Hello Everyone,

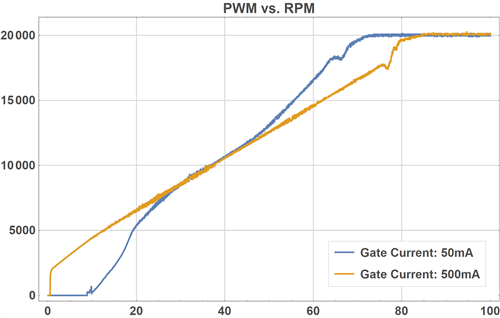

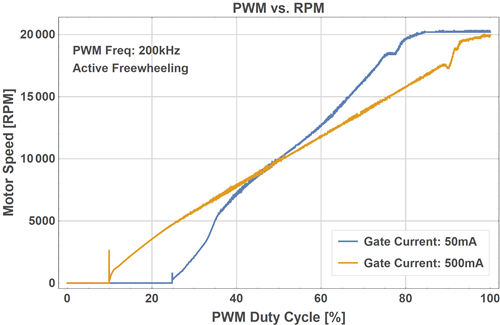

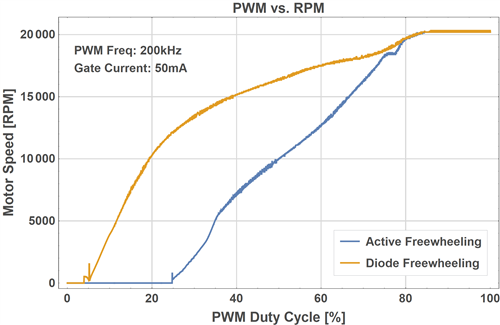

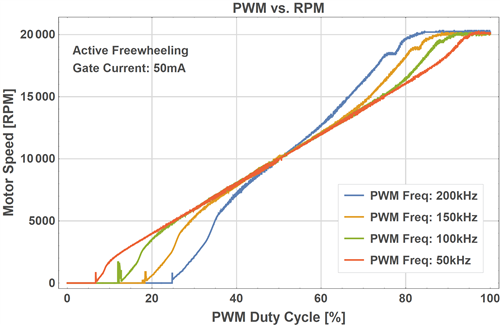

We are using DRV8305 for driving a BLDC motor in 1-PWM mode with a 200kHz PWM signal. We have observed sudden changes in motor speed in specific ranges of PWM duty cycles. There is a drop and then a sudden rise in motor RPM with increasing PWM duty in these regions. DRV8305 is operated with the following settings;

PWM FREQ: 200kHz

PWM MODE: 1-PWM

COMM OPTION: Active Freewheeling

DEAD TIME: 52ns

TDRIVE: 1780ns (for both high and low sides)

MOSFET: http://www.ti.com/lit/ds/symlink/csd18540q5b.pdf

MOTOR: http://www.maxonmotor.com/medias/sys_master/root/8825427656734/17-EN-241.pdf

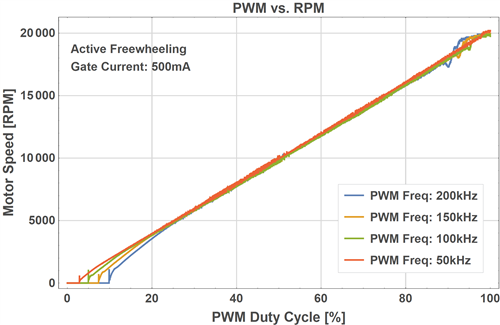

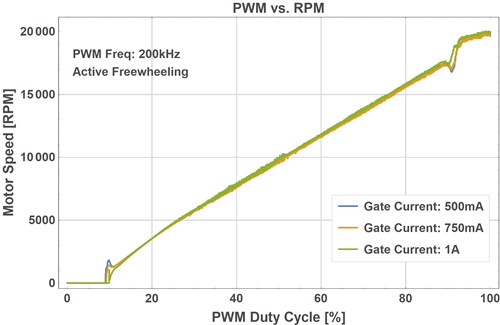

Following plots are obtained by slowly increasing the PWM duty cycle and logging the motor RPM,

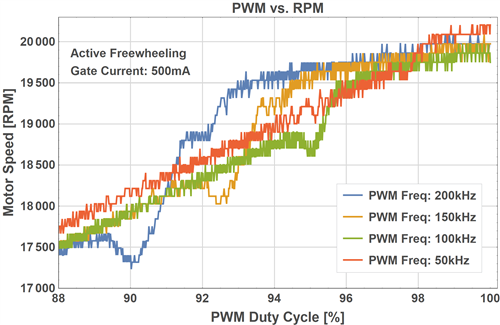

Especially the drops near the 17000 RPM region are problematic as we are operating the motor in this region.

Lowering the PWM frequency prevents this behaviour. However, as the R/L ratio of the motor is quite large (i.e. small electrical time constant), we prefer using high PWM frequencies.

Best Regards.