Other Parts Discussed in Thread: DRV8308, DRV8306, DRV10970, DRV8312, DRV8308EVM

Hi,

We're using DRV10987 to drive NEMA17, 3-phase BLDC motor. Motor MPN: GM42BLF40-128-SJ-126 (gemsmotor http://gemsmotor.com/nema-17-square-brushless-dc-motor)

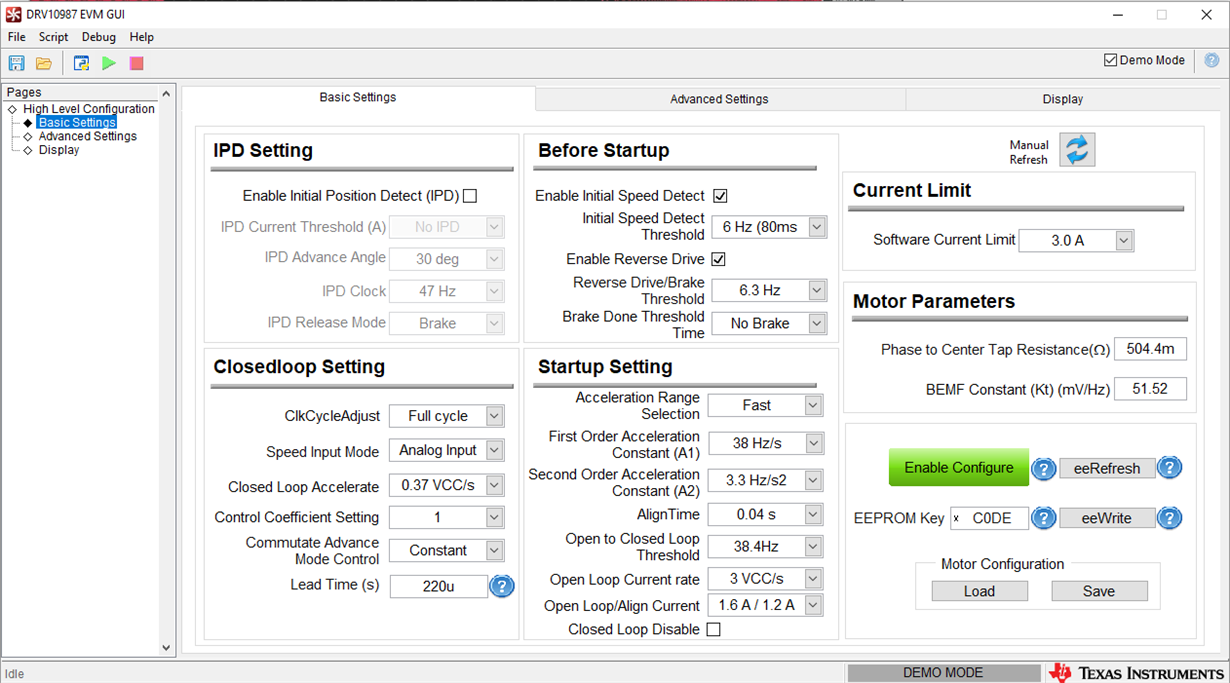

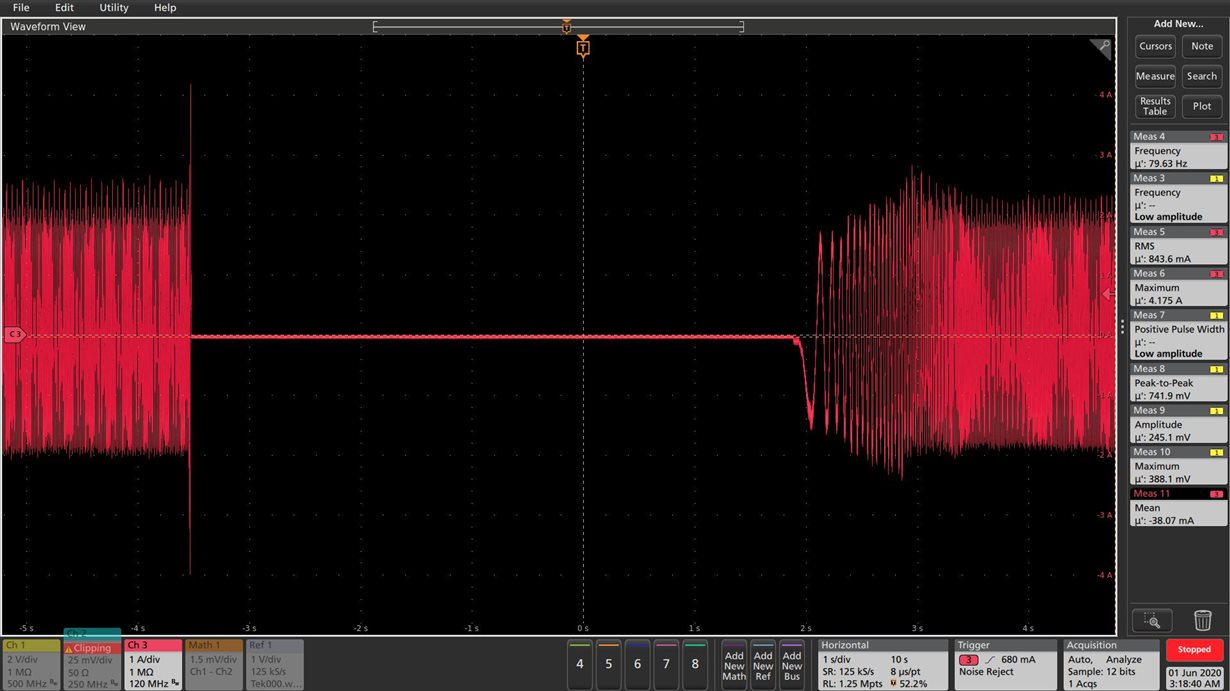

Motor enters into overcurrent protection mode (DRV10987's spec: 3.5A - 4.25A - 5.5A) while running application. This event occurs when there is need of sudden surge in required torque as motor needs to run at back pressure of -5 PSI (application case). Scope capture attached for phase current on one of phase winding and also, EEPROM configuration file attached

Questions:

- How to avoid overcurrent protection senarios?

- Is any acceleration factor is to be changed? any other EEPROM parameter is to be changed?

- Any ferrite bead will help in series with motor's UVW terminals

Operating condition:

- Peak transient current = 3.5A - 4A

- Average current: 1.5A rms

- Vcc = 12.56V

- SPEED voltage : 1.58V

- Motor speed: Approx. 90-100Hz (as per GUI)

- Phase to center Tap resistance = 504.4mOhm (1 ohm/2, Star Winding connection)

- BEMF constant, Kt = 51.55 mV/Hz

- Software current limit = 3A

- Lock detect: current limit check box = OFF, Current Limit for Lock Detection = 3.2A, lock detection control = Range2

I will send some more scope captures tomorrow -

1) VCC voltage and phase current transient rise (zoom scale)