Other Parts Discussed in Thread: DRV8301

Hello everyone,

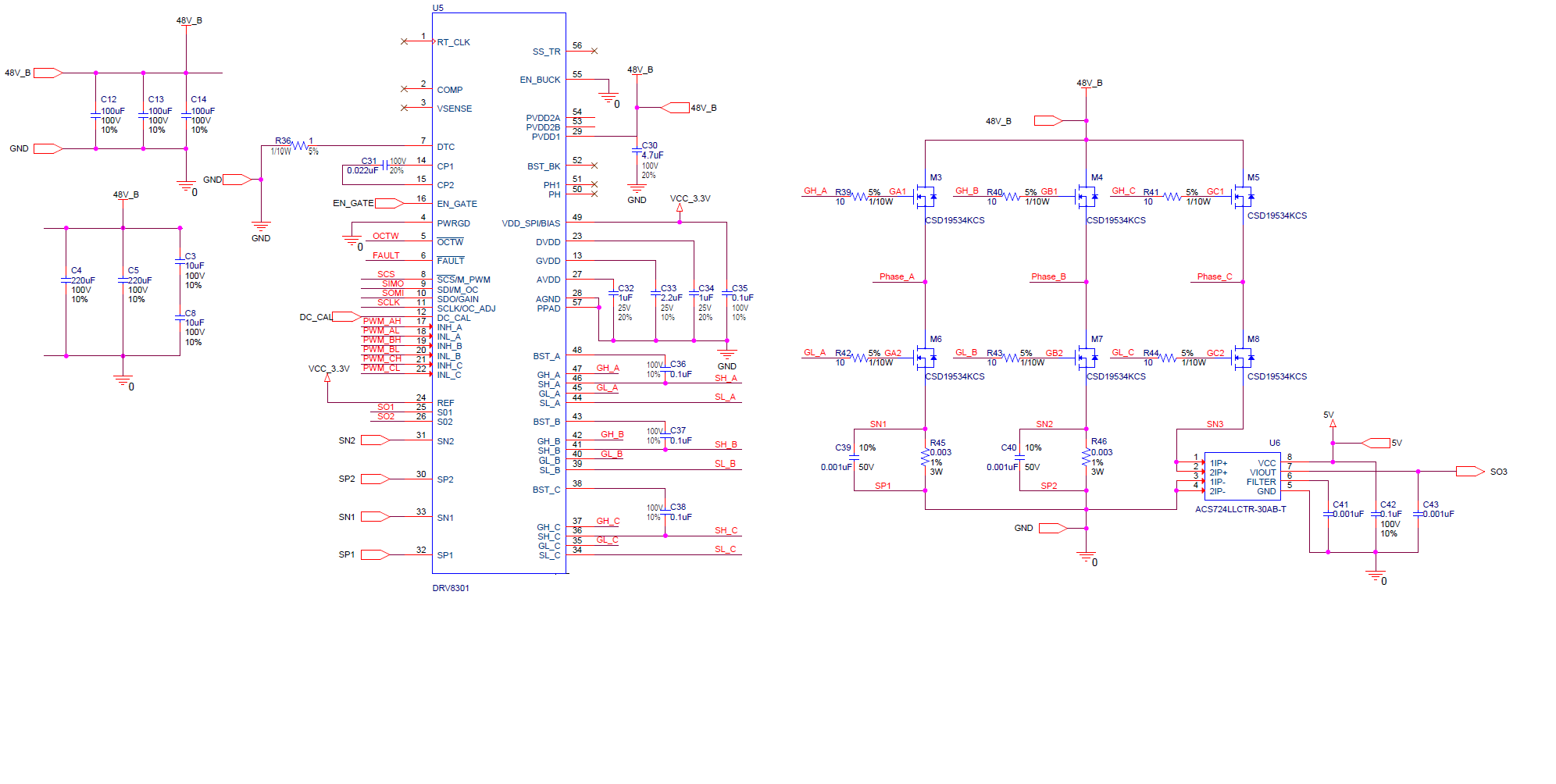

I am using the DRV8301 on a custom board to run a 48V 1000kW BLDC motor. We are trying to use 6-step commutation with a PWM frequency of 20kHz. We are 100% sure we have the correct commutation sequence because the motor came with a unidirectional (we are designing new controller for bidirectional control) motor driver and we measured the voltage wave forms for the Halls and phases. I am new to motor control but have done tons of research about sensorless and hall sensor based trapezoidal motor control for BLDC. Our first goal was to get the motor turning using open loop control before we moved on the a closed loop control via Hall sensor inputs. The way we decided to try and do this was to set the electrical frequency for the phases to give us a mechanical speed of approximately 2 revolutions per second. We are running a continuous loop to step through the commutations in one direction. We start the commutations with a 10% duty cycle and an input voltage of 48V on the DC bus.  We are not locking the motor to two phases as would be done in some sensorless techniques at start up before commutation. We then begin to slowly increase the duty cycle by 10% increments, with the thought being that the mechanical revolution we are trying to obtain is slow enough that the rotor will have time follow the rotating stator flux. However, as soon as we try to start the motor at a low duty cycle, the motor screeches (which I assume is from the rotor not being able to get to the excited phase fast enough). Then the DRV8301 FAULT pin indicates a fault. The DRV8301 will not come out of the fault even on a power cycle with the motor disconnected. The motor has 11 pole pairs and has 120 degree Hall sensors, resulting in a commutation change at about every 5.5 degrees. We believe that the DRV8301 is getting damaged but don't know what is actually causing the damage. We assumed that if the motor did not move with the commutations, we would be able to slightly turn it by hand to get it to engage since we are trying to turn the motor at a low RPM, but before we can even touch the motor the DRV8301 gets damaged. Any help or advice would be appreciated. I am attaching the schematic, but if any more info is needed just ask.

We are not locking the motor to two phases as would be done in some sensorless techniques at start up before commutation. We then begin to slowly increase the duty cycle by 10% increments, with the thought being that the mechanical revolution we are trying to obtain is slow enough that the rotor will have time follow the rotating stator flux. However, as soon as we try to start the motor at a low duty cycle, the motor screeches (which I assume is from the rotor not being able to get to the excited phase fast enough). Then the DRV8301 FAULT pin indicates a fault. The DRV8301 will not come out of the fault even on a power cycle with the motor disconnected. The motor has 11 pole pairs and has 120 degree Hall sensors, resulting in a commutation change at about every 5.5 degrees. We believe that the DRV8301 is getting damaged but don't know what is actually causing the damage. We assumed that if the motor did not move with the commutations, we would be able to slightly turn it by hand to get it to engage since we are trying to turn the motor at a low RPM, but before we can even touch the motor the DRV8301 gets damaged. Any help or advice would be appreciated. I am attaching the schematic, but if any more info is needed just ask.

Thank you,

Brandon