Other Parts Discussed in Thread: DRV10983-Q1

Hi,

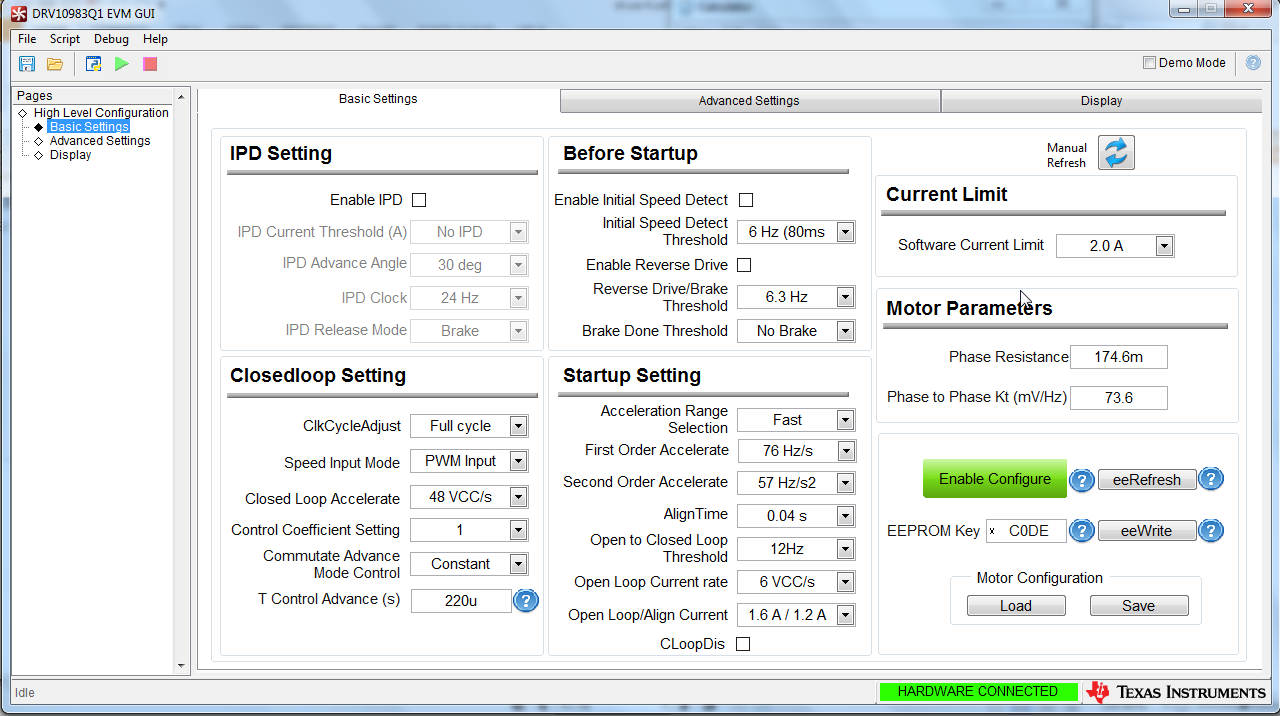

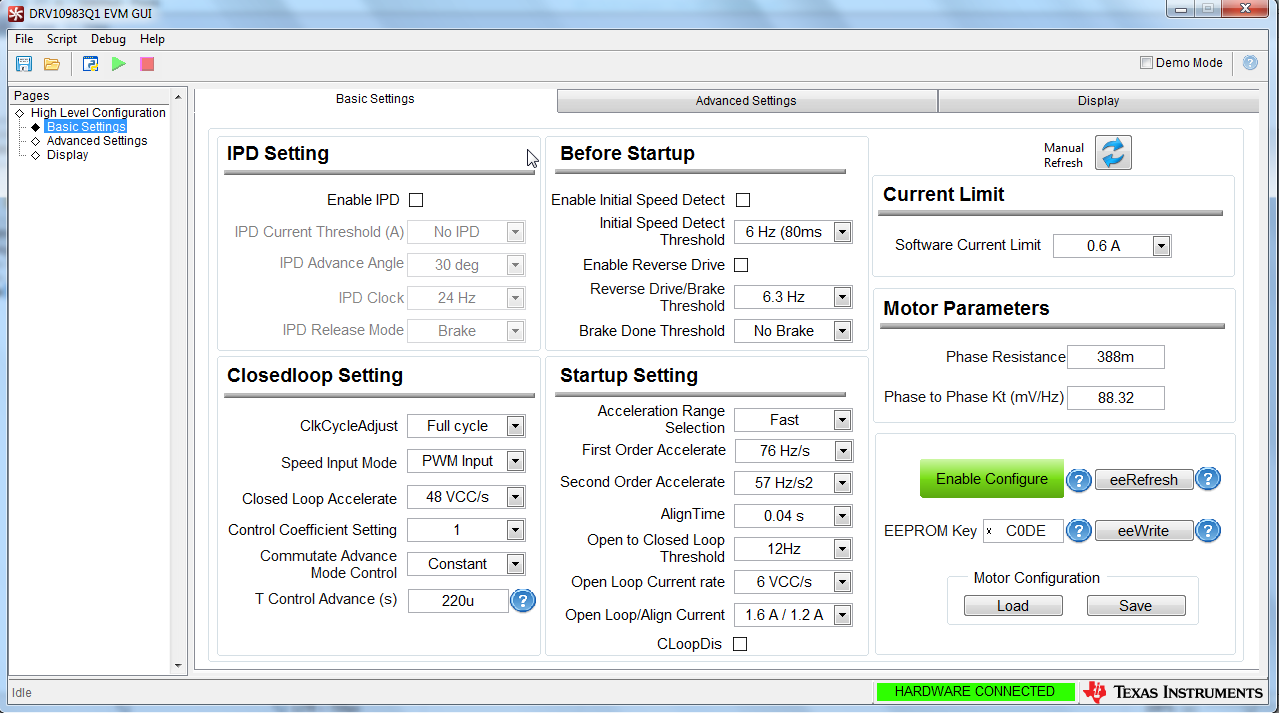

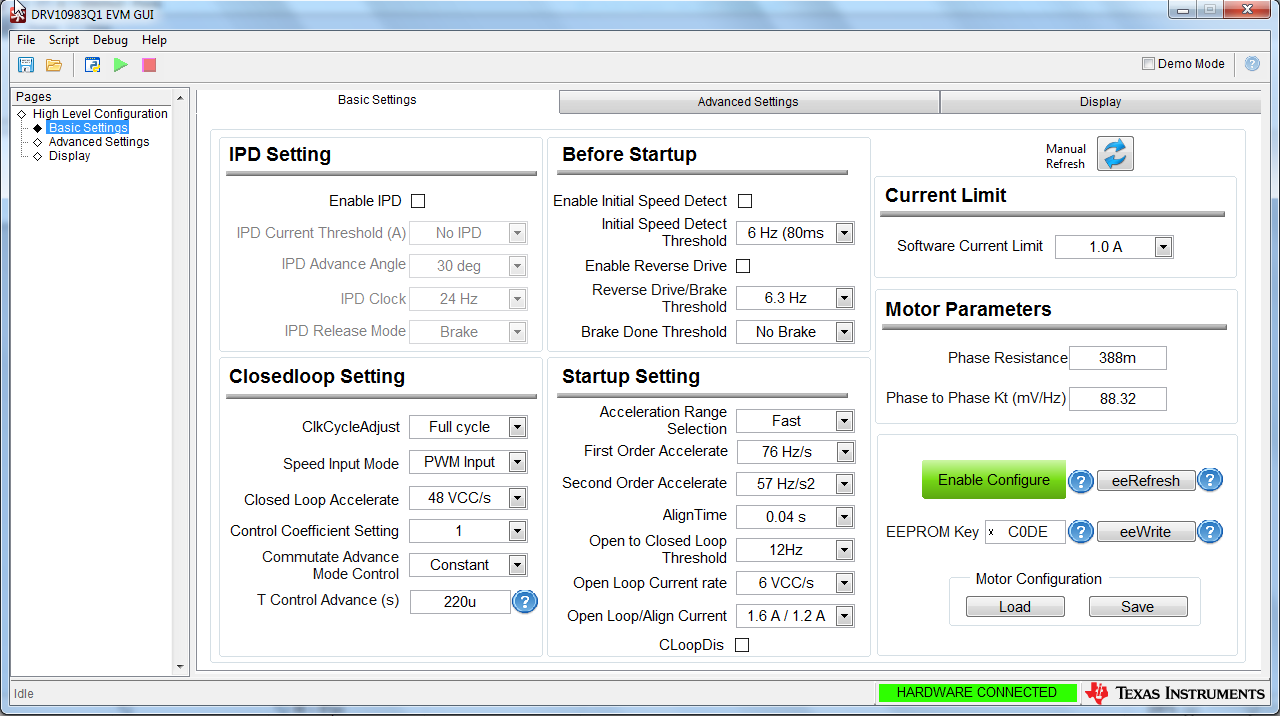

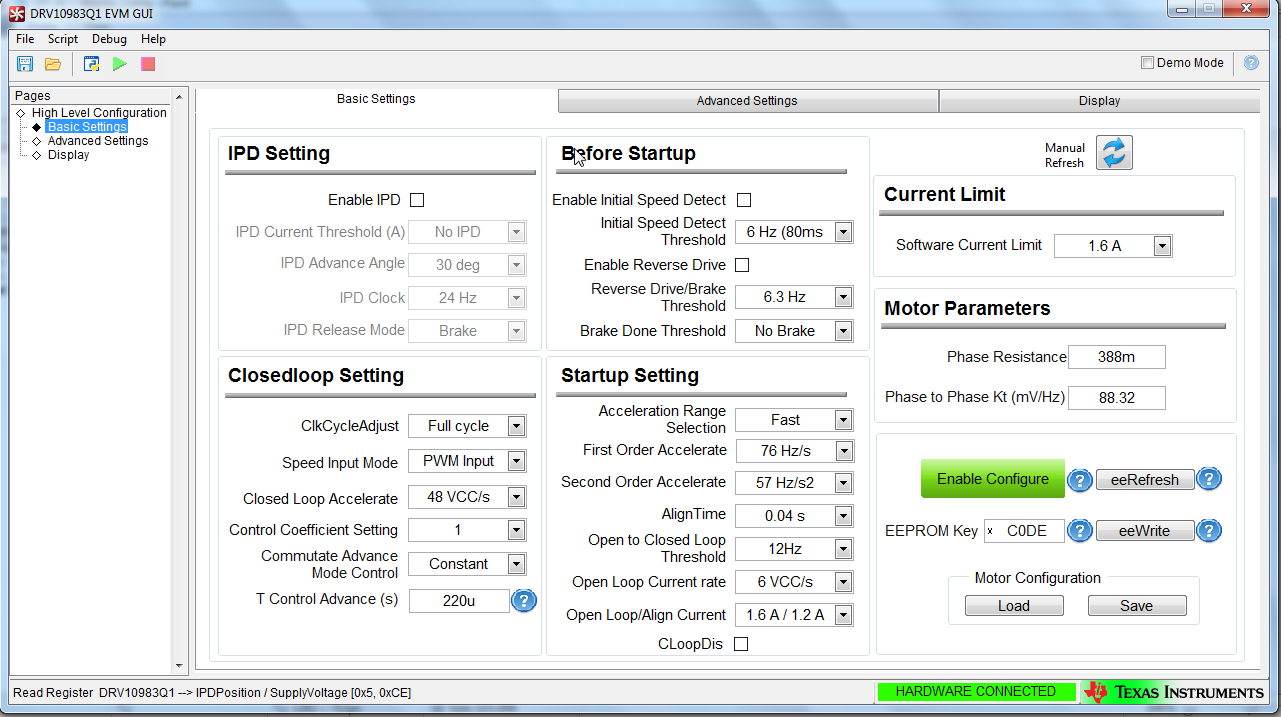

I'm evaluating DRV10983Q1-EVM to spin a 24V 3-phase BLDC motor(model No: 57BLF03 - hyperlinked) with 8 poles. Following are key parameters I set in the GUI of the EVM software:

- Phase resistance - 174.6 mOhm. This value is half of the resistance between U and V phase of the BLDC I'm using.

- Phase to Phase Kt - 73.6 mV/Hz . I calculated this value using the formula : Motor velocity constant = (VCC/Maximum motor speed(no load)) . VCC= 24V , Maximum motor speed = Max. RPM/ (60/No. of pole pairs) = 5000/(60/4) = 333.33. Now Kt = 24/333.33 = 72 mV/Hz. Closest value is 73.6 in the GUI of 10983Q1EVM

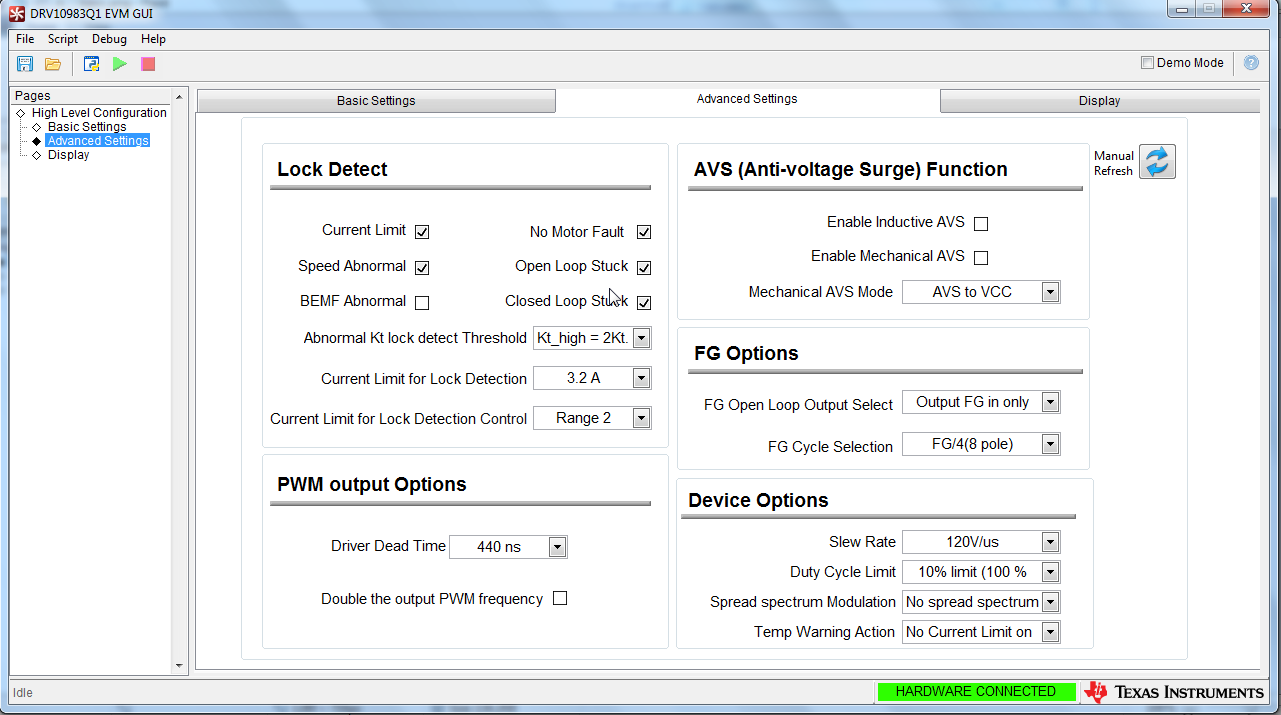

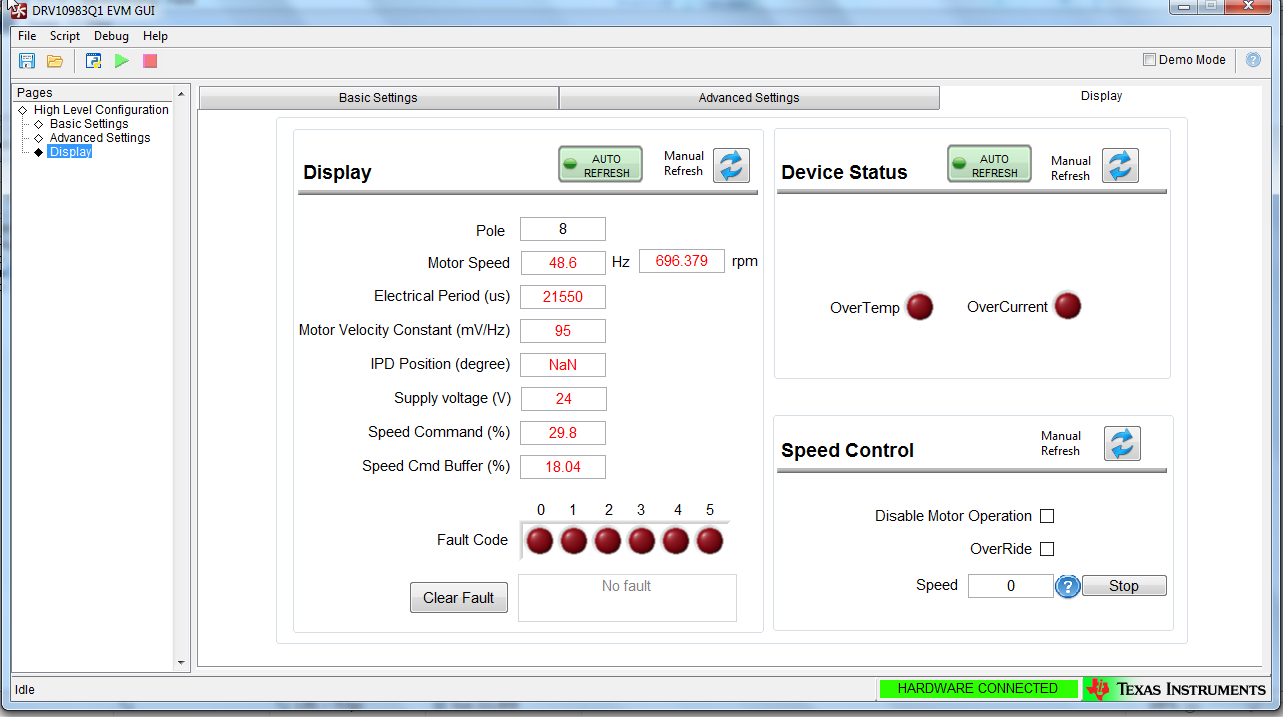

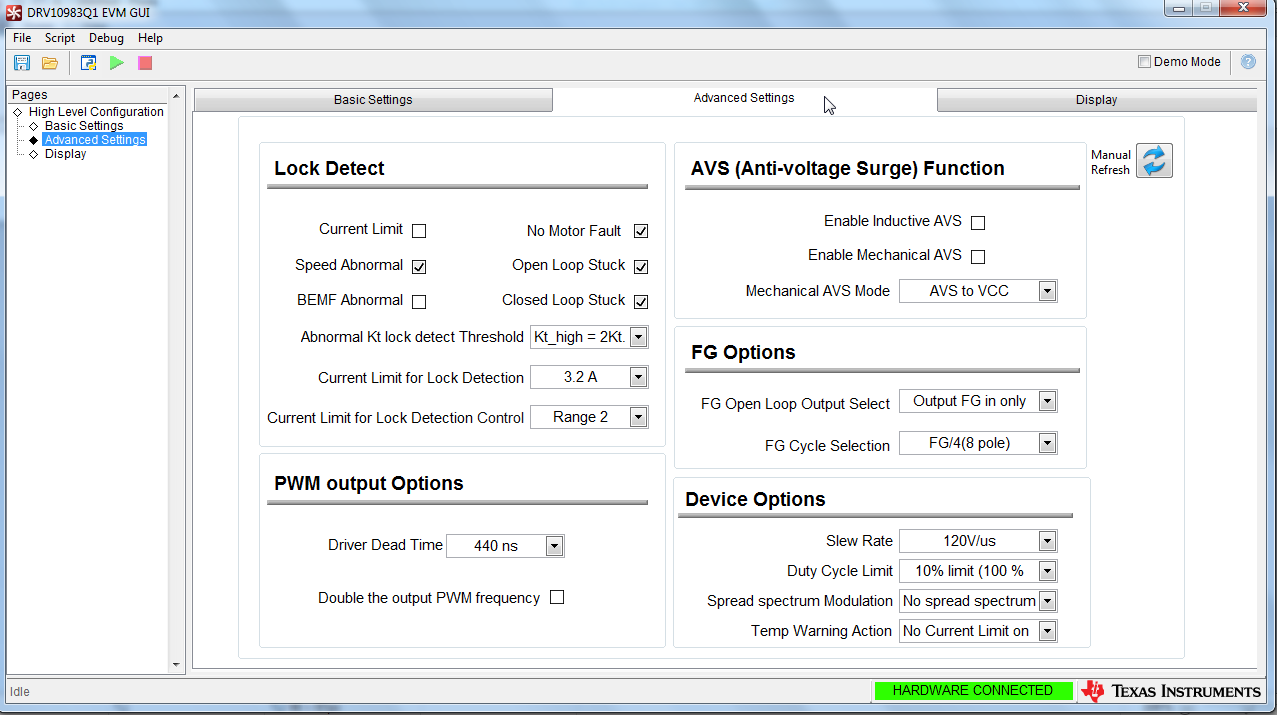

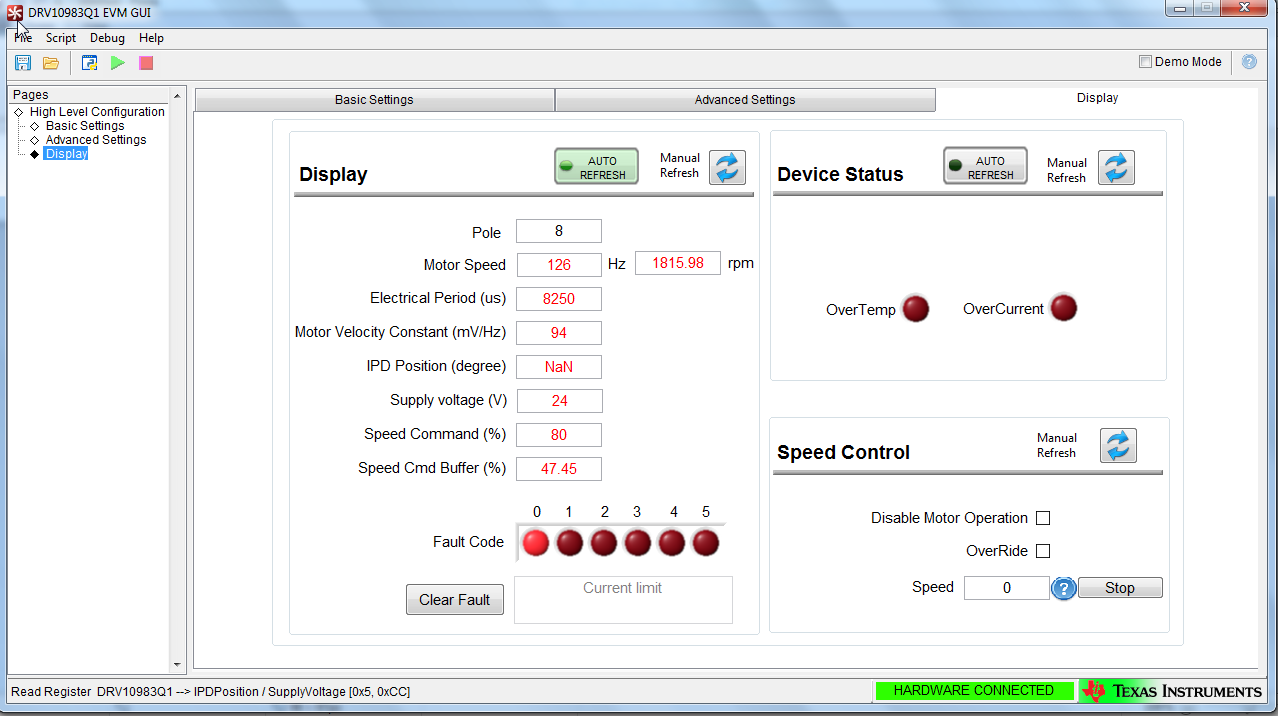

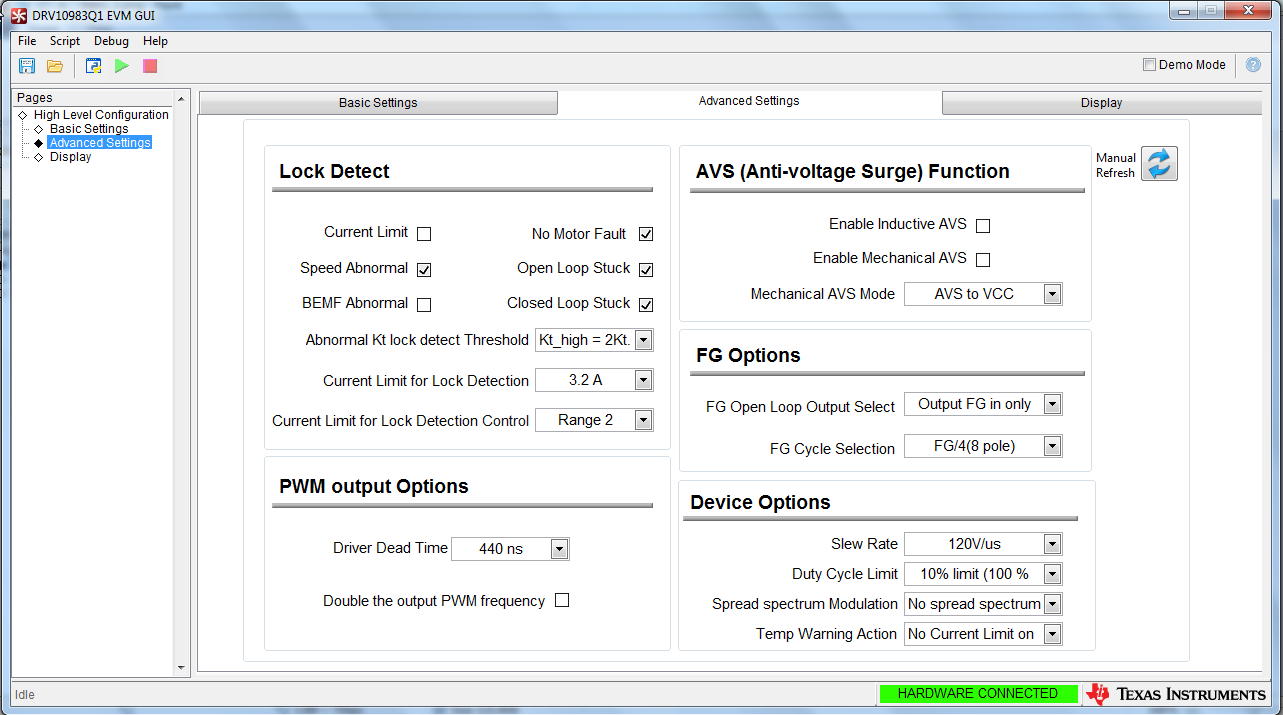

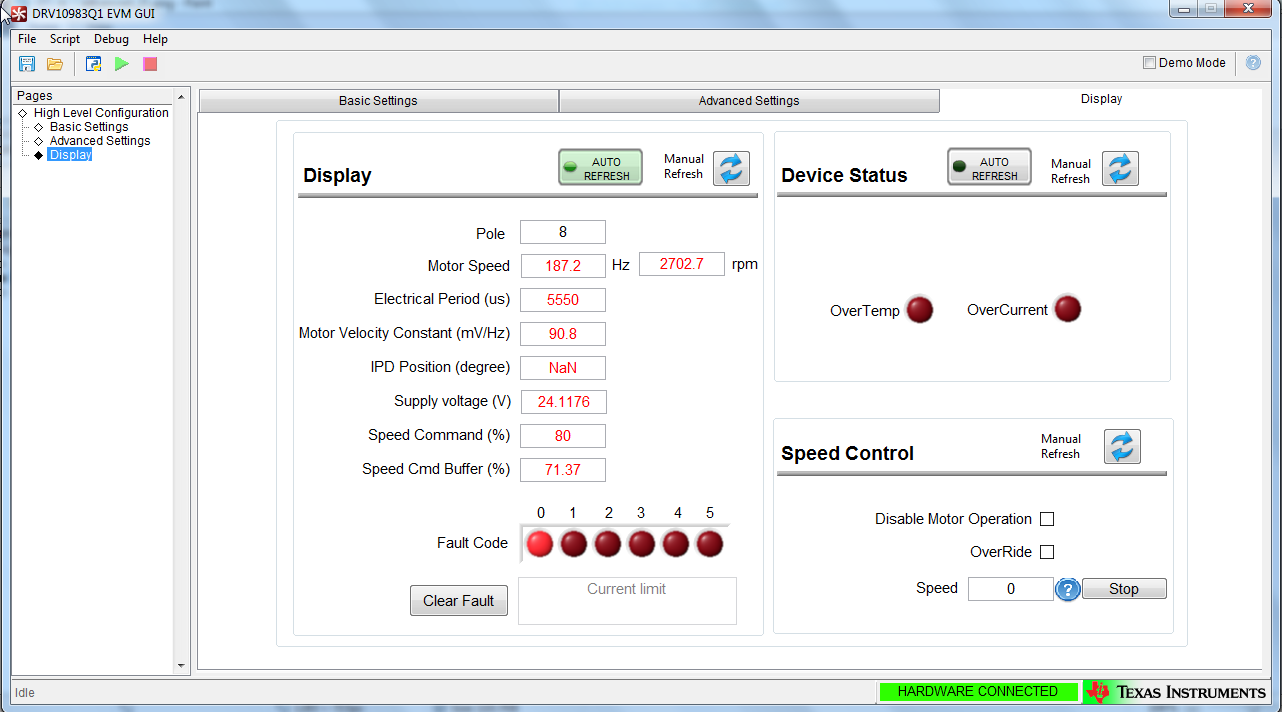

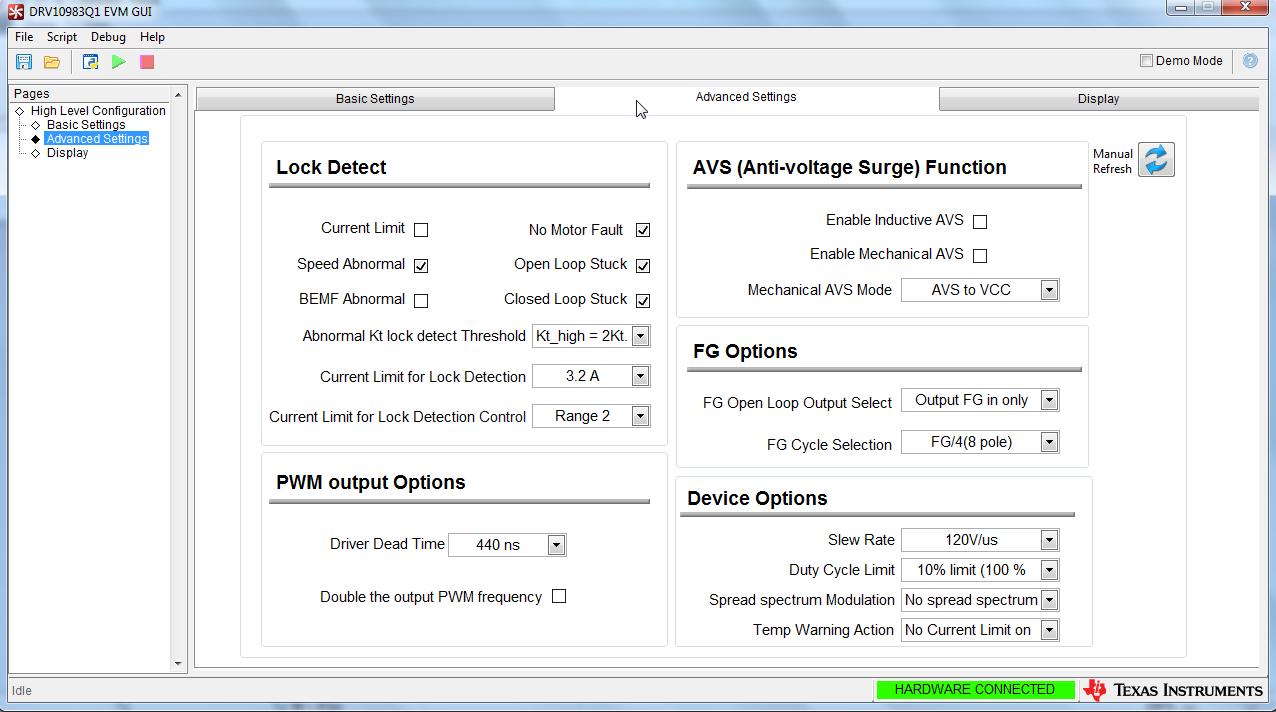

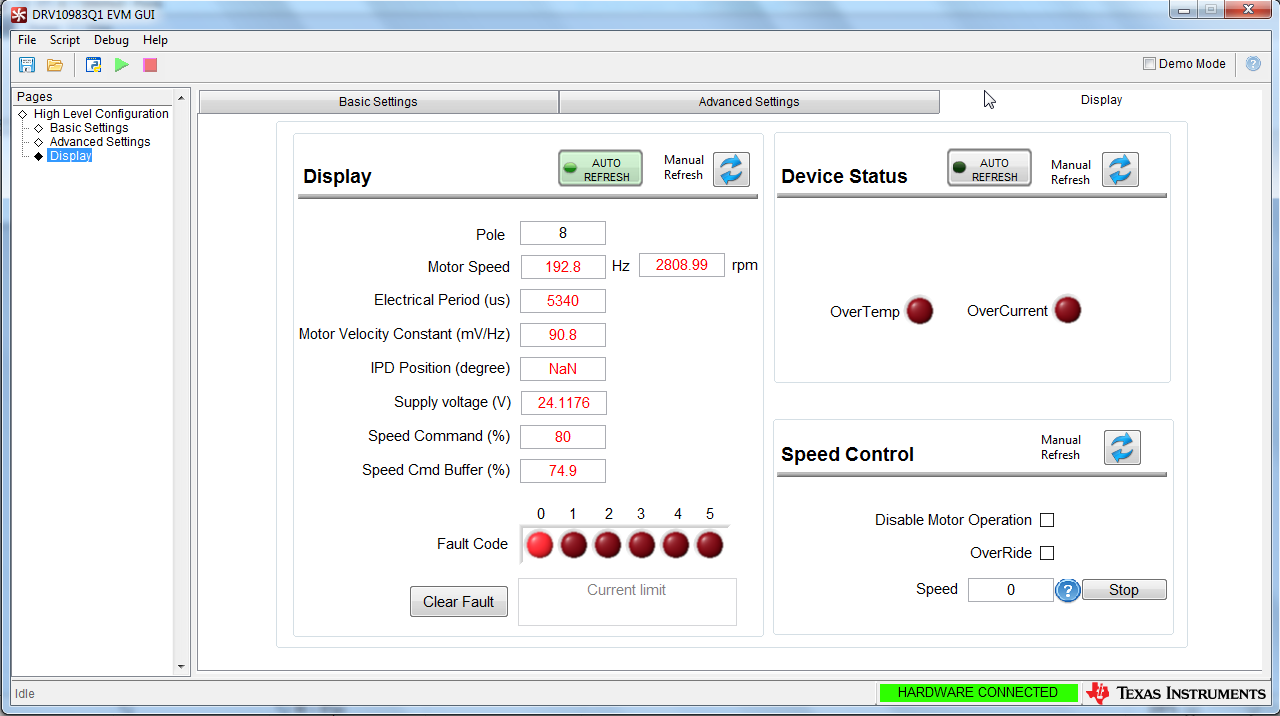

Following are the screenshots of the DRV10983Q1 EVM GUI

These are the screenshots when I'm trying to run the motor with PWM at 30% dutycycle from my Beaglebone. As you can see in the Display tab that speed CMD buffer is not able to reach Speed Command (if my understanding is correct, motor is running at 30% duty cycle when the Speed cmd buffer is at 30%.) If I increase my PWM dutycycle to 40 or 50 or 100 , Speed cmd buffer doesn't change and the motor speed remains unchanged. When I increase the software current limit to 3.0A or disable it and start the motor, it stops after few degrees of rotation due to the Fault code- 0 i.e current limit whereas the maximum current drawn from the power supply never exceeds 0.3A. The current limit is set to 2A on the power supply which the motor never crossed.

Below is an image of the oscilloscope and power supply. The frequency out from the FG test point on the 10983Q1EVM is 7.088Hz(in yellow) and the input pwm frequency in Blue is 2000Hz and duty cycle is 30%.

Kindly suggest what needs to be done to get the motor running at higher duty cycles i.e higher RPMs. Ultimately what I want to do is run PID loops on my BLDC motor with quadrature encoder which will require the motor to operate at different duty cycles ranging from(10-75) and requires fast response to accelerate the motor.