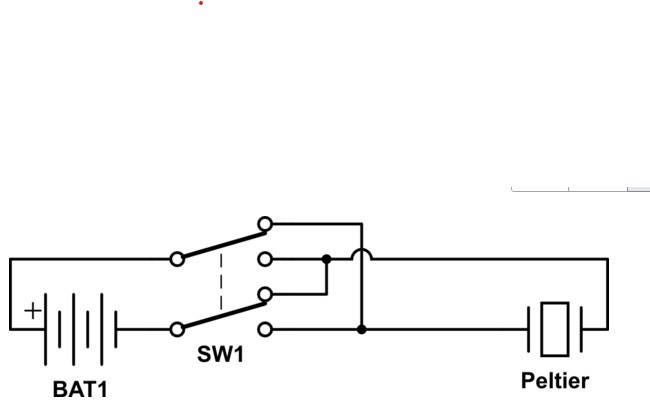

For a new design we want to use a Peltier element (+24V/70W 3.6A max) where we have to switch between cooling and heating depending on the temperature in a small climate chamber.

Therefore we use a standard LED driver module and a DPDT relay to reverse the current through the Peltier. However for the final design we do not prefer a mechanical relay but switching with MOSFETs (H bridge). So do you have a suitable device for controlling a H bridge where we can reverse the current (like a DPDT switch)? We do not have a microcontroller but we use I2C communication so we can control devices by I2C (by I/O expanders). The bridge must be able to switch at least 4A @+24V.

Best regards

Chris van der Aar

NTS- Group

Eindhoven , The Netherlands