Hi

We build for our students a demo board with 4 DRV8412. We build up 47 units but on 16 at least one driver (in most cases) one of two outputs doesn't work.

Sometimes only one is not working but they are different (not always the same output). On some of them all are not working.

We use the Dual full bridges mode (one PWM input each full bridge with complementary PWM on second half bridge) with cycle-by-cycle current limit.

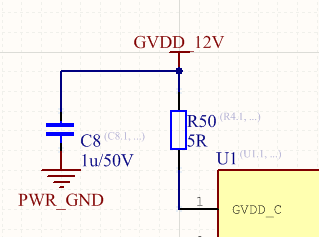

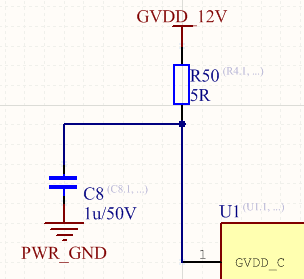

A PWM frequency between 1kHz to 10kHz. For that we select a 1uF bootstrap capacitor with one 3.3Ohm resistor.

We use the an additional inductance (100uH) at the output like on the demo board.

On some of the boards I soldered again the capacitors to make sure there is no issue with that.

One unit I could fix with that. But as I tried to solder the others to there was no success with only soldering.

I tested the outputs of one board with an external resistor to ground or VCC. And found that the upper transistor is not switching. The bootstrap voltage looks good (12V) the bootstrap diode was also working (tested with a multimeter between BST and GVDD)

What could damage the transistor in such a configuration? Do you have any advice how to find the error?

Kind regards

René