Hi,

I'm using the DRV8811 for driving a stepper motor;

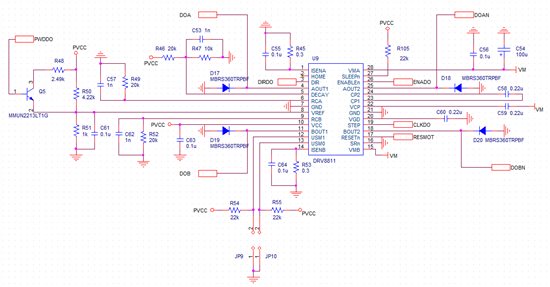

I'm using the following circuit:

when PWDDO on the base of Q5 is 0V, VREF on U9 is 0.958V and Ichop is 0.399A - in this condition, the motor is stopped (holding condition);

when PWDDO on the base of Q5 is 5V, VREF on U9 is 1.949V and Ichop is 0.812A - in this condition, the motor is moving (running condition) in 1/4 step;

the motor's maximum current is 1A;

VM=24V;

PVCC=5V;

the circuit works fine but the motor's mean temperature is really high: 50°C;

this circuit is designed to replace an old circuit that use Toshiba TA8435;

the old circuit drive the motor with the same current limit in the same conditions: holding condition:0.5A, running condition @1/4 step:0.8A but, with the old circuit, the stepper motor mean temperature is smaller: 39.8°C;

1) which can be the cause of this behavior?

2) the increase in temperature may be due to the chopper frequency?

3) What happens if the chopper frequency is too high?

4) this circuit, must drive different motor with different characteristics; there is a rule of thumb to determine a good value for C62-R52 and C57-R49?

thanks in advance

Fabrizio