Hi,

Im using the drv8711 evm with the gui to take a closer look at some torque regulations.

ST8918 from nanotech and measured to about 5 Amps at 13Nm with the origin hardware.

The supply is ratet at 48v and 10 Amps and testet with origin hardware.

My addaptive settings in the board are:

- Mode 1/128 Step

- Gain: 10

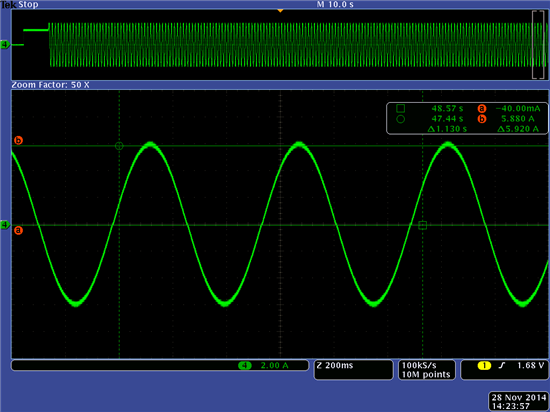

- Tourque 128 => makes 3,78 Amps

- Decmode: Fast Decay

- Target Speed: 26880 pps => makes 63 rpm with 1,8° / step

- the rest of settings are default

The Operation:

- everything on startup is normal the motor reached the 63 rpm with about 2Nm

The Issue:

- Until about 3-1 min the motor stops suddenly with the bpdf fault.

- This issue is repeadable and clearable by clearing the bpdf bit in the statusregister (0x07)

Questions:

- does the evaluation module could give out 5 amps ? The datasheet doesnt say anything about that. (the mosfets coud give 5 Amps)

- What conditions relay to the predriver fault ? THe datasheet only tells something about exessive current is detected but not how much is it and what could i do to prevent this

- the issue feels like a heat problem, because the time of the fault is shoten by fast clearing the register and repead. Is there any connection?

- Could you give me some hints to optimise the motor to 10Nm 5Amps ?

Thanks, Johannes