Hello,

I'm a product developer and electrical engineer working with the DRV8871 in an existing circuit.

We're having a bug. Here's the background:

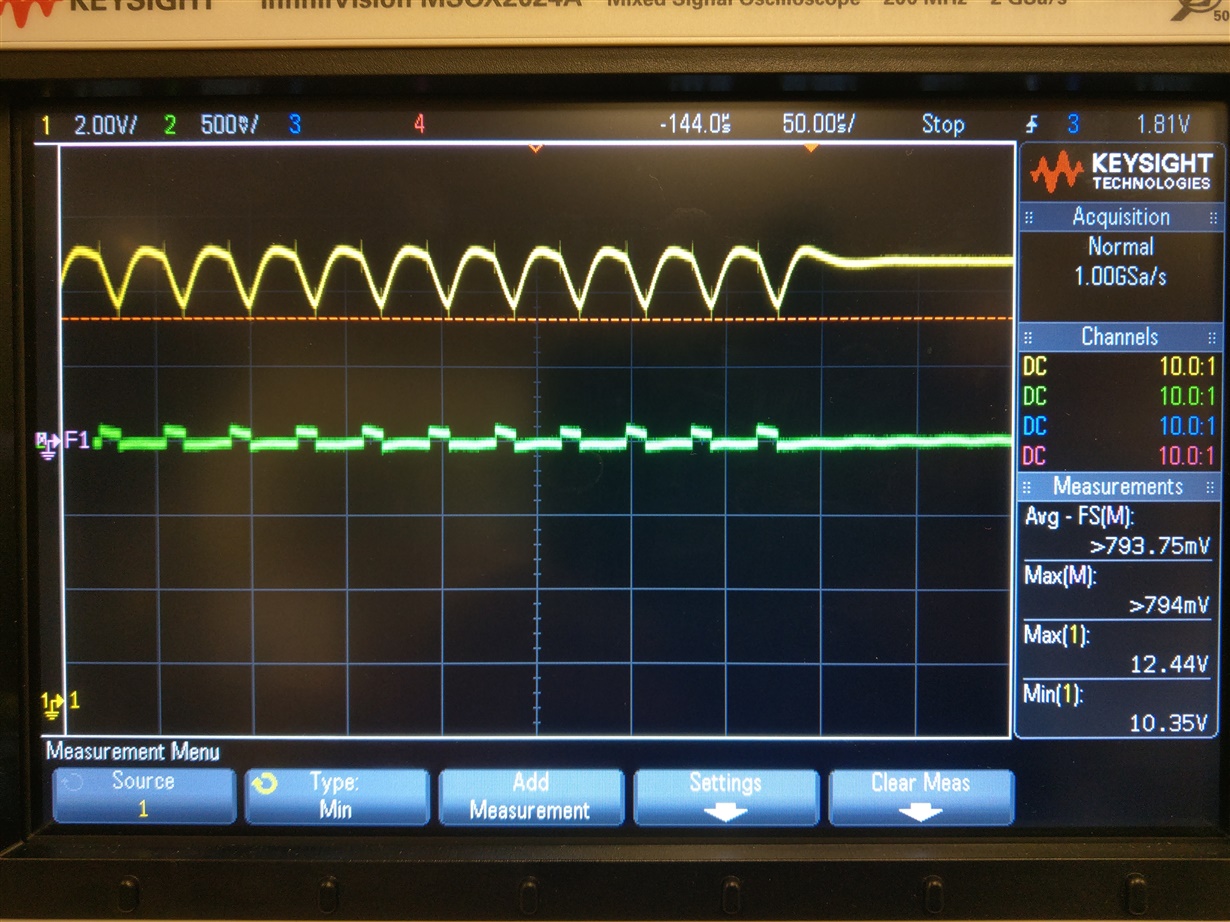

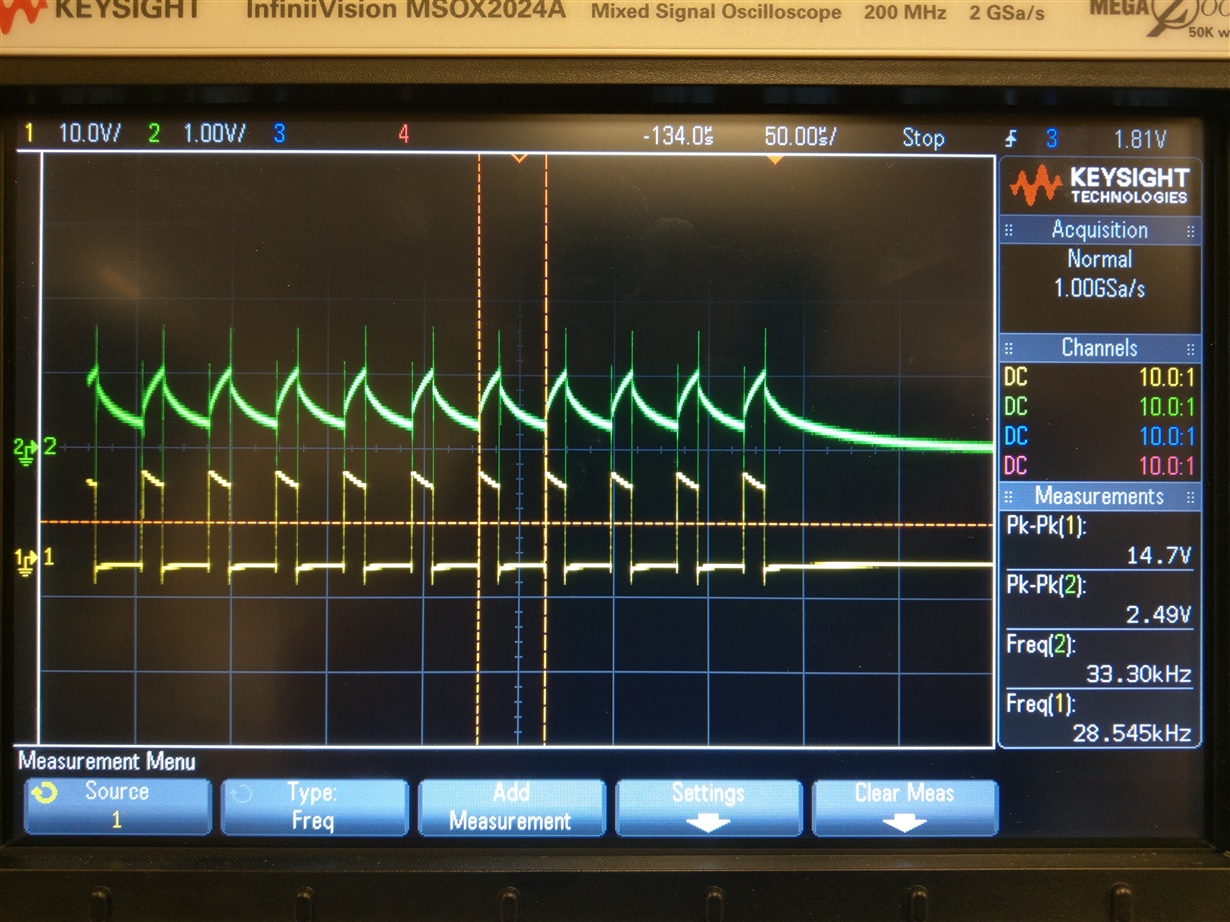

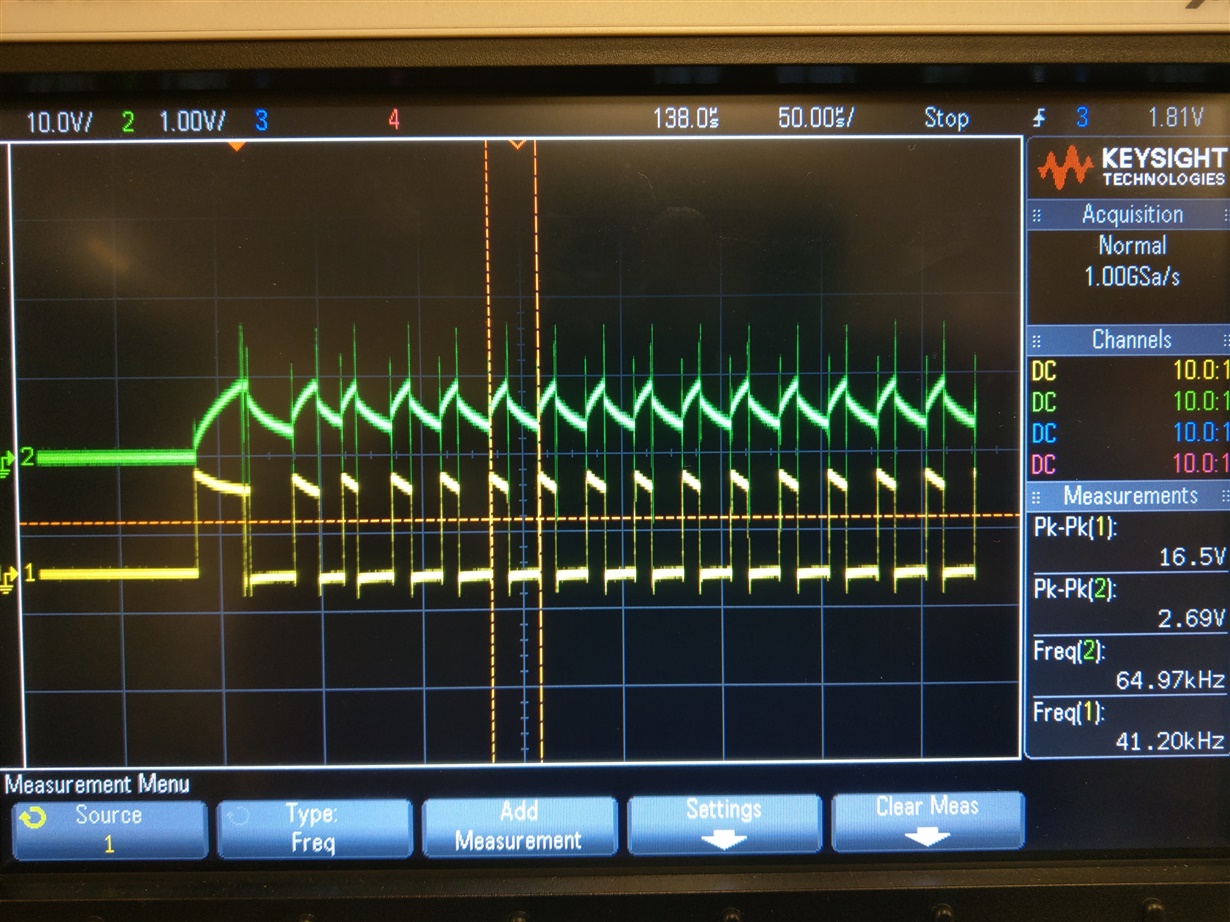

- The motor can successfully lift 15 pounds if a 100% duty cycle is used on IN1

- The motor stalls when trying to lift 20 pounds if a 100% duty cycle is used on IN1

- The motor can successfully lift 20 pounds if a 99% duty cycle is used on IN1

Fixes I have tried:

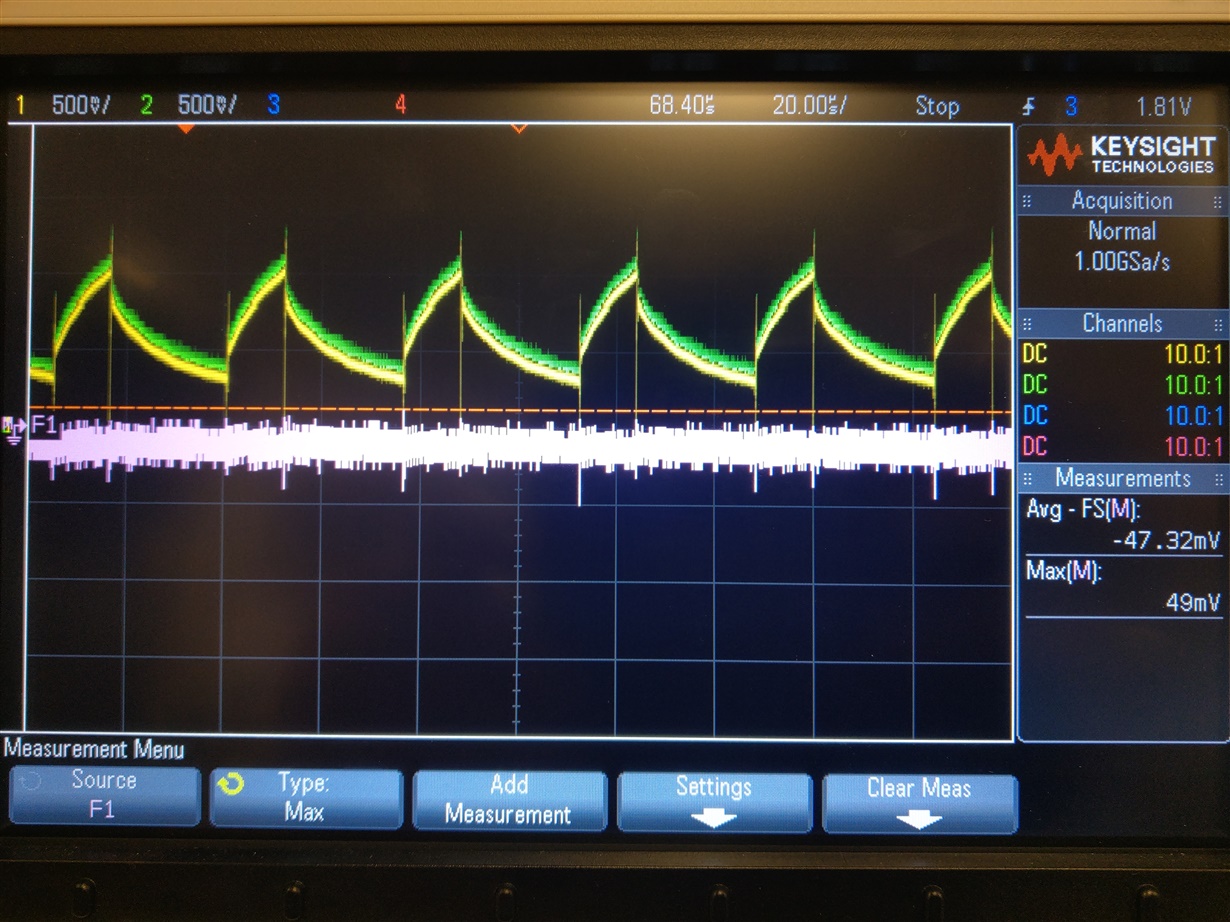

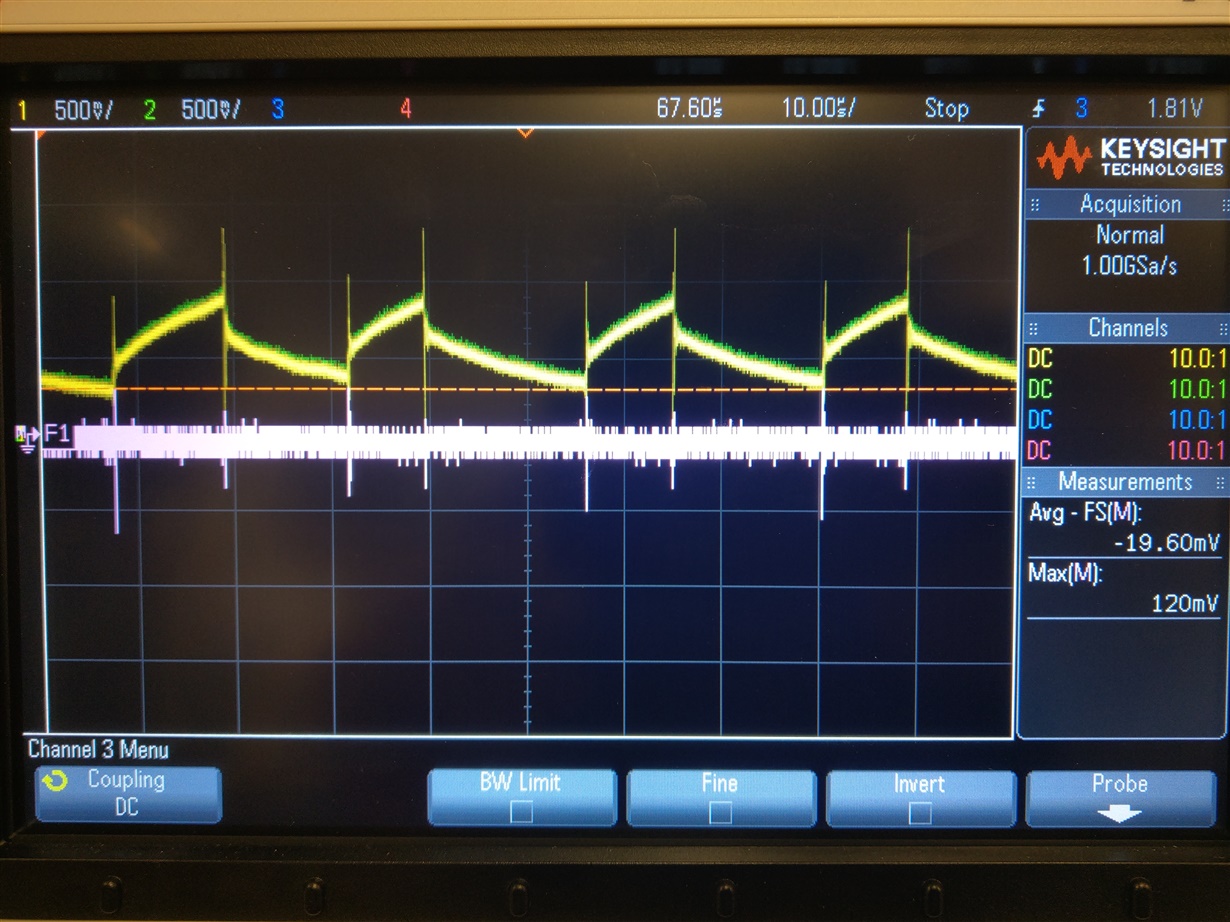

- We had the Current Limit resistor set to 34K, to limit to 2 Amps and received this issue. The value was then dropped to 27k, to allow for 2.3 Amps, which did not help. Then I dropped the value to 15k to disable current limiting, and this did not help either.

- I have shorted IN1 to ground, as the control method, and we get the same results. So this is not an issue with the control line inputs.

- I have also increased the bulk capacitance on the Vmotor line from 10uF and 0.1uF to 47uF and 0.1uF. Still I am receiving the same results.

- One time, randomly, everything worked fine and the motor could lift 20 pounds using 100% duty cycle input, but I have no idea why and haven't been able to replicate this.

- I also have a large fan blowing straight on the DRV8871 chip, so I dont believe temperature is the issue

So we are seeing this issue where the motor stalls on higher loads only when 100% duty cycle is used at the input. But it can lift the same weight if a 99% duty cycle is used.

We have seen this issue on multiple of our products, so I don't believe it is a one-time bug.

I can send a schematic privately, but it is very similar to the recommended setup in the datasheet. We have only added an inductor and 2 capacitors on the motor lines to reduce back EMF

Please let me know if you have any ideas of what might fix this,

Thank you, Mike