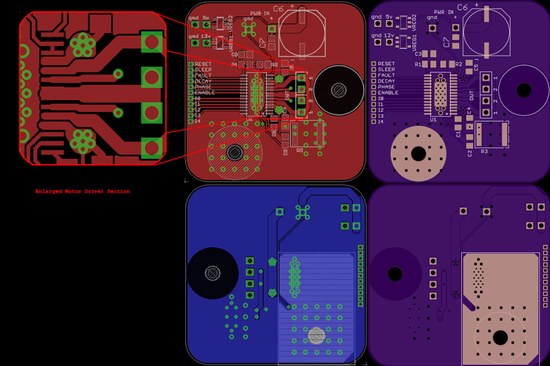

hey guys, I am working on a project, and would like someone with more motor experience to look over the board real quick before I send it off to be made. just to make sure i didn't miss anything silly.

the driver is a DRV8840 the micro-controller will be a MSP430G2553

the motor is 18V DC Brushed and draws around 4.5 amps

because of the small board size (40mm square), I plan on mounting a heat sink directly to the back of the board

I studied the files for the evaluation module and I think I emulated it close enough.

I'm not a big fan of the pin layout on the chip having the pins split apart and having to connect them together in a small space is difficult with the high amperage traces and what not.