Good day!

We are developing a high pressure laboratory pump, drived by DRV8711 and external MOSFETS (we selected SUD50N04-8m8P MOSFETS). The motor is POWERMAX II p22nrxc-lnn-ns-02 (According to datasheet, rated current 3.1A per winding, winding resistanse 1.56Ohm, winding inductivity 3.9 mH). Supply voltage is 24V.

Current sensing resistors is 0.05Ohm, and there are 100Ohm series resistors in low side gate nets, according to datasheet.

I am facing a problem with torque of motor - when I am rising current, motor starts to overheat, but torque is not increased, and is not enough.

I am not familliar with theory of stepper motors, and tuning of driver is not clear for me. Could you, please, help me with tuning?

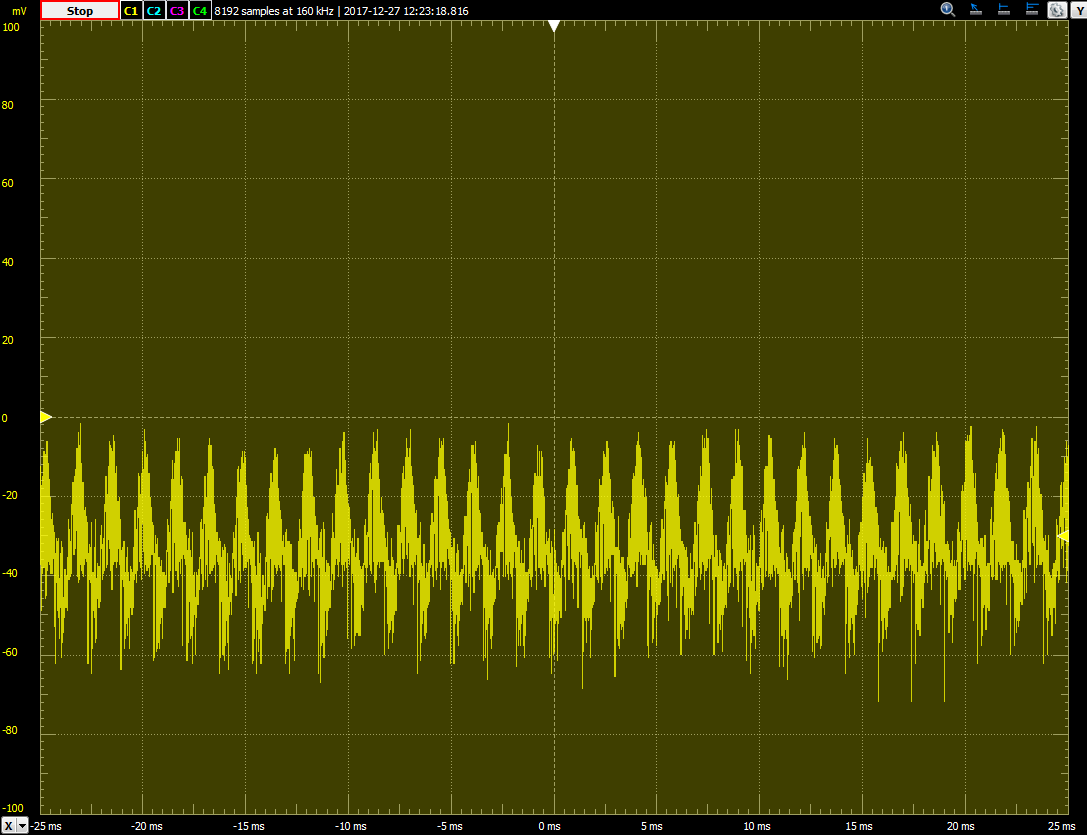

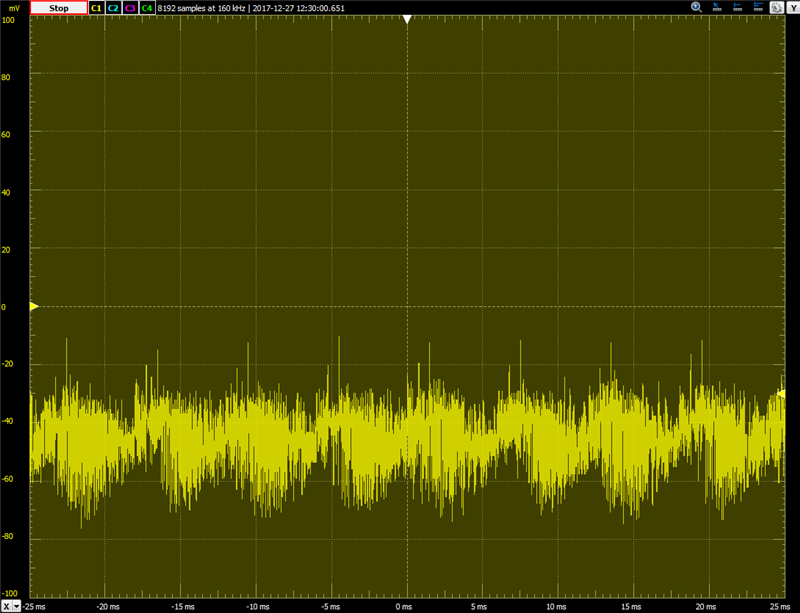

One thing is fery confusing for me - I do not see any sinusoidal signal on my scope on current sensing resistors.

Schematics are attached.