Hey guys,

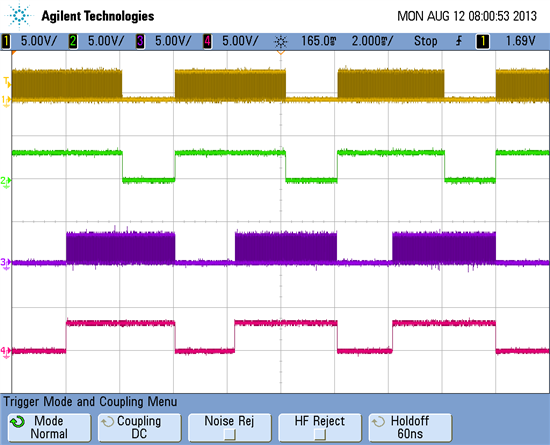

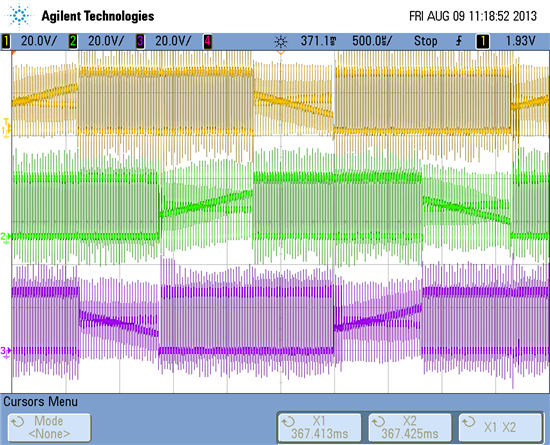

I have a custom PCB based on the design of the DRV8312-C2-Kit (with the 8332) being ran by a TMS320F28335. While my motor runs great unloaded at a constat speed, I keep shorting the chip while I try to start, stop or change the direction of the motor on the fly. Both my PVDD and GVDD supplies current limit, and I measure shorts between a bunch of the pins (bootstrap caps, PVDD to GVDD). I was wondering if this could be due to some back EMF or going over the absolute max ratings maybe (any of the -.3V ones, specifically).

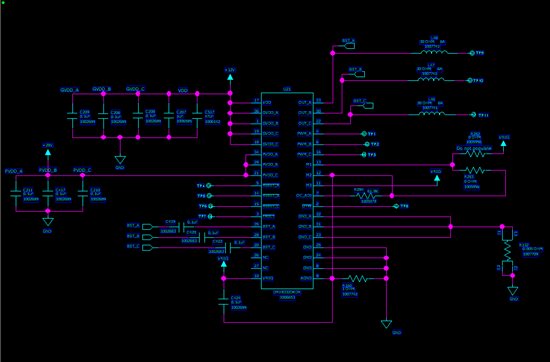

I don't think it's a software issue, as I can run my code on the eval board without any problems. Do you guys happen to know any common causes of this type of failure? Are diodes recommended between the OUT_X and GND_X pins to maybe help with any negative voltage spikes? I can share my schematic, but I have done some mods on the board, so it would have to be fixed up first.

Any help is appreciated.

Thanks,