Good morning,

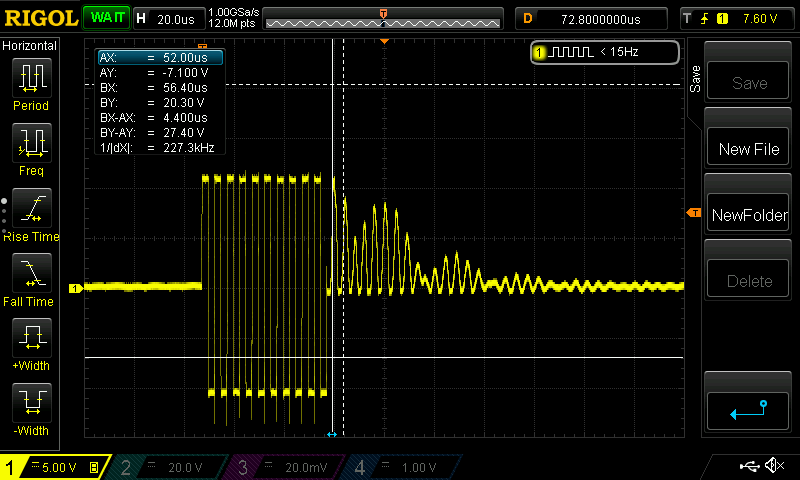

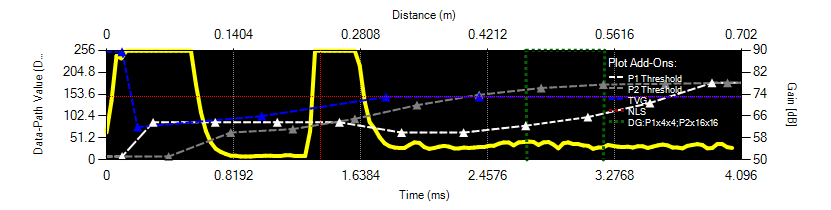

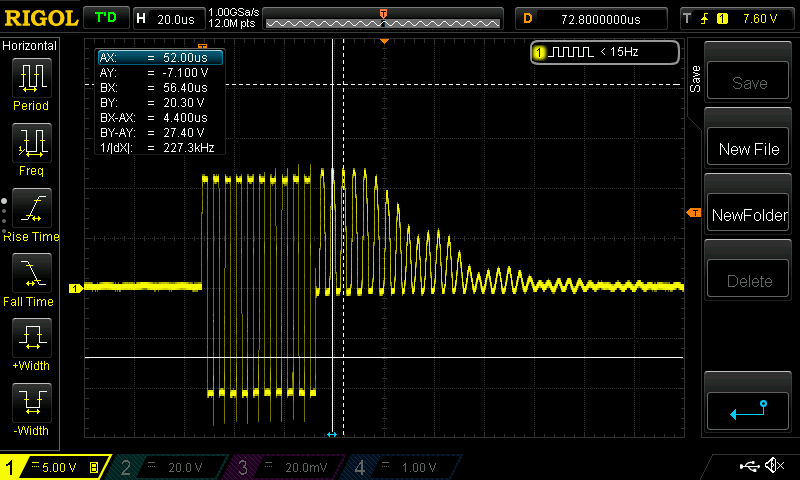

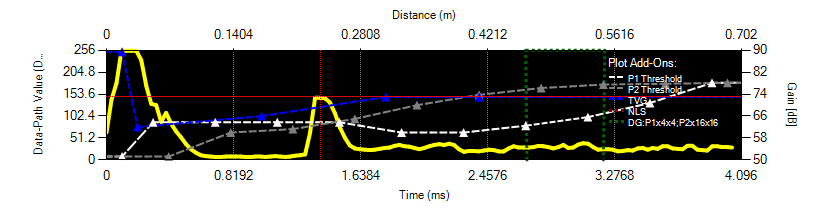

I'm developing an ultrasonic application with PGA460.

Using this component in monostatic configuration, it is recommended by TI experts to use an external motor driver to control the transducer.

At the moment TI suggest to use DRV8870, but in my application we are outside the specs, because I need to drive the transducer with a PWM of around 220kHz.

Do you have a part number with these mandatory characteristics:

1) PWM frequency: 220kHz or more

2) separate inputs to control the full bridge (like DRV8870)

It will be useful also to have:

1) shutdown pin or

2) low power device

Waiting for a kindly answer, I wish you a nice day

Best regards

Alessandro