Hi

I am using DRV8825 Driver IC , I have few questions listed below :

1. I am working on various frequency but stepper motor supports only certain frequency at which the motor rotates. Can you please let us know what is the maximum frequency the motor can run.

Motor Spec Below: catalog.orientalmotor.com/.../pk244pda-p5

2. Also, when the Motor is connected and when we try to run the motor and Driver IC gets heated up. What is the solution to avoid thermal dissipation.

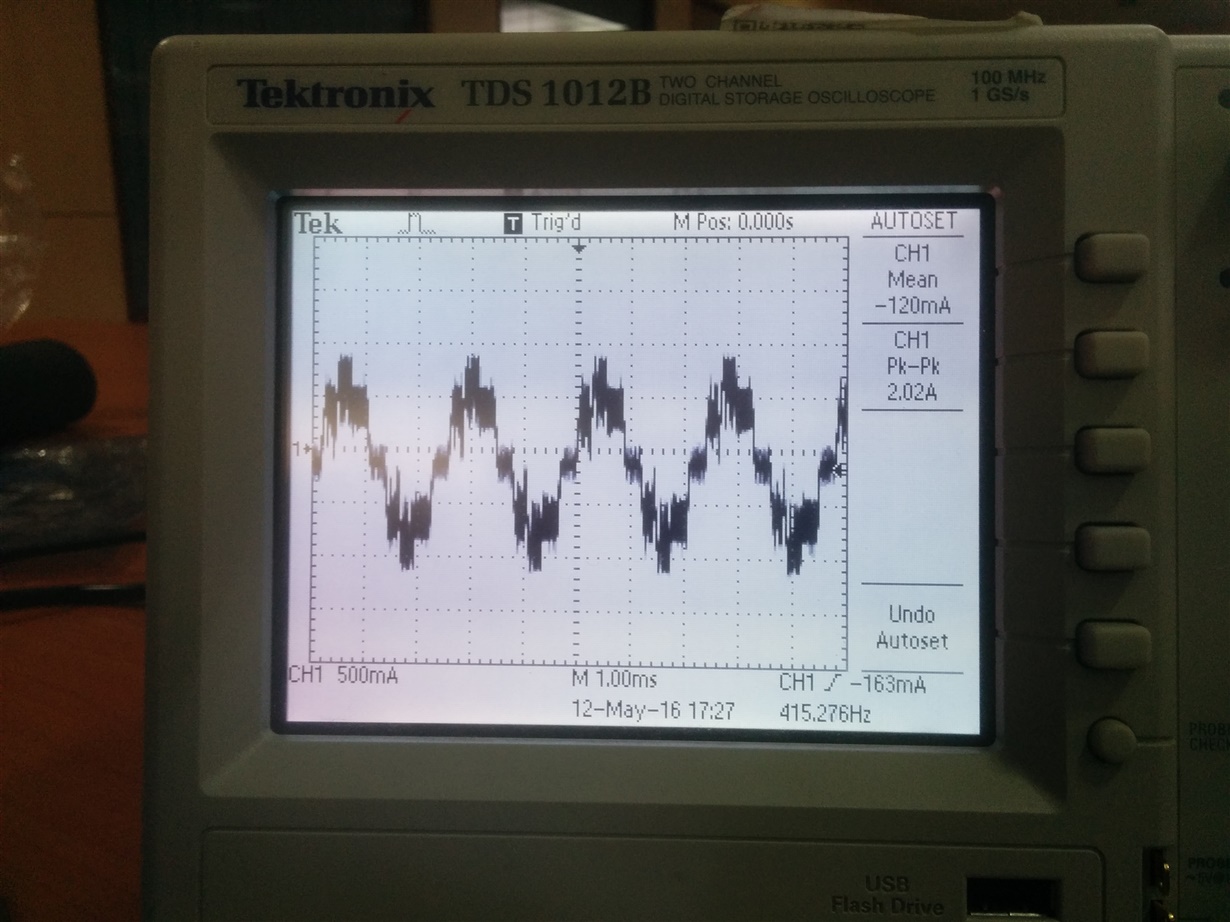

3.We are trying to run motor at 100 RPM by giving 1.6Khz full step, But across coil we are observing 13Khz in spite of giving full stepping. We have set the Vref pin to 2.4V with Ichop current set to 1.45A. Is this ok for attached motor spec ?

3. We are providing the Ichop of 1.4A but in ammeter its showing 0.5A which is contradictory. Is this the intend way to run.

Thanks

Pavaman. P