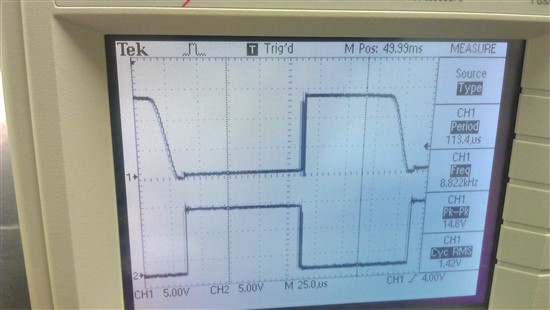

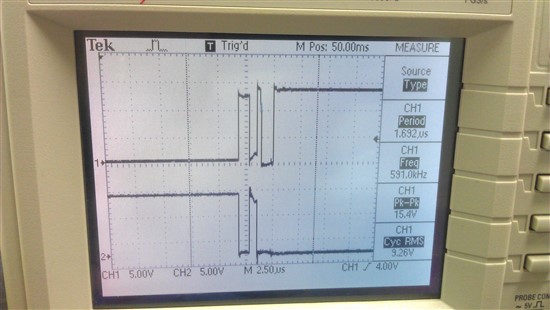

We're using a DRV8432 in a Dual FB, CBC current limit configuration. We are experiencing problems when we change the current limit resistor. Originally, we started with a 22k resistor and operations work as expected. When we try to adjust the CBC with a 47k resistor (we are trying to limit current to around 6A per motor), we see reduced function and sometimes freezing. We put an scope on the motor ports while the motor was attached, and you can see power on one of the poles start to collapse. We are running PWM at about 10khz.

This is our schematic:

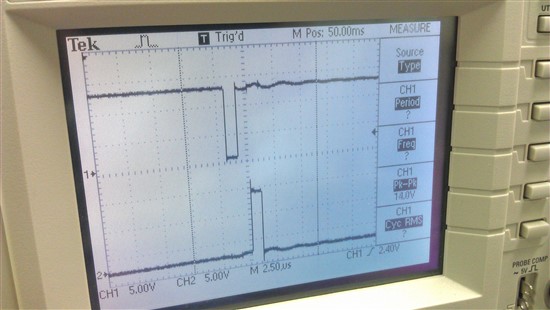

And these are some shots from the scope: