Hi Team,

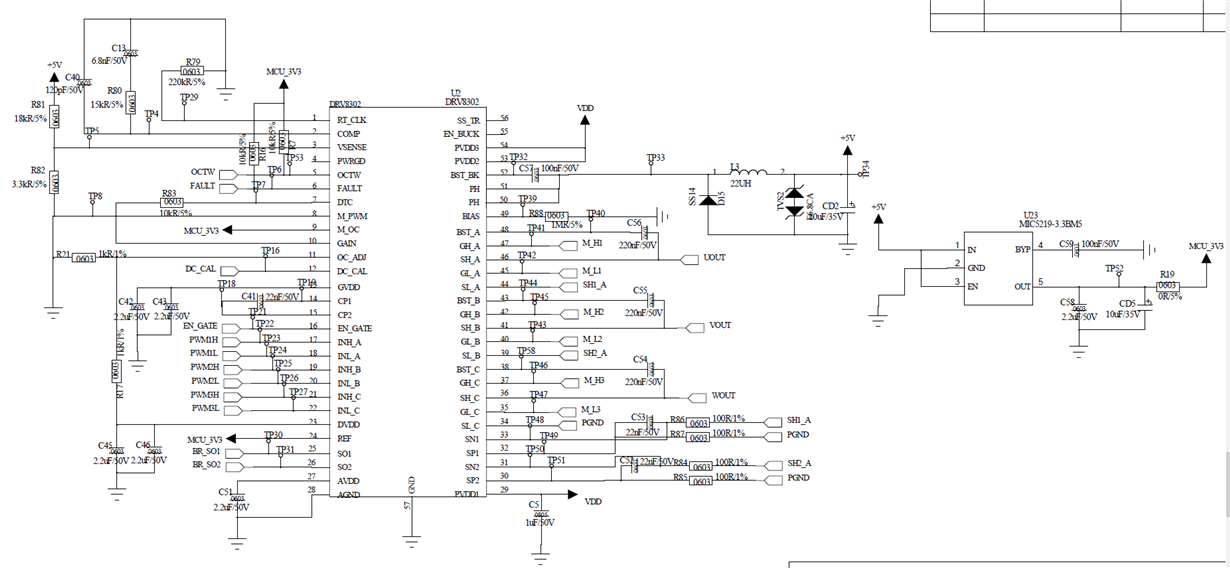

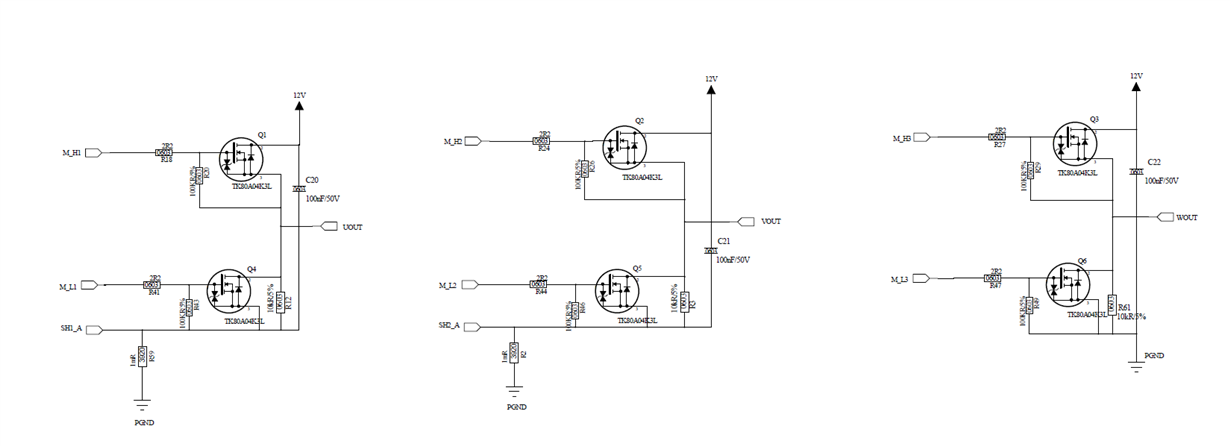

The customer refers to the overcurrent protection circuit connected to the DRV8302 Datasheet, but obviously feels wrong.

Adopt 1: 1 partial pressure (we use MOS tube R (on) = 3.6mΩ) current limit to 450A. In actual applications, such a large current is not reached, but an overcurrent error will still be reported. Is the customer understanding wrong? Can the overcurrent protection function be achieved by directly dividing the two resistors in practical applications?

Best Regards,

Annie