My customer has the following question on a DRV8800 driver - can someone help address? Thank you!

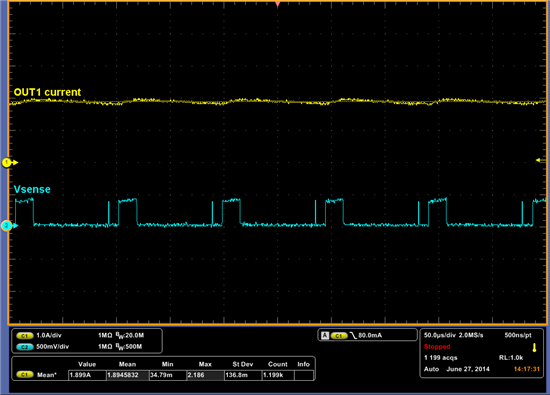

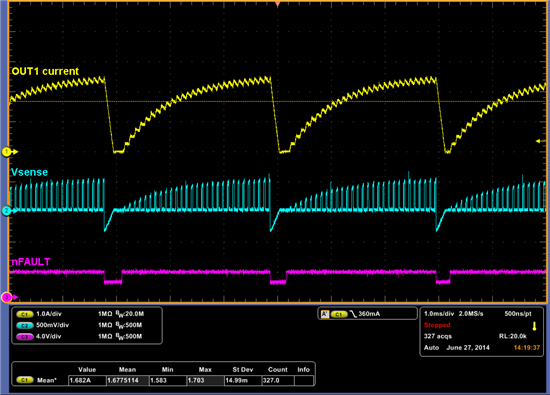

“I am driving a regular 12 volt motor that pulls 150mA when the motor is stopped. I have a 4.99 OHM resistor from SENSE to GND which would fault at 100mA according to the data sheet. As soon as I plug in the 12V it immediately faults and puts the motor into current recirculation and I am measuring on 74mV on the SENSE pin. I am wondering if the data sheet is wrong and the SENSE voltage is actually 50mV instead of the 500 mV they claim on the data sheet?”