Hello,

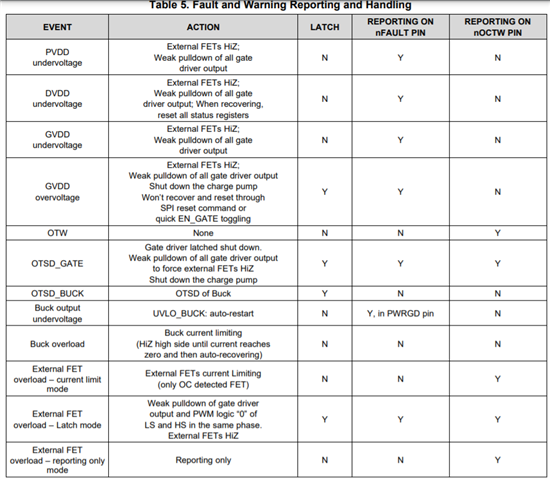

I am trying to build a BLDC motor controller with the DRV8302, and have generally followed the typical application schematic on page 21 of the datasheet (aside from some mode settings). My motor runs at 24V, but even when I power the driver between 8-10V, with a 5V reference, I experience a fault on the nFAULT pin. While the nOCTW stays high, I noticed that the chip feels hot. Furthermore, my supply tells me that the chip is drawing 0.16A, but the typical rating seems to be 0.015A. I am unsure if this is because there is a load connected on the gate drive output, or if this is related to the fault. I have also checked all the VDD's to verify their values.

Are there any pointers as to what the issue may be?

I have attached my schematic below.

Thank you!

Robby