with respect to GND.

I have the current limit disabled as best I can (I0-I4 all high, VREF to 3.3V). I tried shorting out the sense resistor just to be sure, but it made no difference. It also makes no difference if the DRV8840 is connected to a load or not.

Is this normal, unavoidable behaviour for this part?