Hi Team,

We would like to seek support if there is a minimum or ideal pulse width for this device when using it on PWM?

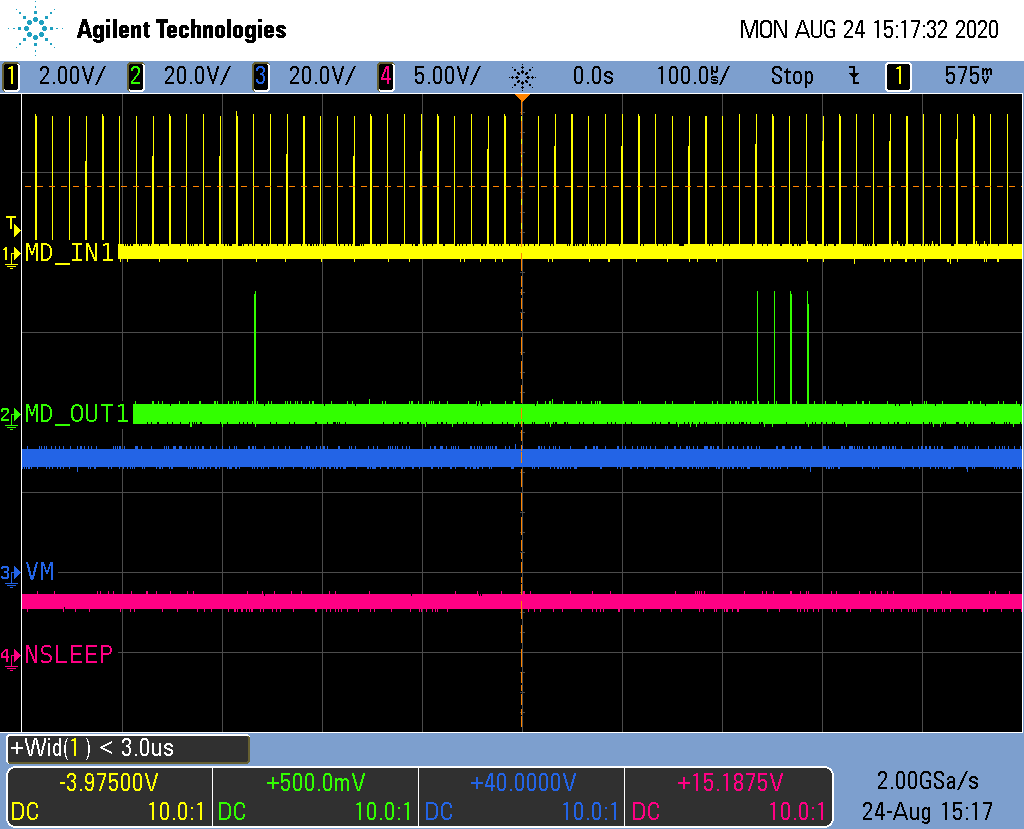

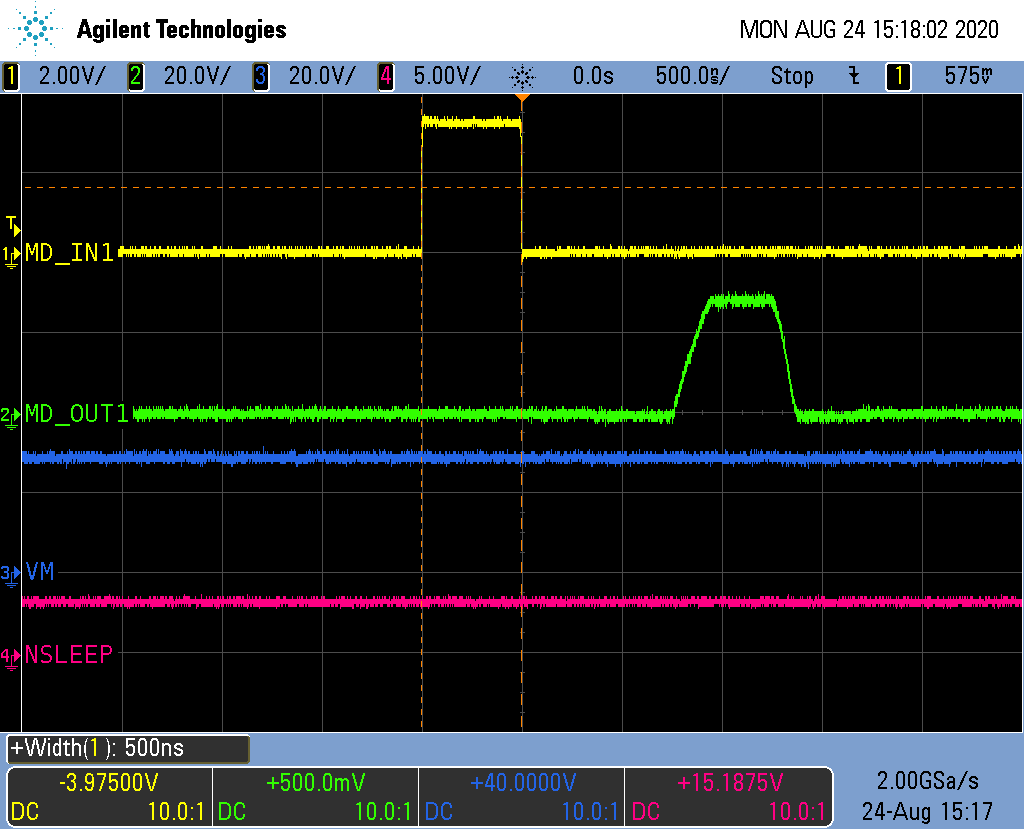

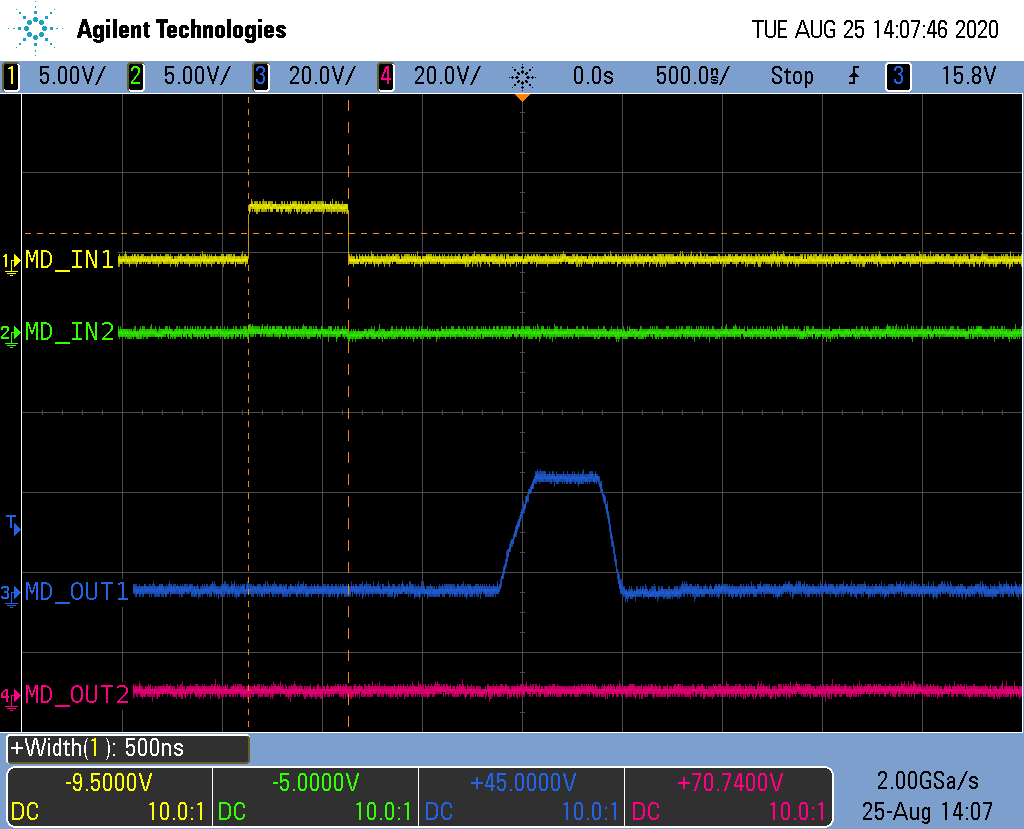

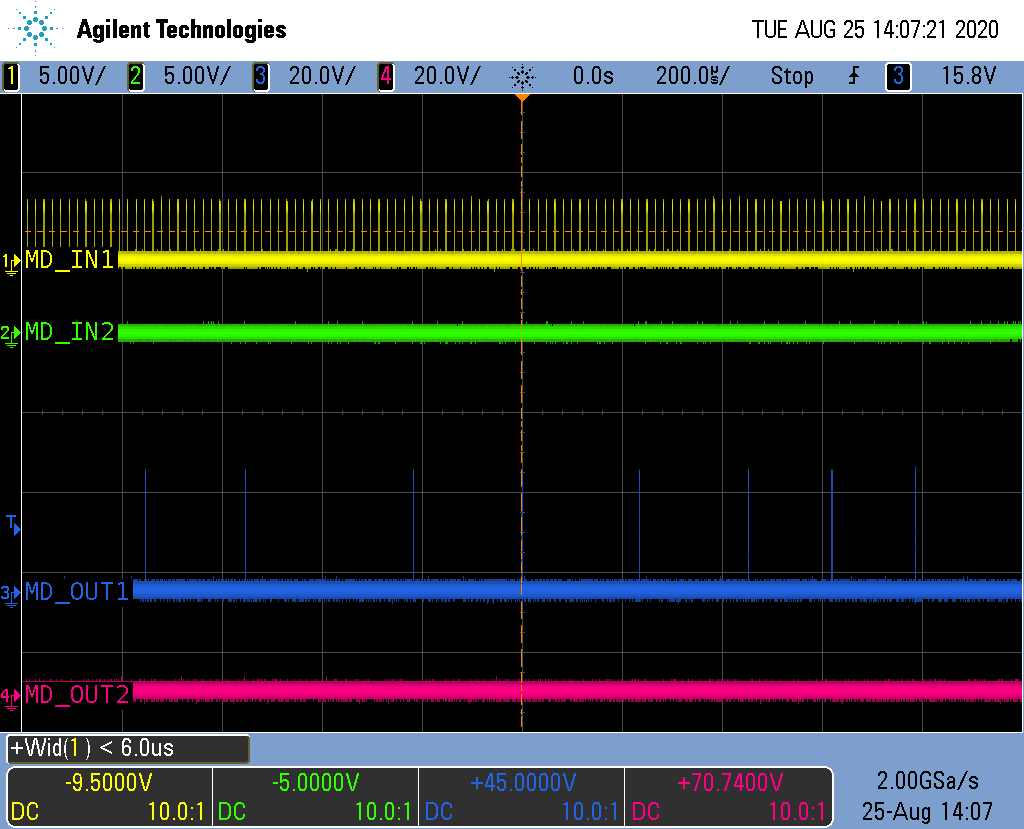

Observation on different conditions.

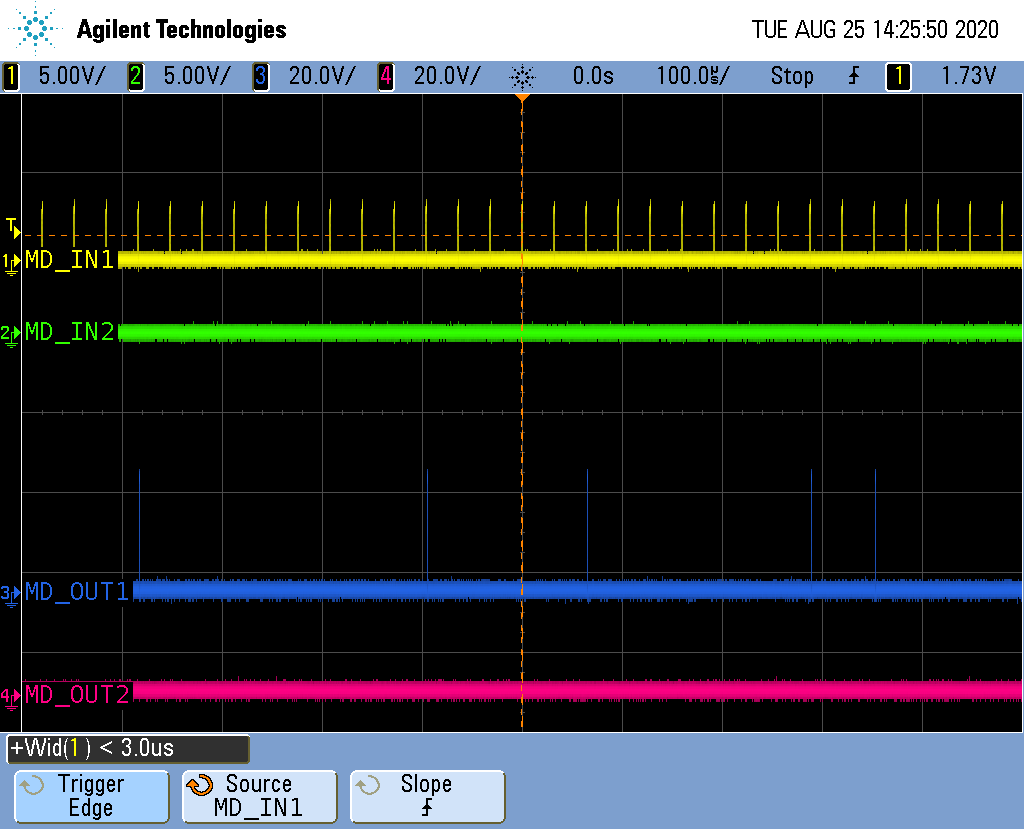

when motor driver (MD) provides pulses to motor every period, is 800ns

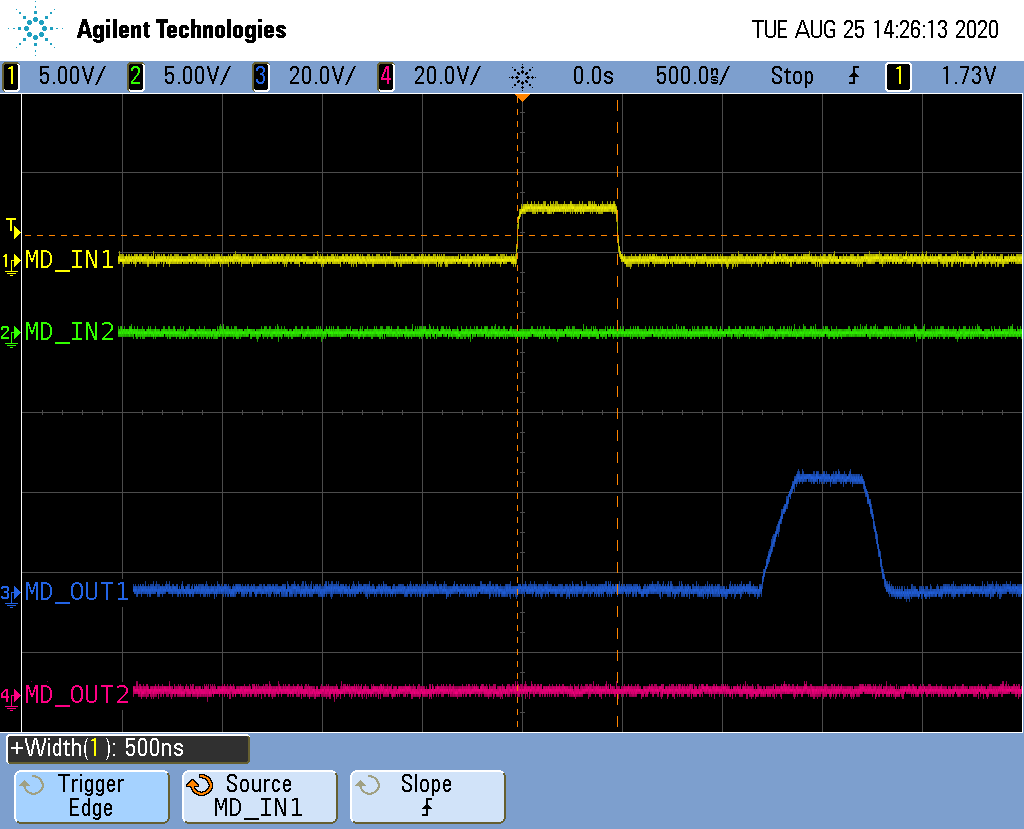

when MD provides pulse to motor but not for every period is 490ns

Thank you in advance.

Regards,

Mark Felipe