Hello,

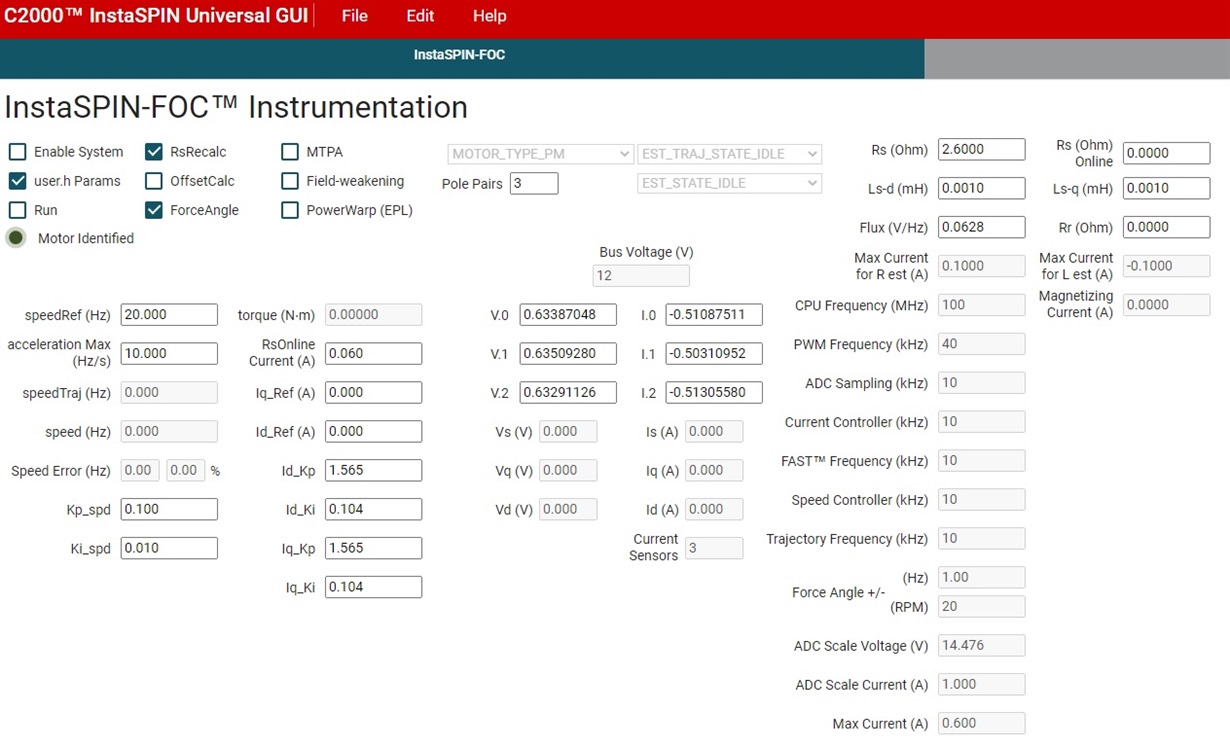

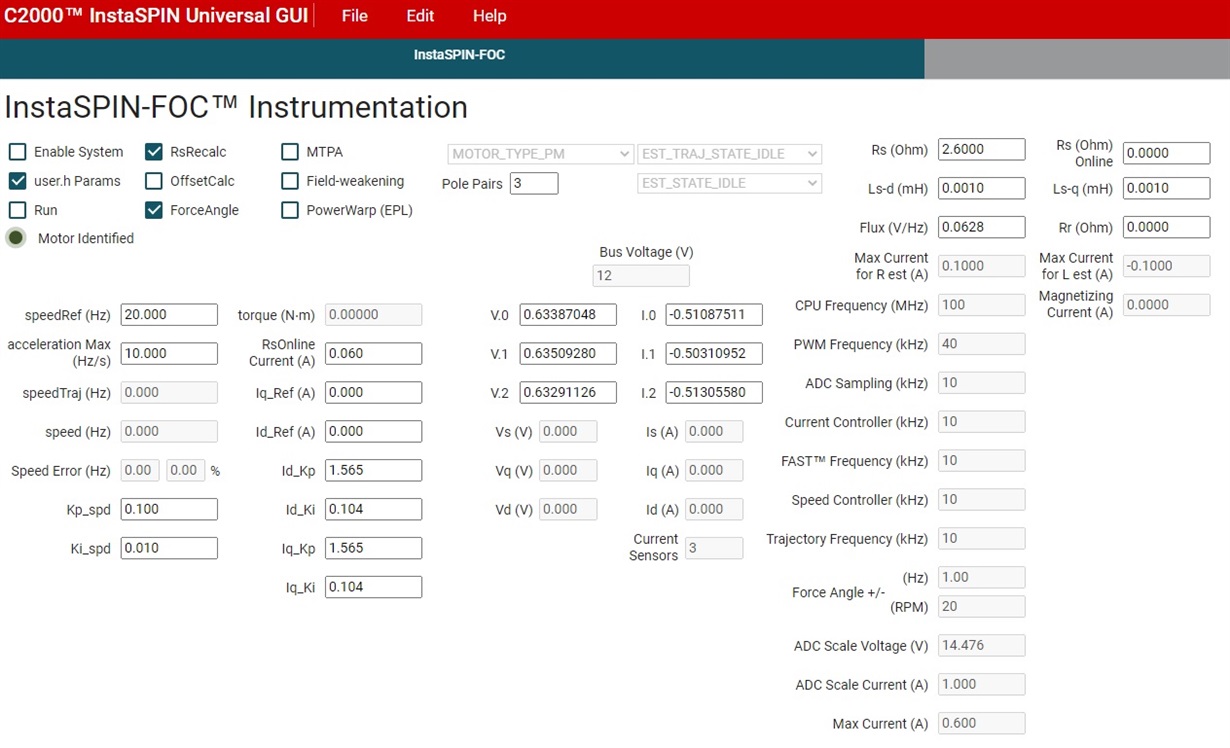

We are using the BOOSTXL-DRV8320RS and TMS320F28004x with a very small low power motor, roughly 1.8 watts. The motor voltage is 12V and draws roughly 0.15 amps @ 4000 rpm. Max motor current is 0.620 amps.

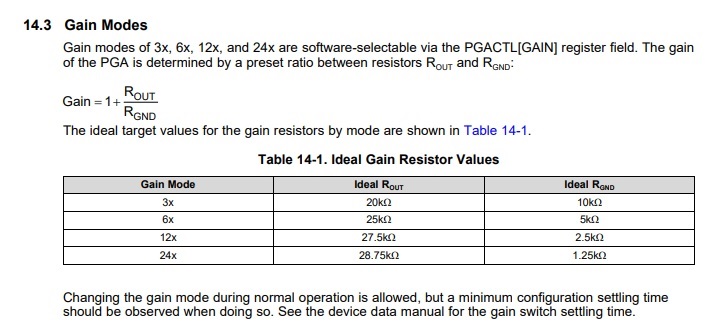

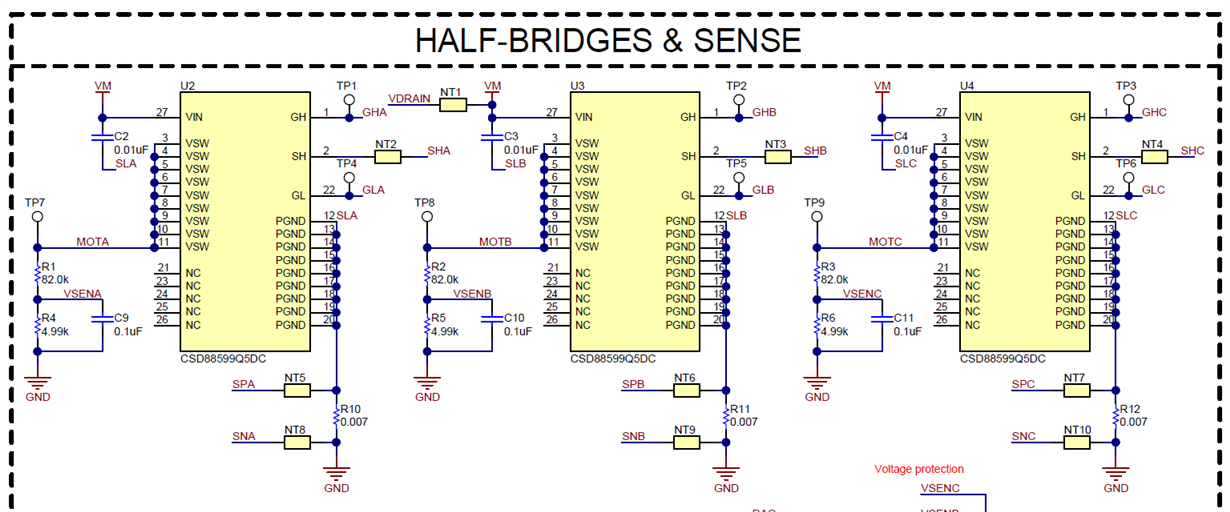

I see that we can adjust the current sense from default 12 to 24 with the PGA but with the recommended resistor values the full scale is still much to high. Are we able to user a gain/voltage diver to decrease full scale and increase resolution then adjust USER_ADC_FULL_SCALE_CURRENT_A from user.h? What is a good rule of thumb for head room? Should we also adjust the cap values? Is there an advantage of using one gain over another?

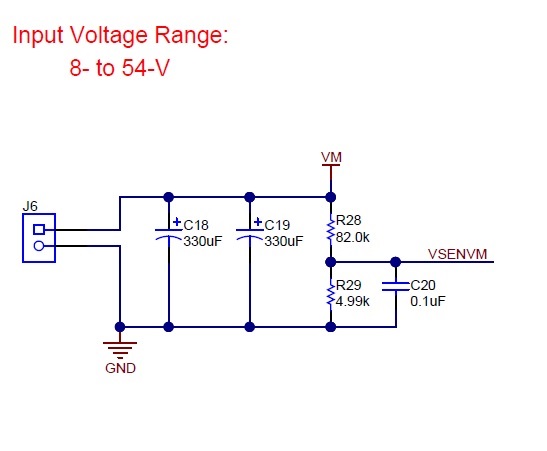

We also have the same question for the voltage sense? If we adjust the voltage divider, R1/R4, R2/R5, and R3/R6 do we only need to adjust USER_ADC_FULL_SCALE_VOLTAGE_V in user.h? How much heaqd room should we allow? Should we also adjust the cap values?

I assume we do the same for VM with R28/R29 as the others above?

Thanks in advance!