Hello TI,

I have a couple questions for the motor experts. I have reviewed both the DRV8711 datasheet and Quick Spin Tuning guide pretty thoroughly.

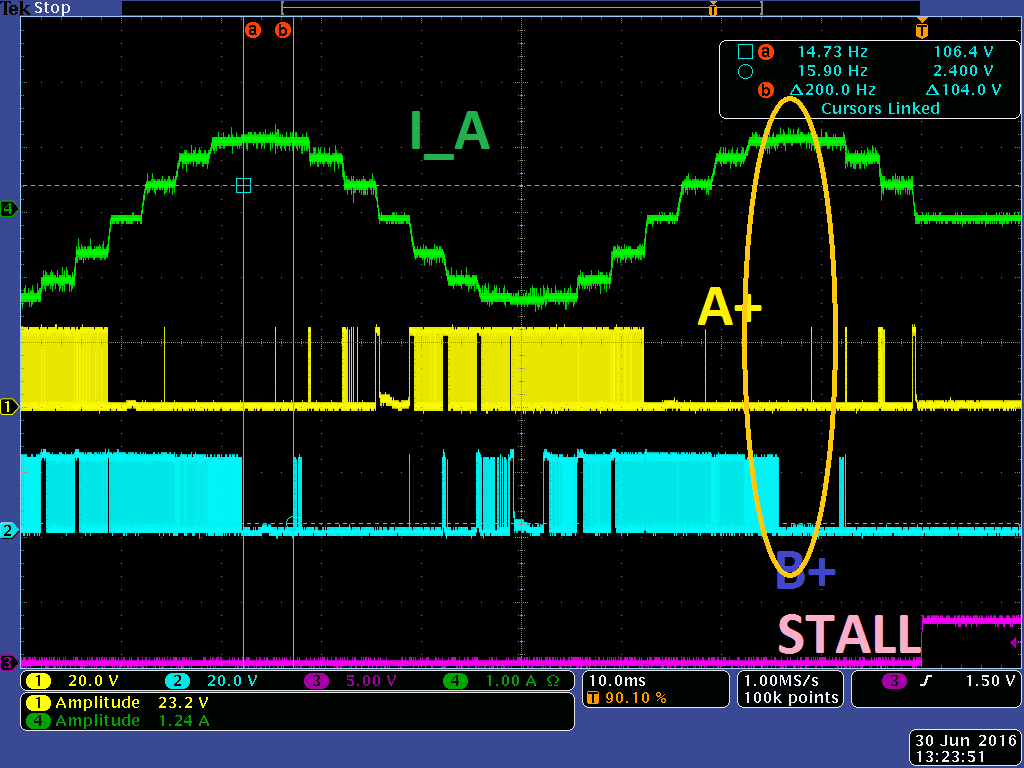

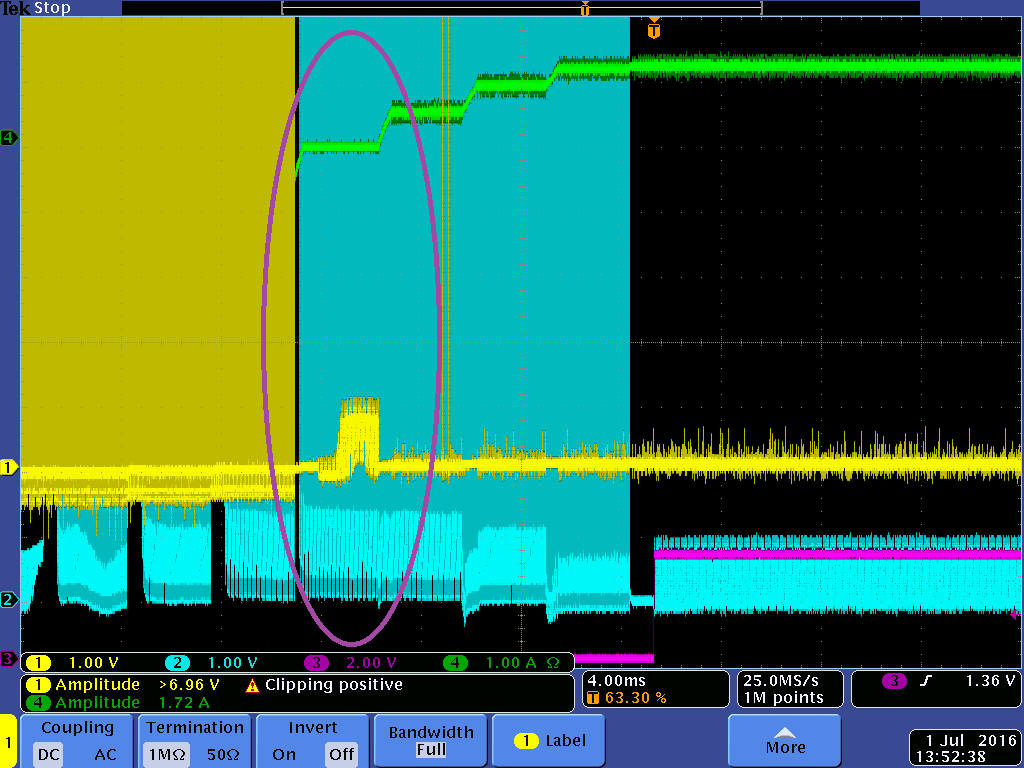

Furthermore I did a good feasibility study with the DRV8711EVM some months back... As reference https://e2e.ti.com/support/applications/motor_drivers/f/38/p/442973/1592060#1592060

Regarding general Motor Current...

I'm using a PK264 Stepper (datasheet & Torq curve below) with the following specs:

-Current/phase: 1A/phase

-PCB VM: +24V

-Mechanical Load: <= 0.15 Nm

-1/4step Microstepping resolution

1) Since this motor is specified at "1A/phase", what Full-Scale current should I be driving with the DRV8711? 1Apk, 1Apkpk, or something less than 1A?

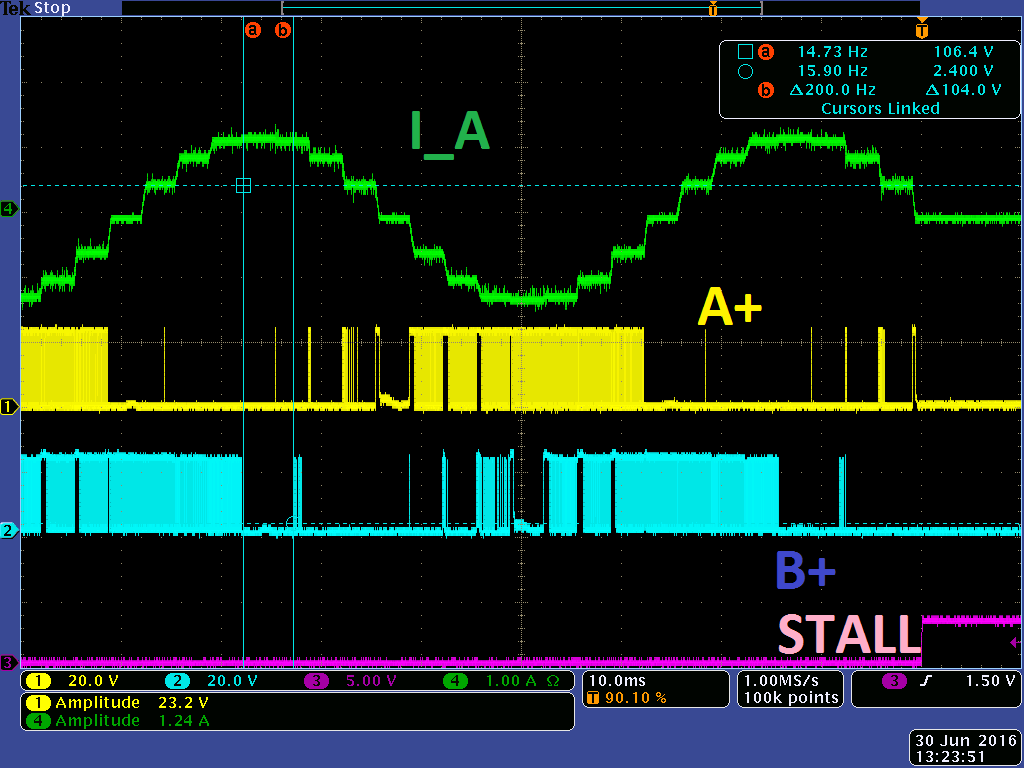

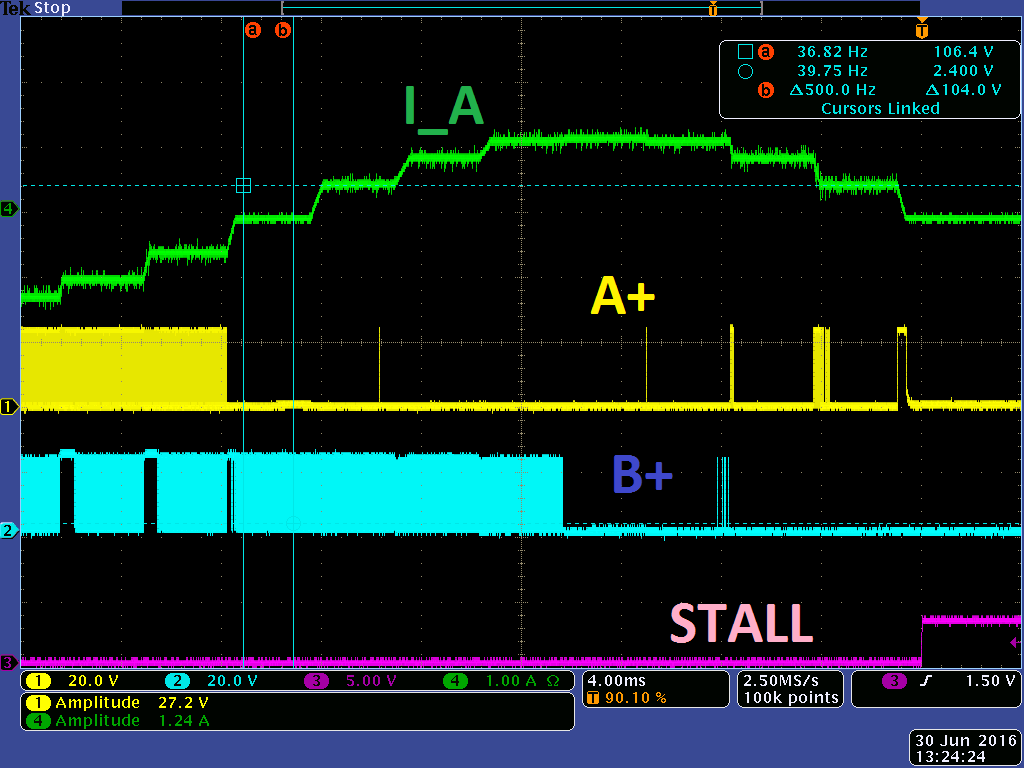

Regarding Integrated Stall Detection

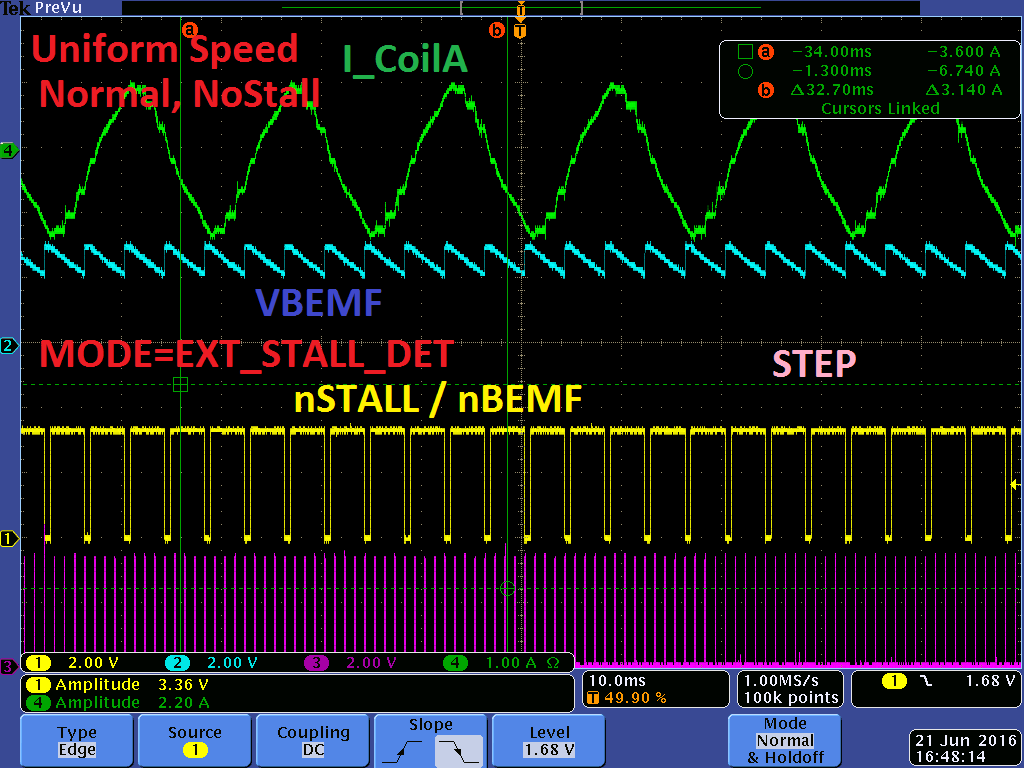

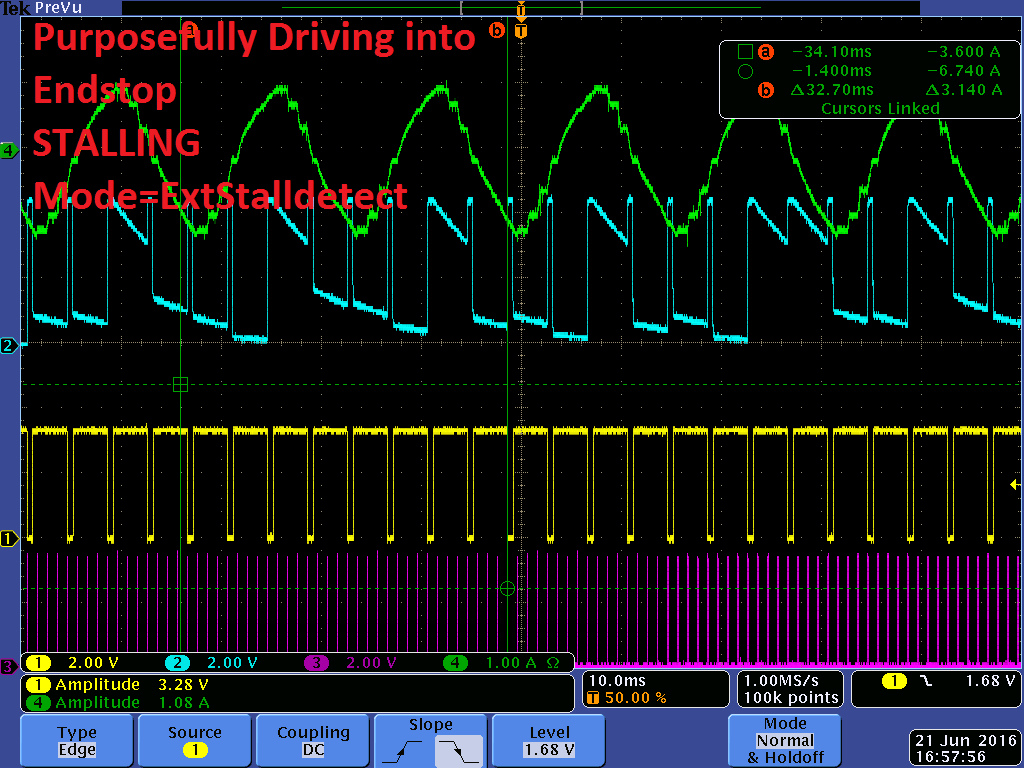

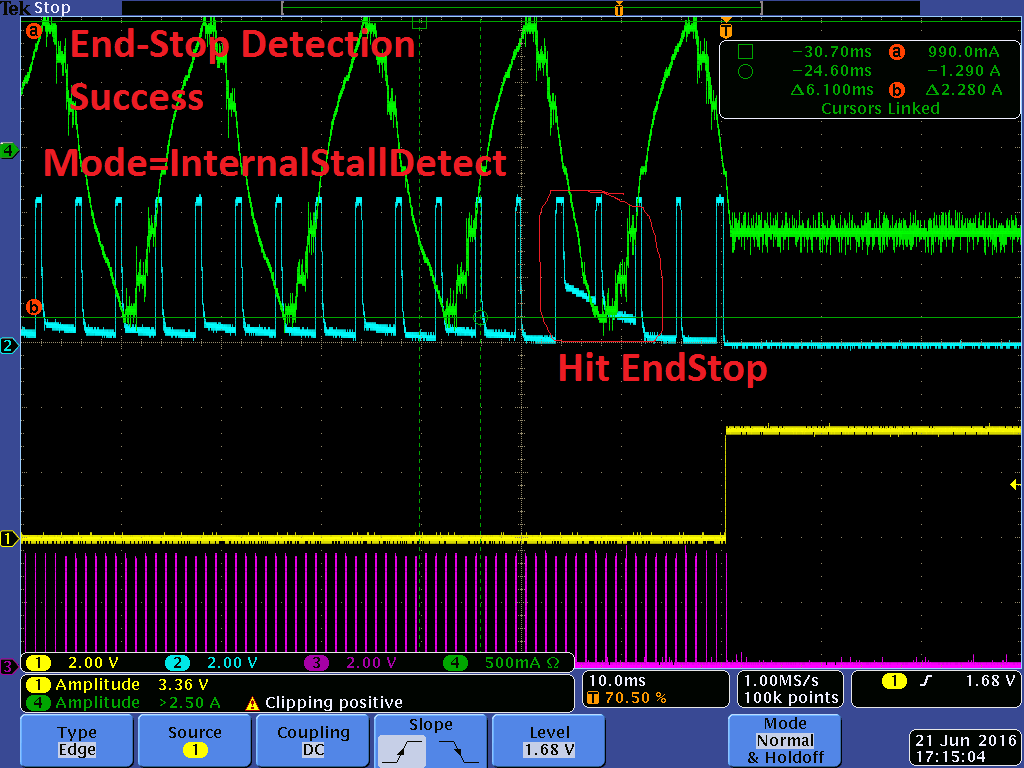

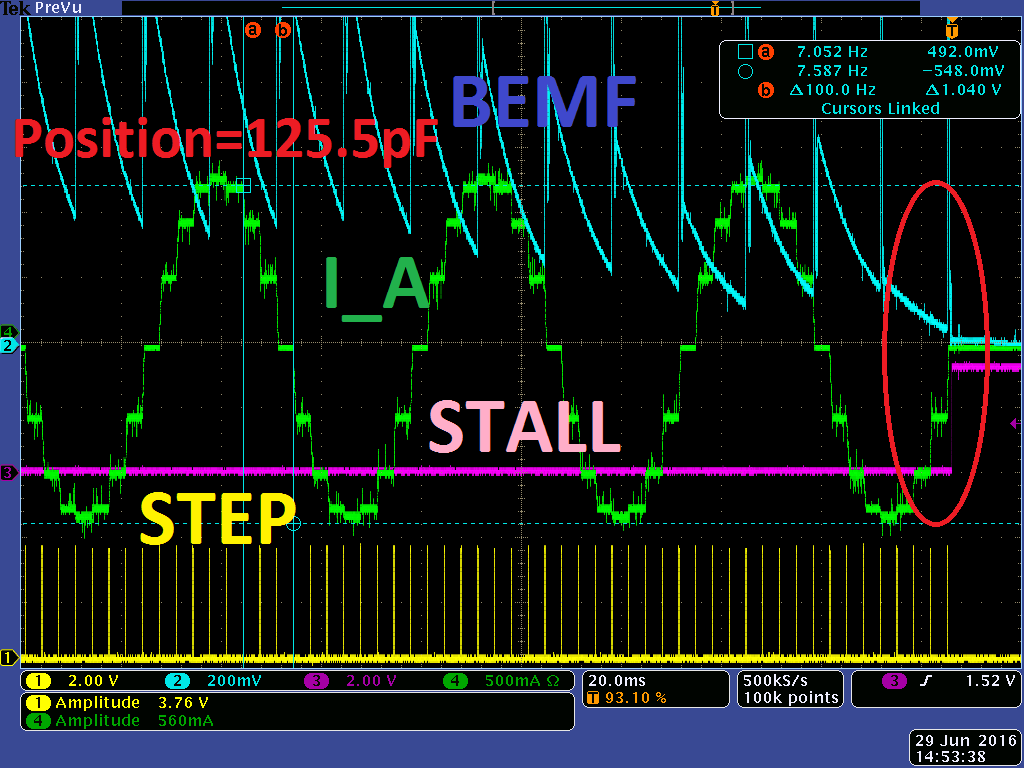

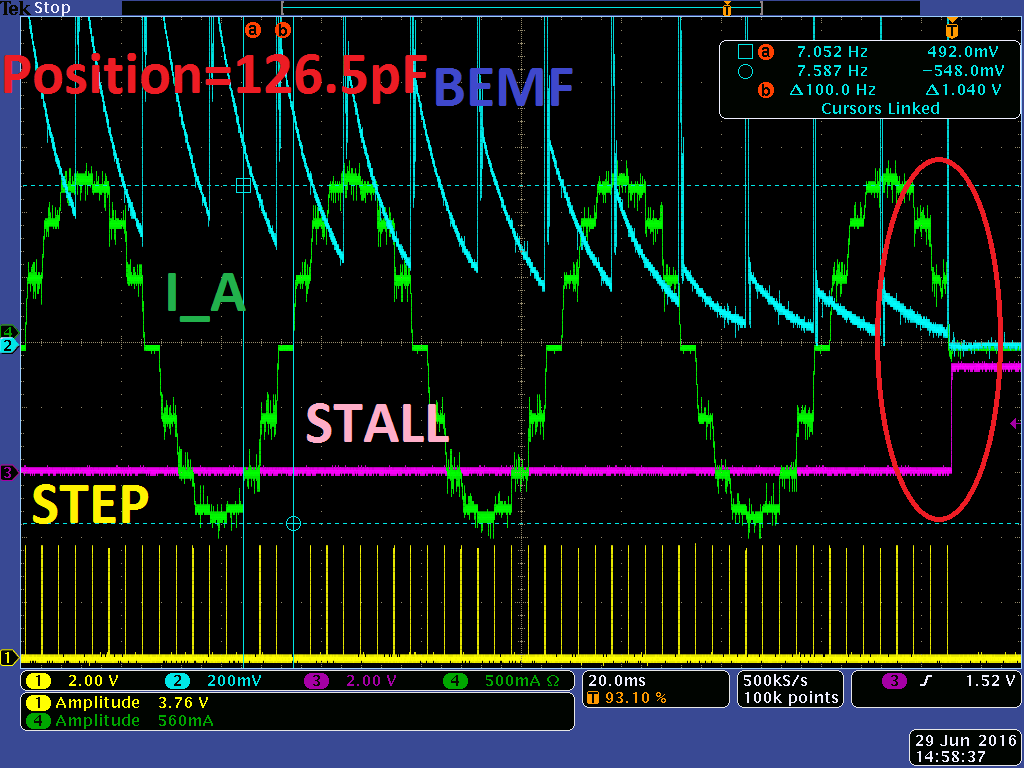

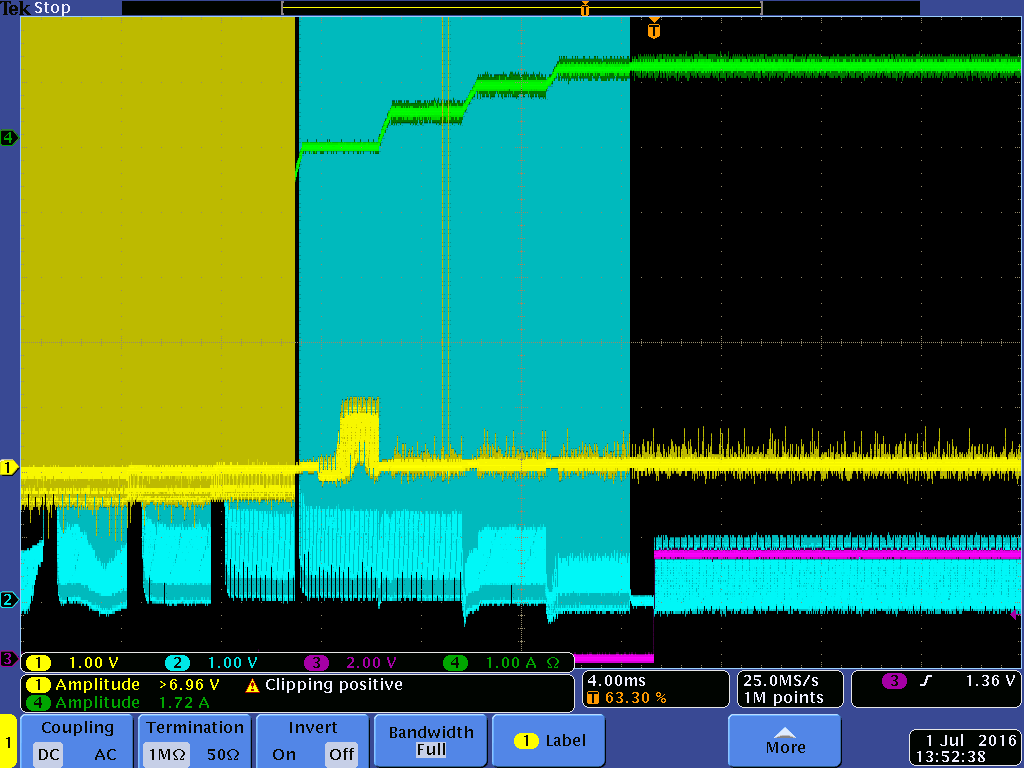

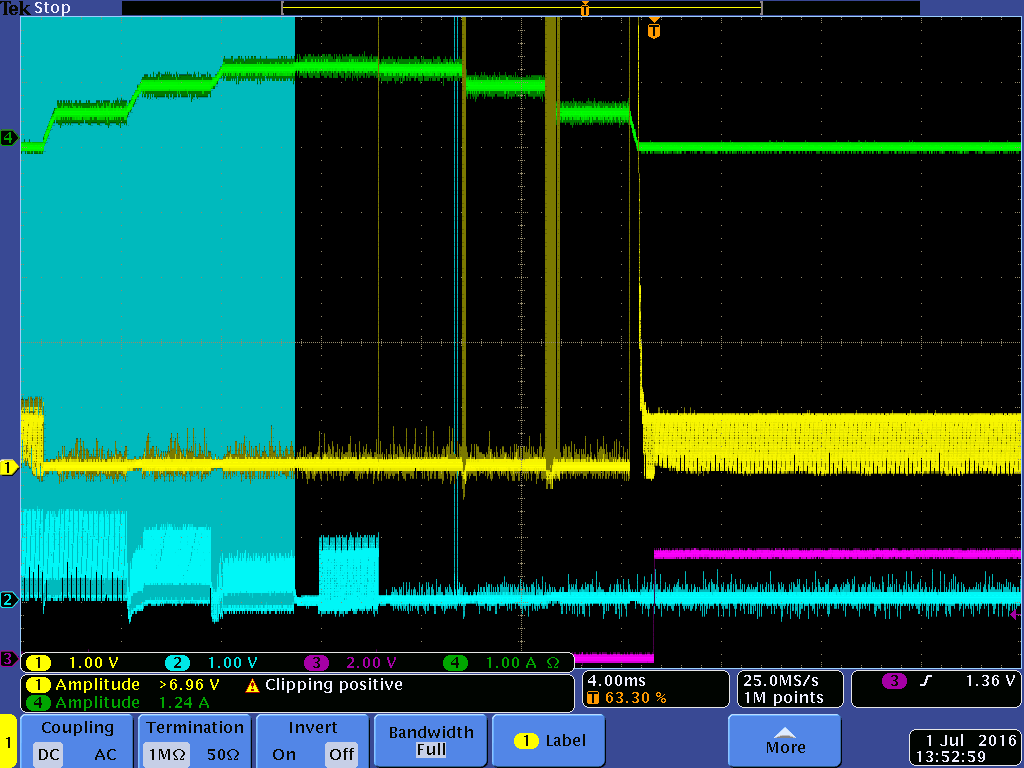

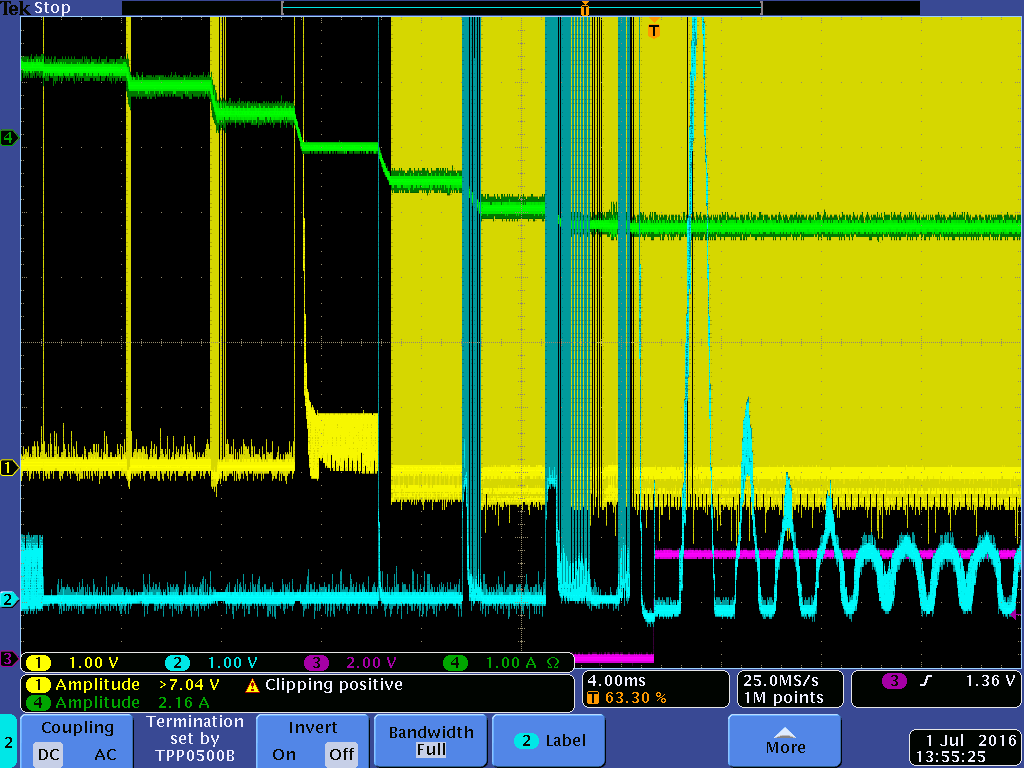

With the EVM I just wanted to prove I could get it working (which I did, see earlier forum post)... Now I'm trying to optimize for the product.

As an application, the goal is to use this feature as an "END-STOP" detection; our motorized system has a mechanical end-stop and I would like to detect this using nSTALL and stop. Hence the goal should be easier than detecting all motor stalls and more obvious BEMF levels (i.e. motion vs no-motion).

2) Can you clarify 'Step Time/Rate' in the statement in the DRV8711 Datasheet says "Step Time, or rate at which step input is applied to DRV8711, has to be greater than SMPLTH".

I can't tell if this means:

a. Tstep < Tsmplth, hence Fstep > 1/Tsmplth

b. Tstep > Tsmplth, hence Fstep < 1/Tsmplth

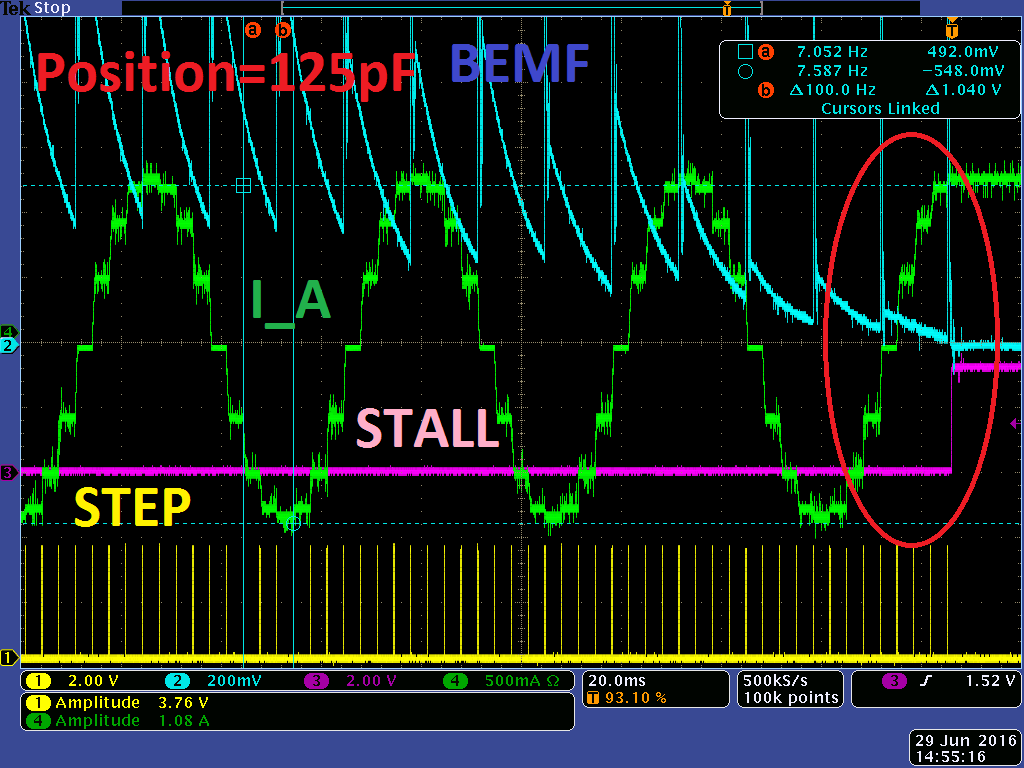

3) The Quick-Spin guide gives no recommendation for SMPLTH, other than the above statement. I have had better/worse success with different values with SMPLTH. Can you explain how I can find a proper value for SMPLTH?

4) In the Quick-Spin guide the recommendation is "Move the motor slowly... Now increase SDTHR or VDIV or both until STALLn becomes asserted... Increasing SDTHR/VDIV will make the stall detect trip at higher speeds.."

I am having difficulty getting the nSTALL to throw when the motor is moving slowly, even with VDIV=11 (BEMF/4), SDCNT=00 (first step), and SDTHR set to something small like 0x02.

Is there a way I can optimize this by looking at the analog signal in external stall detect mode?