Other Parts Discussed in Thread: INA301, DRV8876

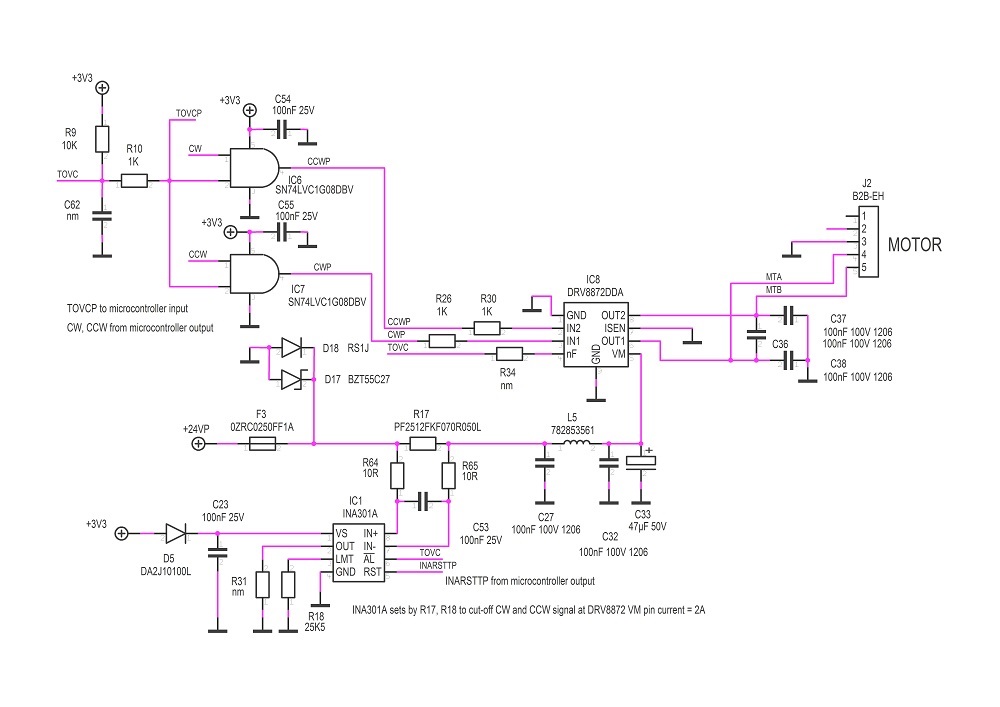

In my application I use an INA301A1 in transparent mode to limit motor current to about 2A in case of rotor lock, as the DRV8872 OVC limit has a too much large tollerance (3.7 to 6.4A).

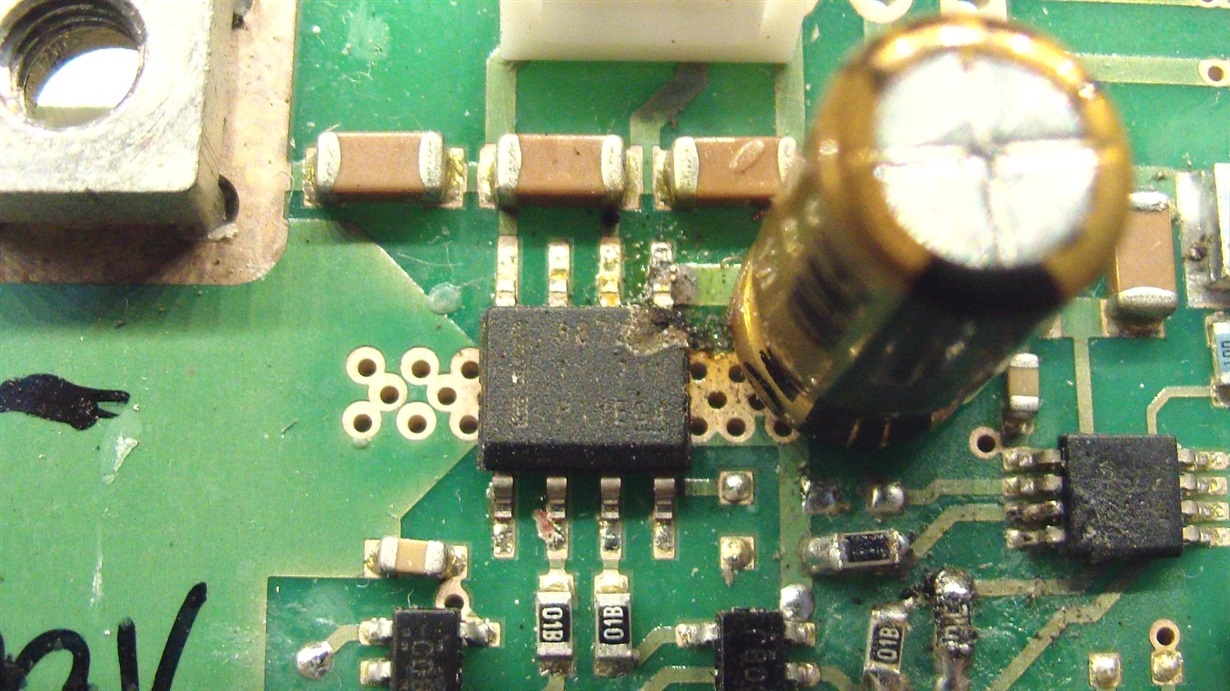

In a couple of cases I had the failure you can see in the attached photo: VM pin burned-out.

Power supply is 24 to 29V, ambient temp. 20..25°C, motor is simply turned on by 700..800 msec CW or CCW static signal every 2..5 seconds, no PWM used. What could be the reason for this kind of failure ?

Thank you in advance for your kind attention.

M.R.

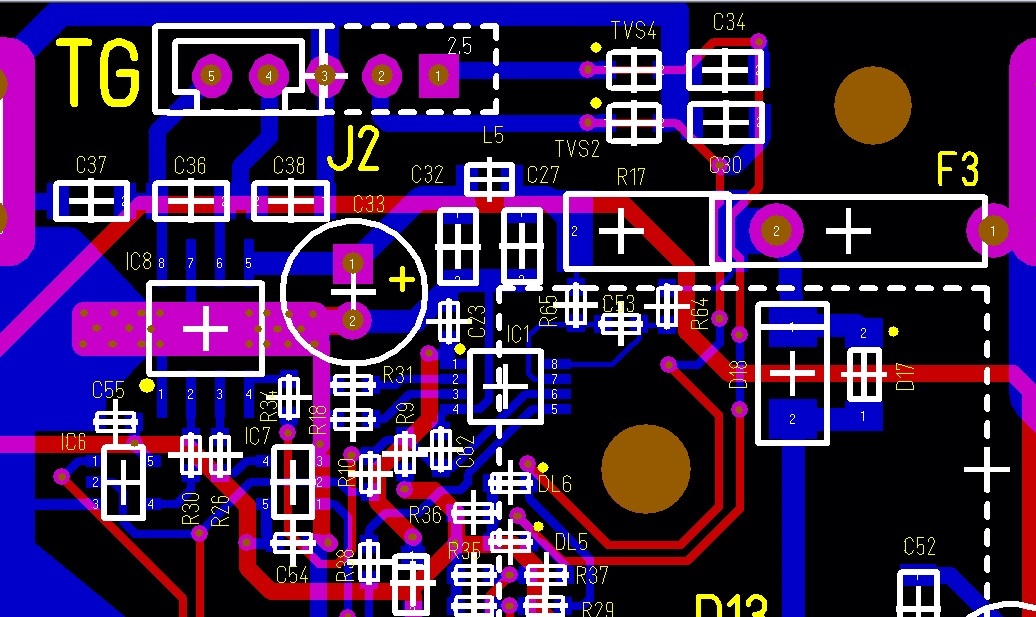

Here are also my pcb lay-out and electric diagram.