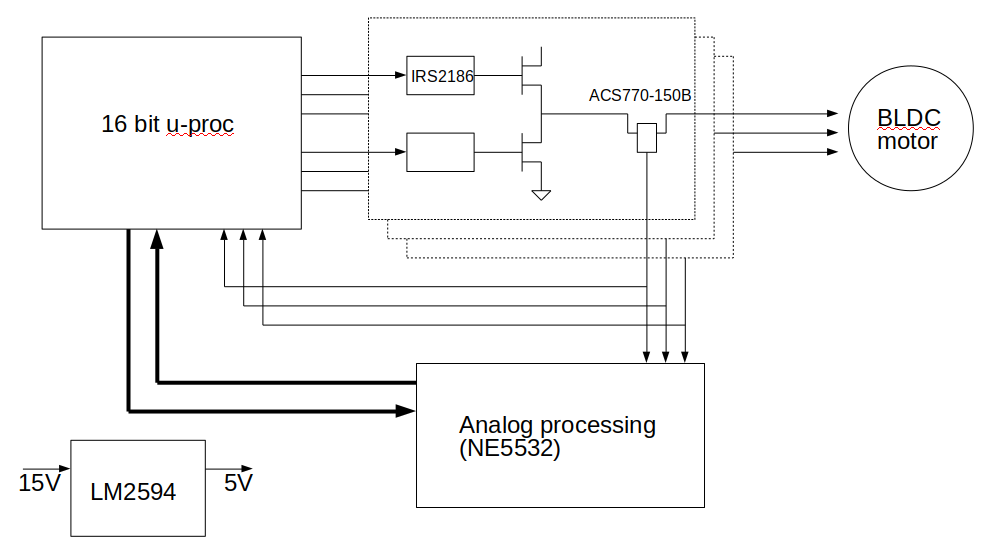

Just wanted to share my success building a system for sensorless detection of the rotor position of a bldc / pmsm motor. (I hope this is allowed). This with the rotor standing still and from power-up, so with no history present in the microcontroller.

I get the same 0-359 degrees electrical rotor position info as you would with a resolver. While the rotor position measurement is running it is possible to apply phase current for generating torque.

I posted two videos on youtube, channel bmp72 . In both videos the motor is only connected via the 3 phase wires....