Hi,

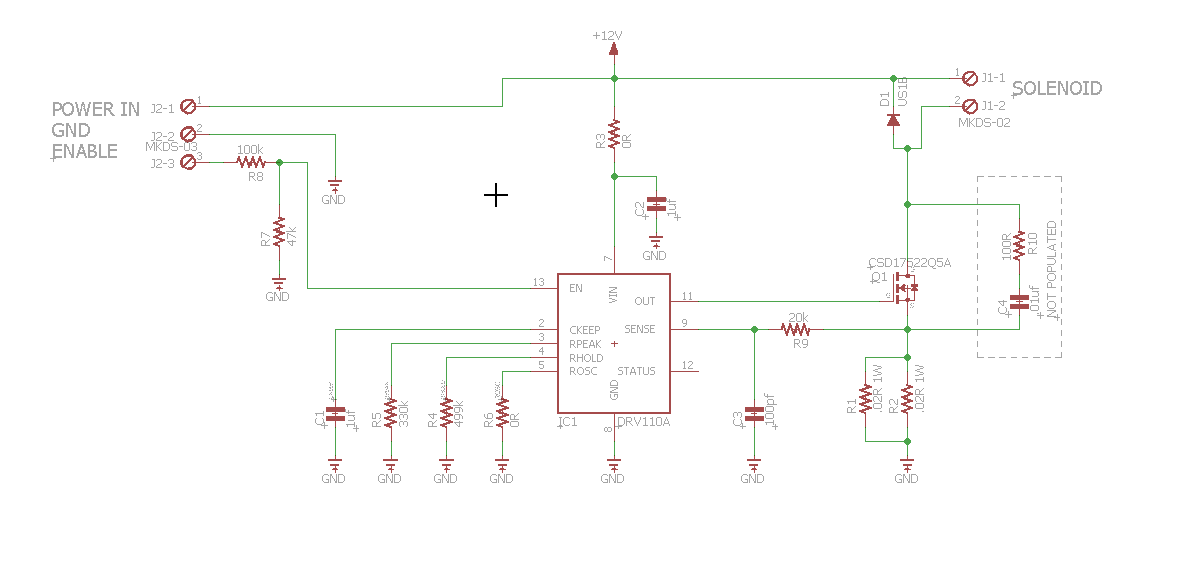

I got an application where I need to replace a relay controlled solenoid with a PWM driven one, to reduce current usage.

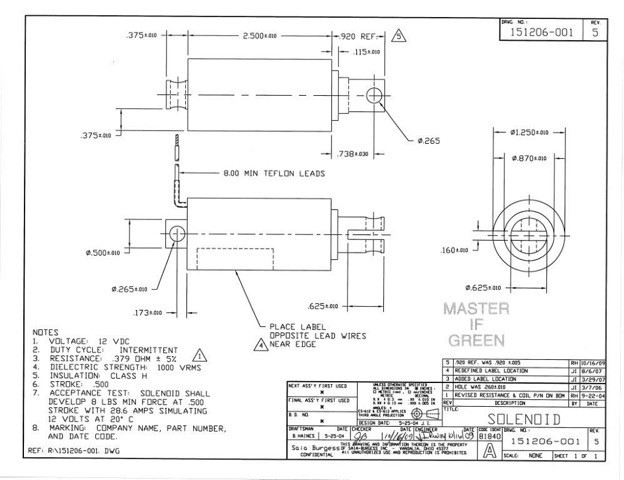

I'm waiting on the customer to give me the specs of the coil. But some real world testing I did, its 12v dc solenoid,

it takes about 10amps to engage the solenoid, yes 10A, to keep it in it needs at least 1 amp

(there is a mechanism that wants to pull it back out). So I would like Ipeak to be 10amps, and Ihold to be 1.5 amps

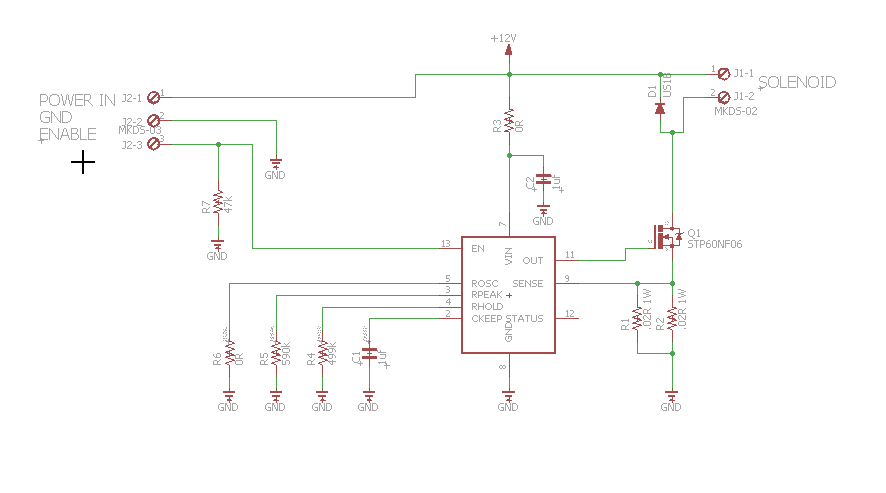

the mosfet I would most likely use is STP16NF06. Can the DRV110A (14 pin version) do this for me?

Thanks and awaiting answer

Mitch