Other Parts Discussed in Thread: , DRV8872

Hello,

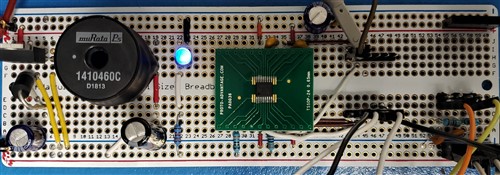

I am using the DRV8816 Motor Driver to control a 24V Brushed DC Motor (inside of a linear actuator). I am noticing issues with low side not being pulled low all the time.

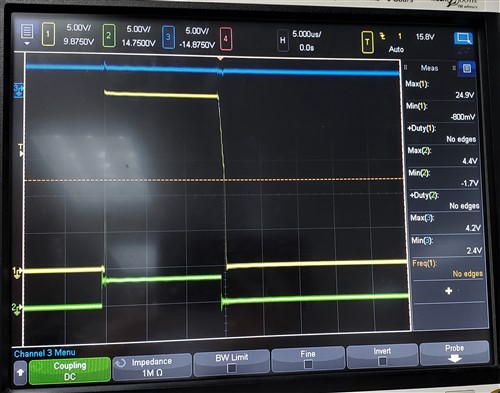

In the first case, I have both EN lines pulled HIGH (3.3V). I have IN1 LOW (GND) and IN2 HIGH (3.3V), so I expect OUT1 to be LOW (0V) and OUT2 to be HIGH (24V). However, I notice that OUT1 will pulse HIGH at times. See first picture and second picture for a zoomed in view of the pulse. OUT1 is yellow and OUT2 is green. The motor will still drive, but I am wondering why is this happening? And is there anything I can do to get rid of this effect?

As a followup, I also tried to PWM the inputs and the behavior is even more noticeable. Again I have both EN lines pulled HIGH (3.3V). In the first picture, I have IN1 LOW (GND) and IN2 being PWM (0V to 3.3V) at a 50% duty cycle and 10kHz frequency. You can see OUT2 is being PWMed as expected, but OUT1 is pulsing HIGH at the same time OUT2 goes HIGH. In the second picture, I have IN1 being PWM (0V to 3.3V) at a 50% duty cycle and 10kHz frequency and OUT2 LOW (GND). Again, OUT1 is being PWMed as expected, but OUT2 is pulsing HIGH. Additionally, if I increase the frequency of the PWM signal that seems to increase the period the time the outputs pulse high for.

Can anyone explain to me what is happening and how to solve this issues?