Hi,

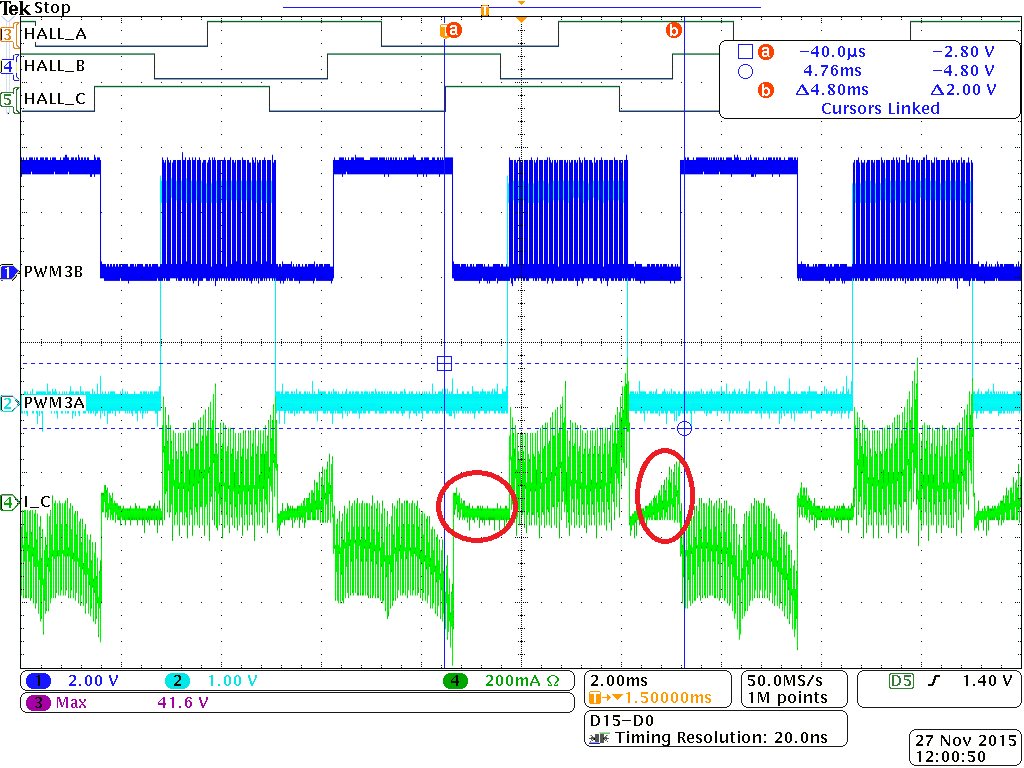

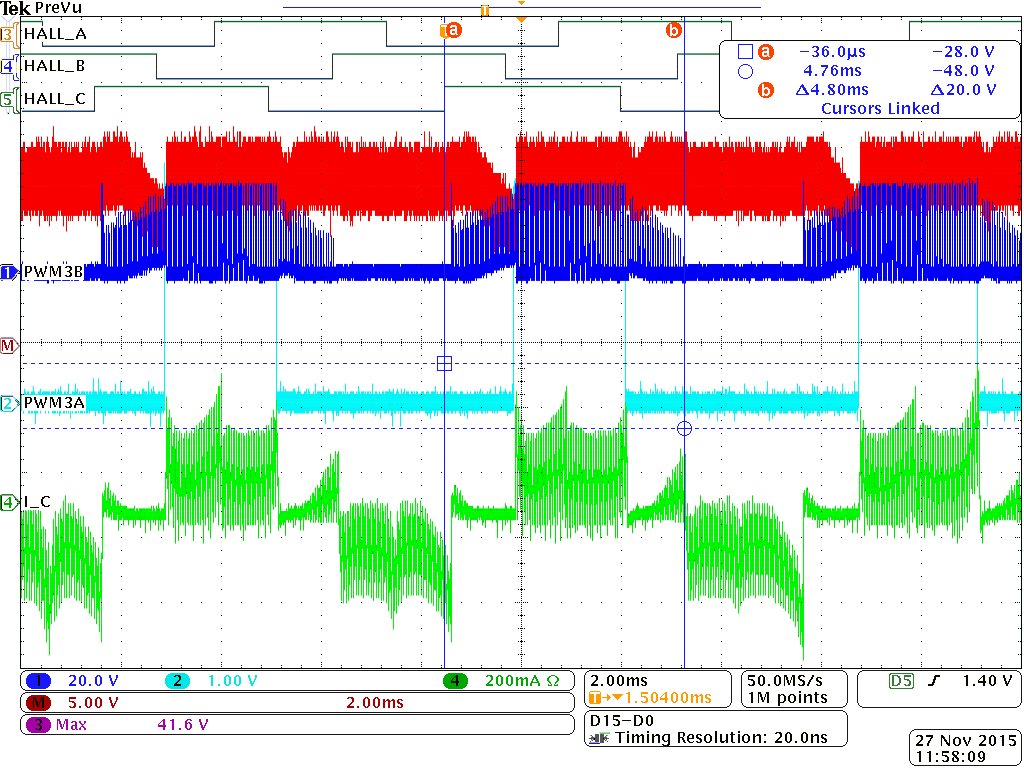

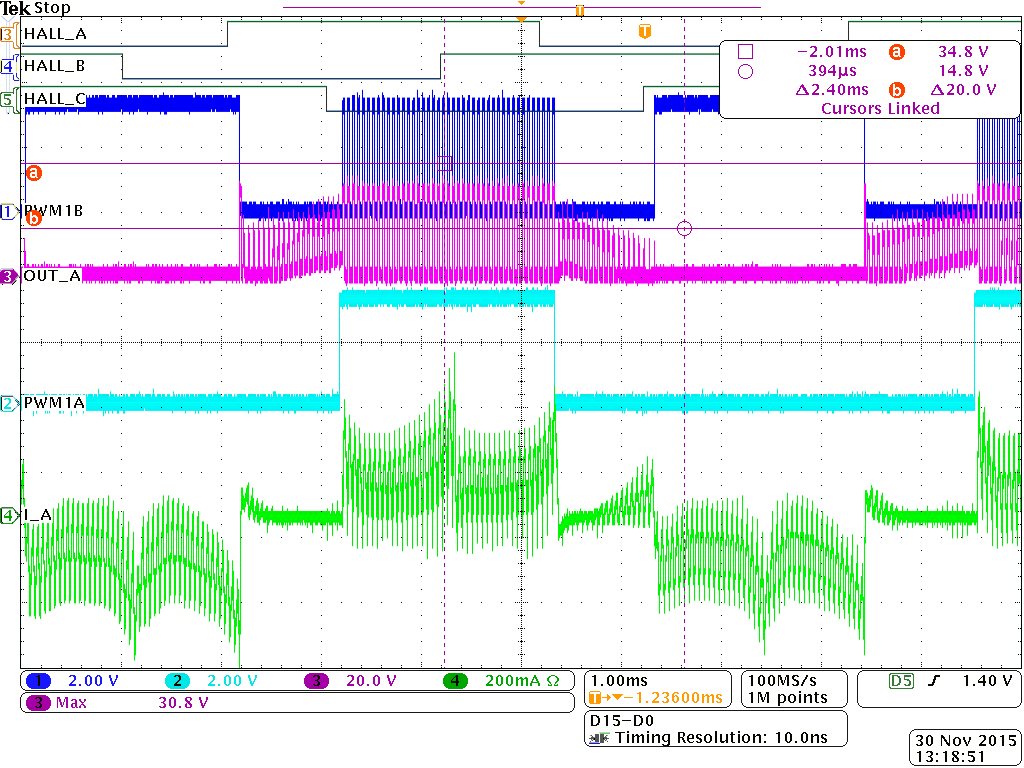

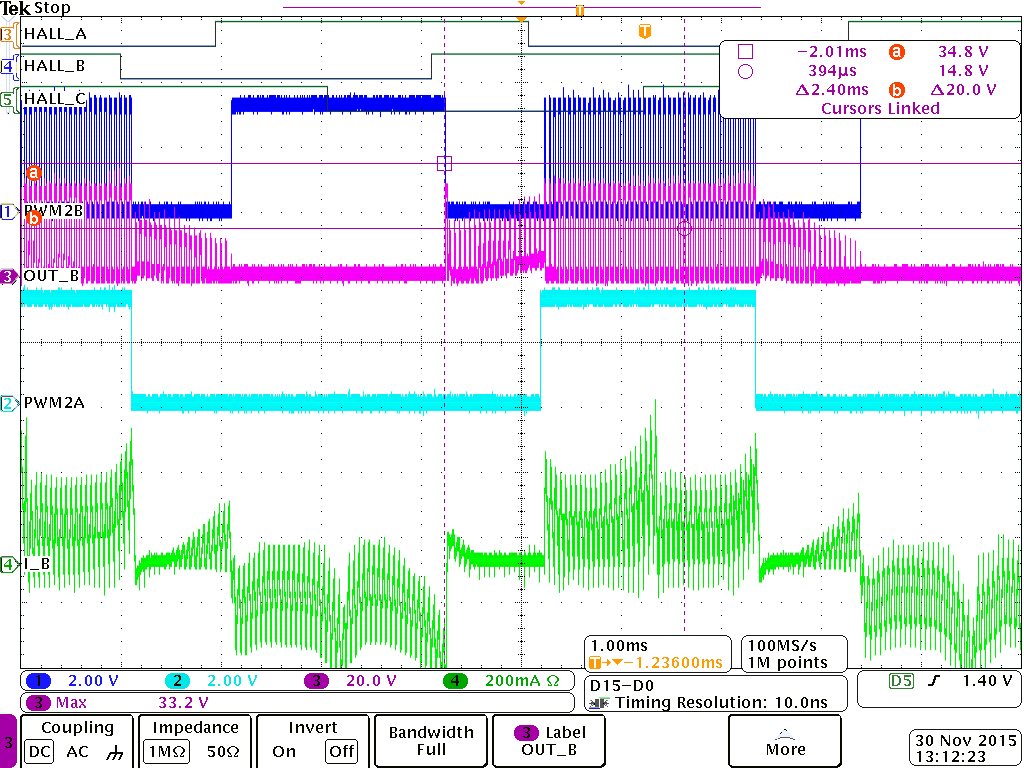

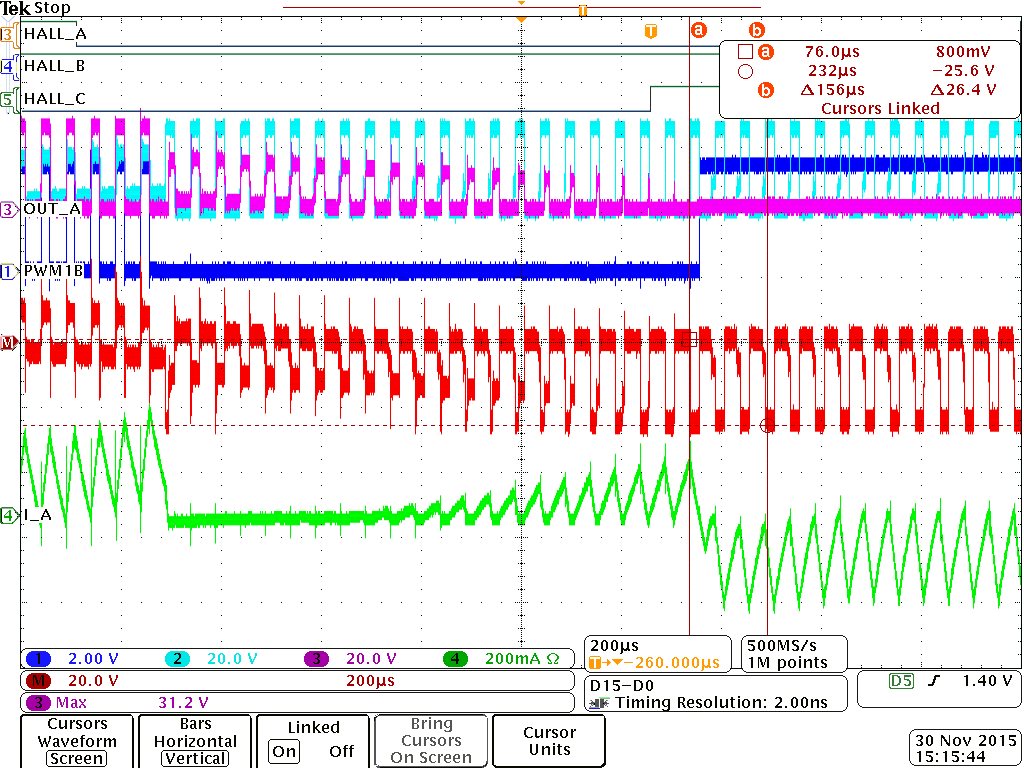

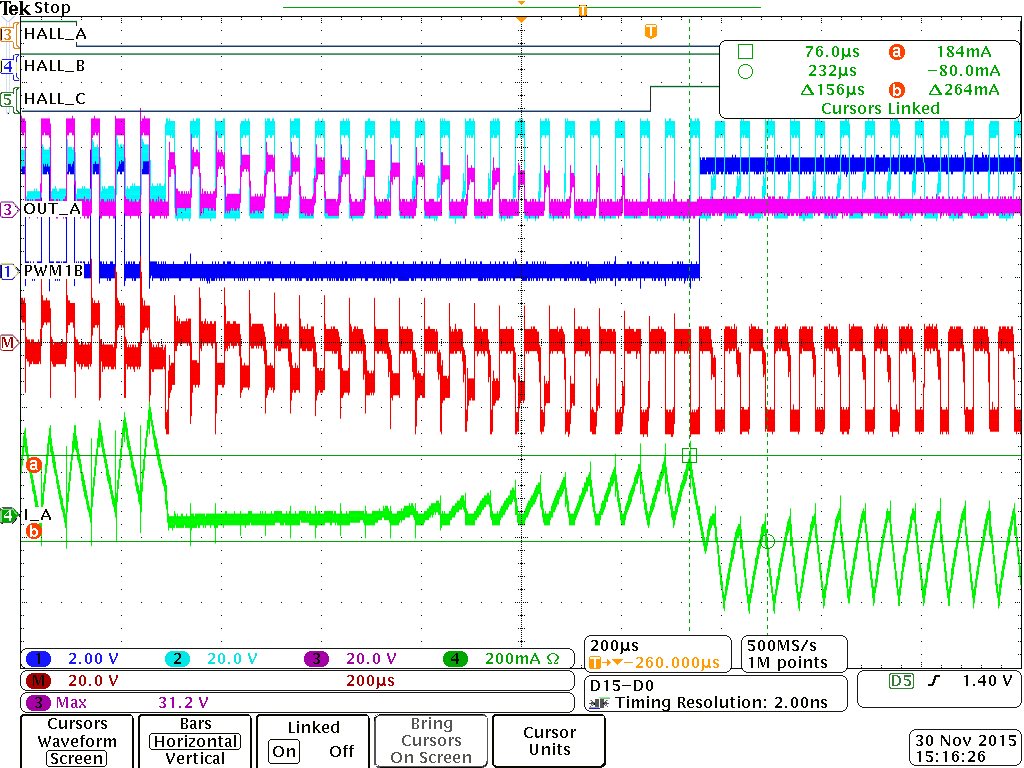

I have DRV8312-C2 kit. Using BLDC_GUI code, i get this current waveform for both the sensored and sensorless options.

Any idea, why current still flows on the red circled areas? Technically, at those instances, the current should flow on the high and low side FET (i.e. high-impedance state). Hence, in those areas, it should just be a flat 0 A level. The green curve is the current measured on phase C of the motor that came with the kit.

Any ideas?