Support Path: /Product/Development and troubleshooting/Find key information on a device/

Hello,

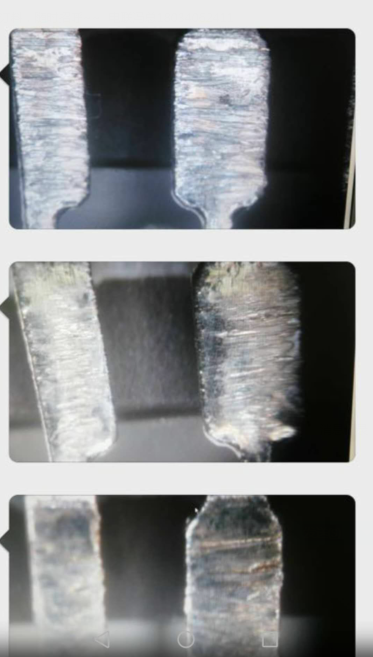

Our customer said that there are many wear scar on the parts' suface.They want to konw what cause of the wear scar.Can you help me explain the reson?

Thank you.

The following picture is observed under the magnifier.