Other Parts Discussed in Thread: , MSP-EXP430G2ET, INA194,

Good morning to all.

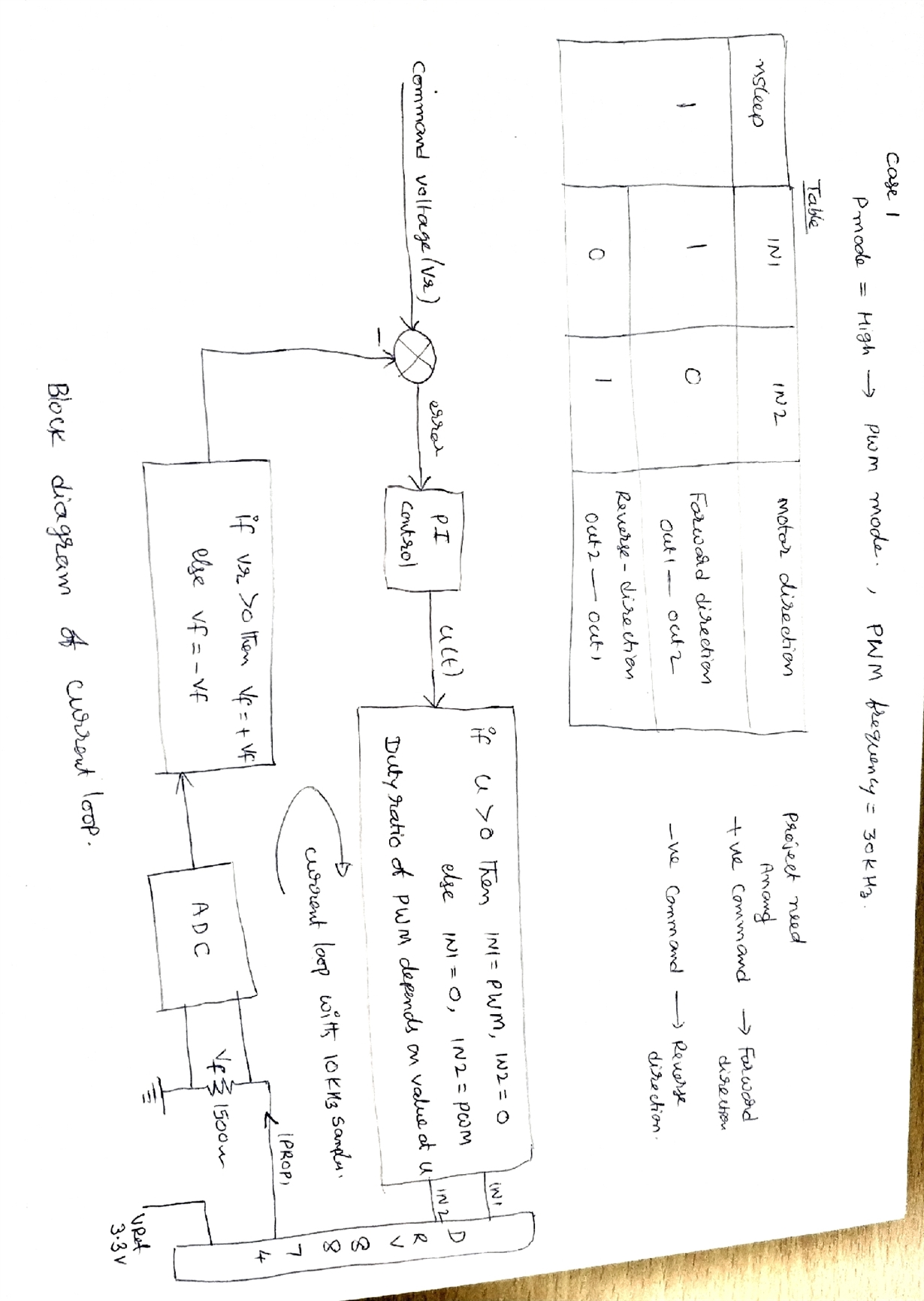

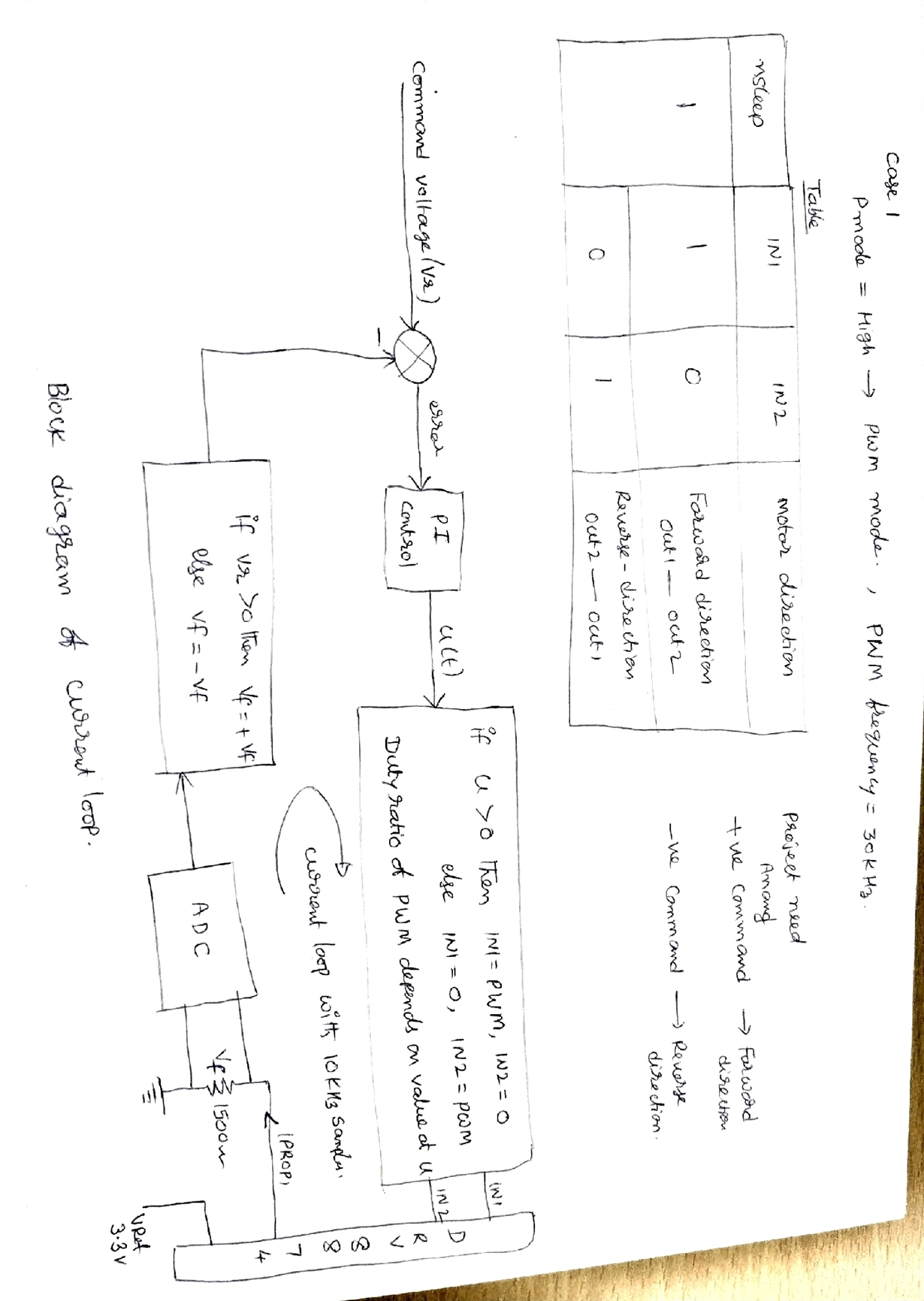

I would like develop one new application to a DC brushed motor using DRV8874 integrated current sensor IC. Main objective is to implement current loop / torque loop using current sense output voltage across RIRPOPi resistor. My application needs bidirection control with speed variation with PWM control. I need current value will be compared then error should pass through PI controller then PWM signal.

Please suggest to the following questions.

1) Is there any application note to meet my application?

2) For that application which control method is better PH/EN mode or PWM mode. what is the difference between these two modes.

3) Current sense direction is always positive, irrespective of forward direction or reverse direction.. How to use in current loop for implementing PI controller.

4) I designed values are : Rpropi= 1500 ohms, I TRip=4.835A, VADC requirement=3.3V, Vref:3.3V.