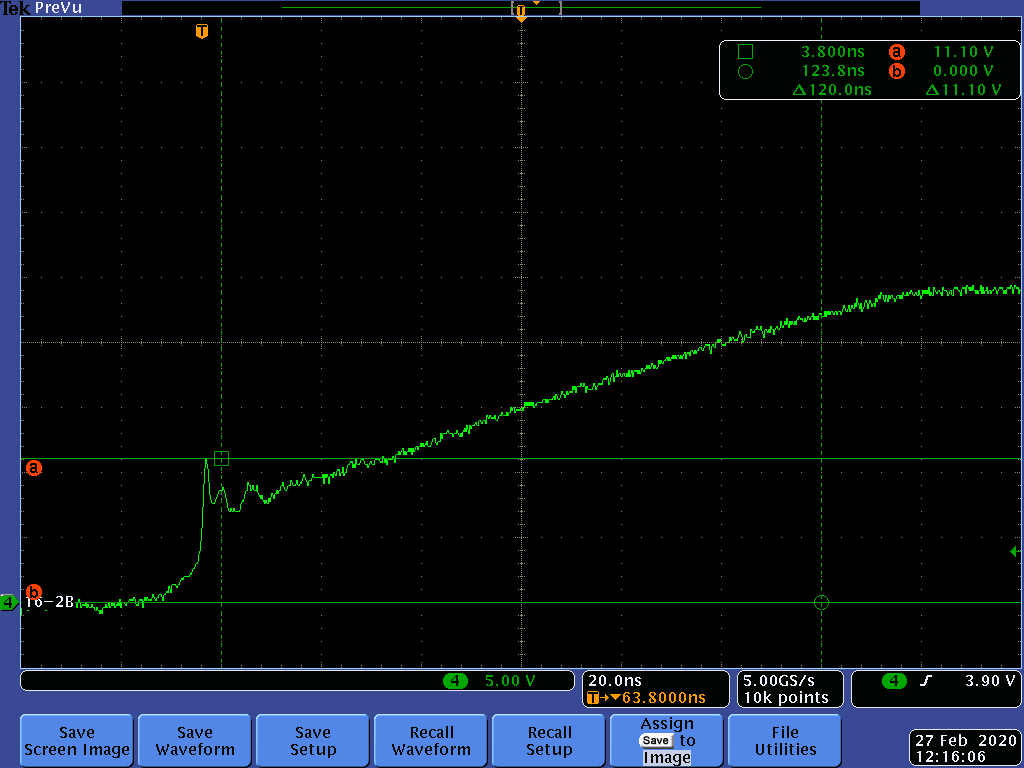

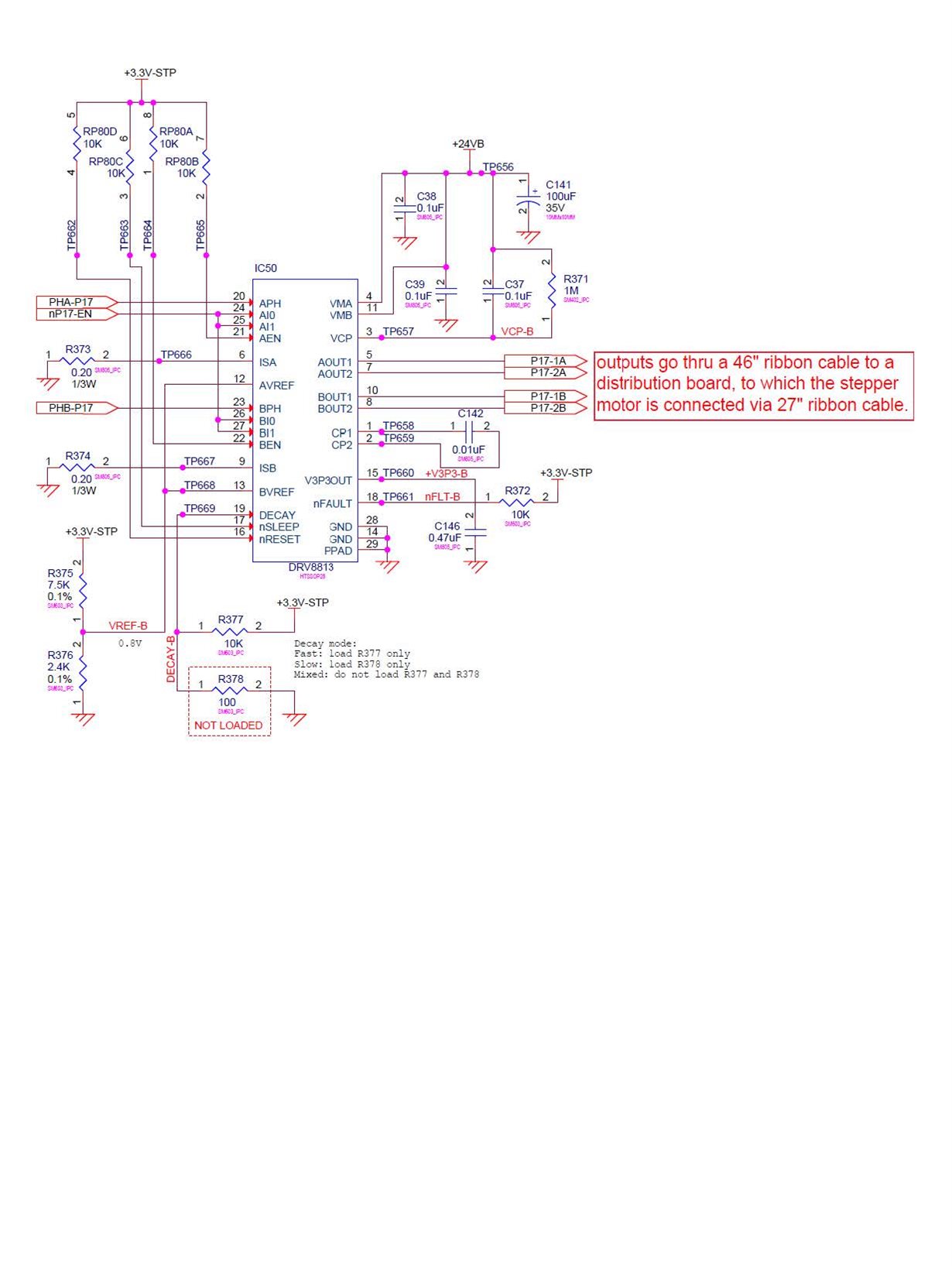

My design using three DRV8813's has a radiated emissions problem - the parts appear to emit a broad-band RF centered around 140 to 150 MHz, and raise the emitted RF noise floor across the spectrum by about 5 to 8 dB. When I force the DRV8813's into "sleep" mode, the emissions go away, indicating there is something active in the part causing this.

Do you have any recommendations for reducing/minimizing radiated emissions from this device?

thanks