Hello,

I am struggling with an issue I believe is mid band resonance. I have used the DRV8711 very successfully to drive a number of motors up to very high speeds and have been very please with the documentation and support surrounding this product. I am now at a sticking point!!

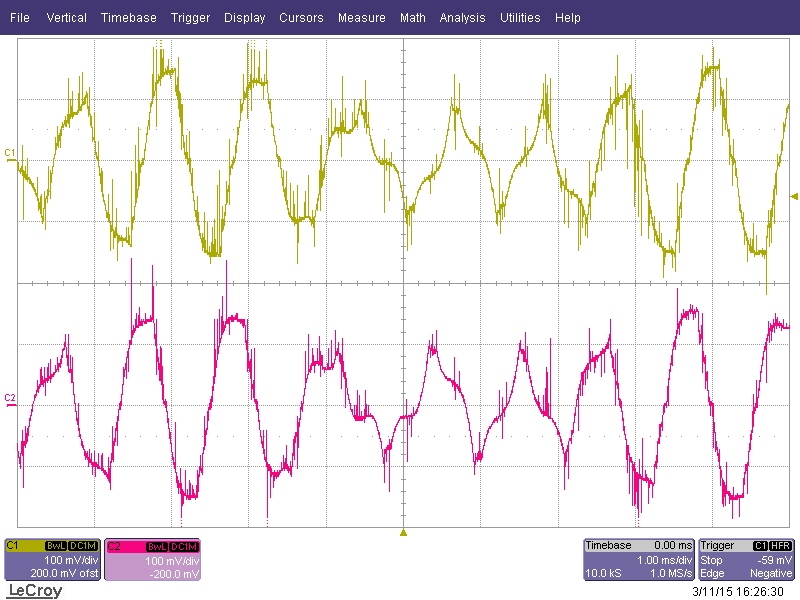

Some motors that I connect to my stepper motor driver suffer from what I believe is mid band resonance. At a speed (dependant on supply voltage, motor type and inertia on motor shaft) between 450 - 600 rpm the current wave form starts to look very odd, there is lots of audible noise and the motor then stalls. This comes on very suddenly, before which there is no sign of any issues. If I add inertia to the motor shaft or reduce the target current the affect is supressed somewhat, as expected. Other motors of similar sizes and characteristics from different manufactures can be run up to 2000 rpm without a problem.

It would be nice to find a solution for these motors. Have you had any over users experience the same issue?

I have done a fair amount of experimentation with the driver IC settings to improve matters but have not had much luck.

Is there a decay mode which starts a new chopping cycle when a new step signal is received in indexer mode? (I believe I read this somewhere but can seem to confirm it)

Can provide more information as required.

Many Thanks

Nick