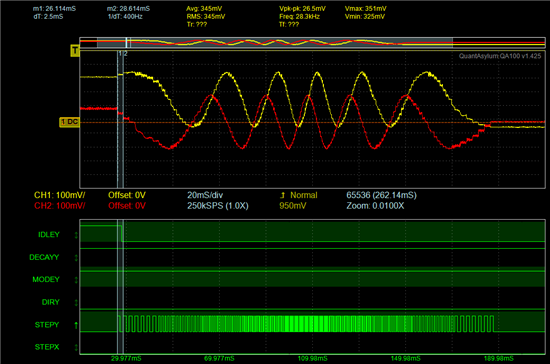

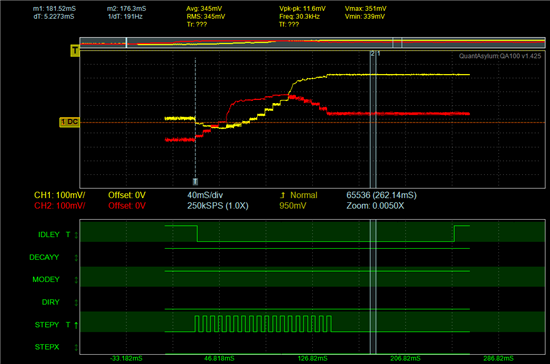

Hi, I'm having a problem with the DRV8825 that I don't understand. In the plot plot below, you can see phase A and B currents and also the step signals. The IDLEY signal isn't important. The DECAYY signal "high" means the HW is in mixed decay (floating pin). The MODEY signal is the MODE0 and MODE1, and MODE2 is tied low (which means this is 1/8th step mode). StepY starts at 400 Hz pulse rate, speeds up and then slows down.

So, the summary for this first plot is that things seems reasonable and the motion sounds/feels/looks smooth.

The problem I'm facing is that for single or double 1/8th stepping the steps are nowhere near close. There is a big step that sounds like a clunk, and then very faint ticks. The clunk definitely moves the shaft, the ticks are much smaller moves. The patterns seems to be CLUNK tick tick tick tick CLUNK tick tick tick.

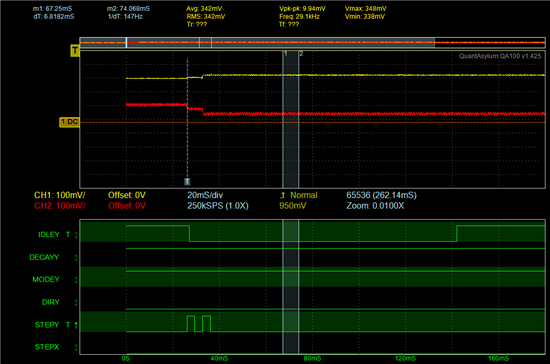

Looking at a tick (slight move, about what I'd expect) I see the following:

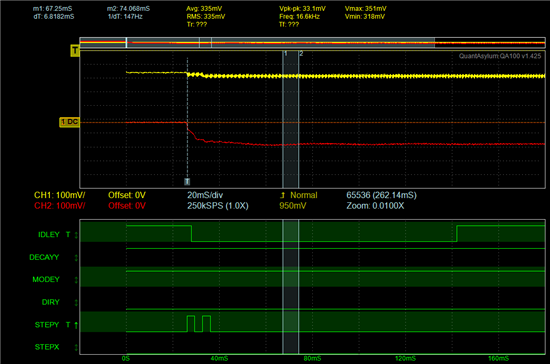

In the above, note there are two discrete changes in the phase currents. Makes sense. Feels right. But every 4th movement there is the clunk (bigger jump), and here is what that looks like:

Note the yellow phase current again exhibits two discrete steps, but the red phase current has a sloppy transition through its step and then moves to a totally unexpected value.

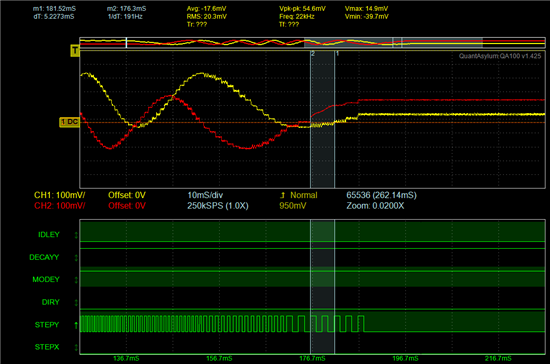

Now, back to a variation of the first capture: If you look closely, the bigger moves will also show regions of this strange behavior. In the capture below, you can see it marked during the slowdown (red trace), but you can also see it in the yellow trace during the acceleration.

And one more weird one:

Any idea on what might be going on? TIA for any insight.