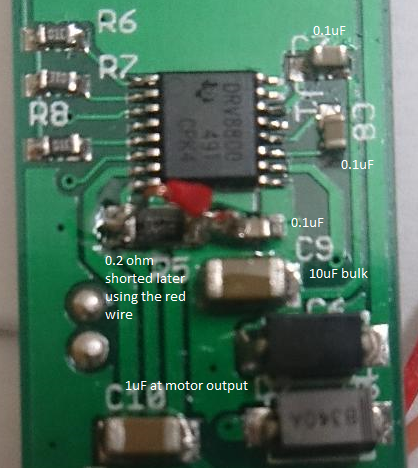

I've designed a board using DRV8800 to drive a small DC brushed motor. I first tested my circuit on a prototype board and when it seemed to work fine for the entire range of voltage that I'm going to support (8V to 24V), I got some PCBs fabricated based on the recommended layout. The only difference between the prototype and the PCB design was that I had shorted the RSENSE to GND in the prototype version but decided to use a 0.2ohm RSENSE instead for the PCB.

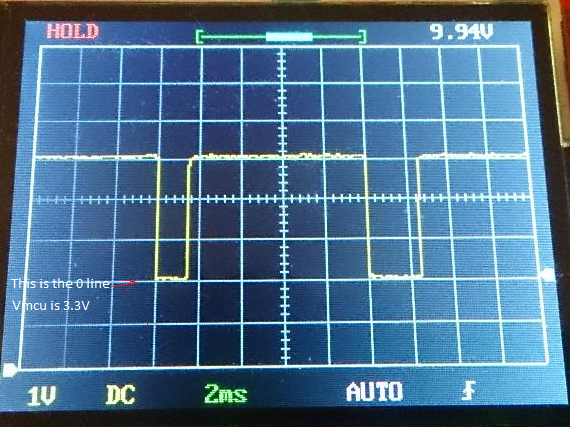

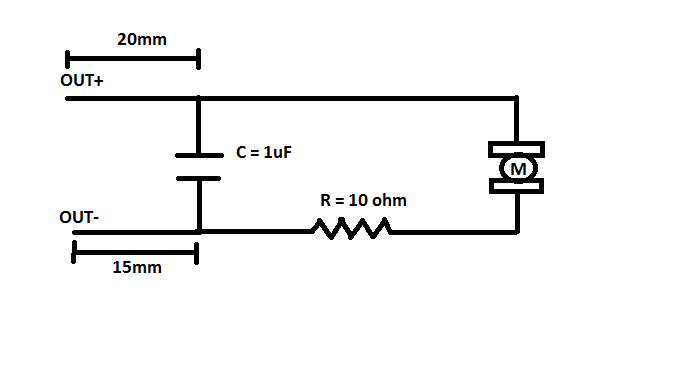

The problem I'm running into is that on PCB everything works fine up until VBB is about 15V and then it starts hitting the FAULT condition. I was able to marginally extend it to about 17.5V by shorting out the RSENSE on the PCB as well. So, essentially making it the same as the prototype and the VTRIP reads 0V. The scope reading of nFAULT shows variable downtime of about 1.5ms to 2.5ms. As another experiment, I connected a 10 ohm resistor in series with motor (R = 15 ohms) and I could get VBB to further a little more to about 18V before faulting.

I'm really stumped now that I've got several boards manufactured as well. What am I doing wrong?

I'm attaching the VOUT (with and without motor connected) and nFAULT scope output as well as the picture of the relevant section of the PCB for your reference. The board was hand soldered by me so please excuse my soldering skills.