Background

I have the DRV8889 soldered to a PCB and connected to an ATmega4809 mcu.

The circuit is a copy of the "recommended circuit" from the datasheet. Motor is running @24 V.

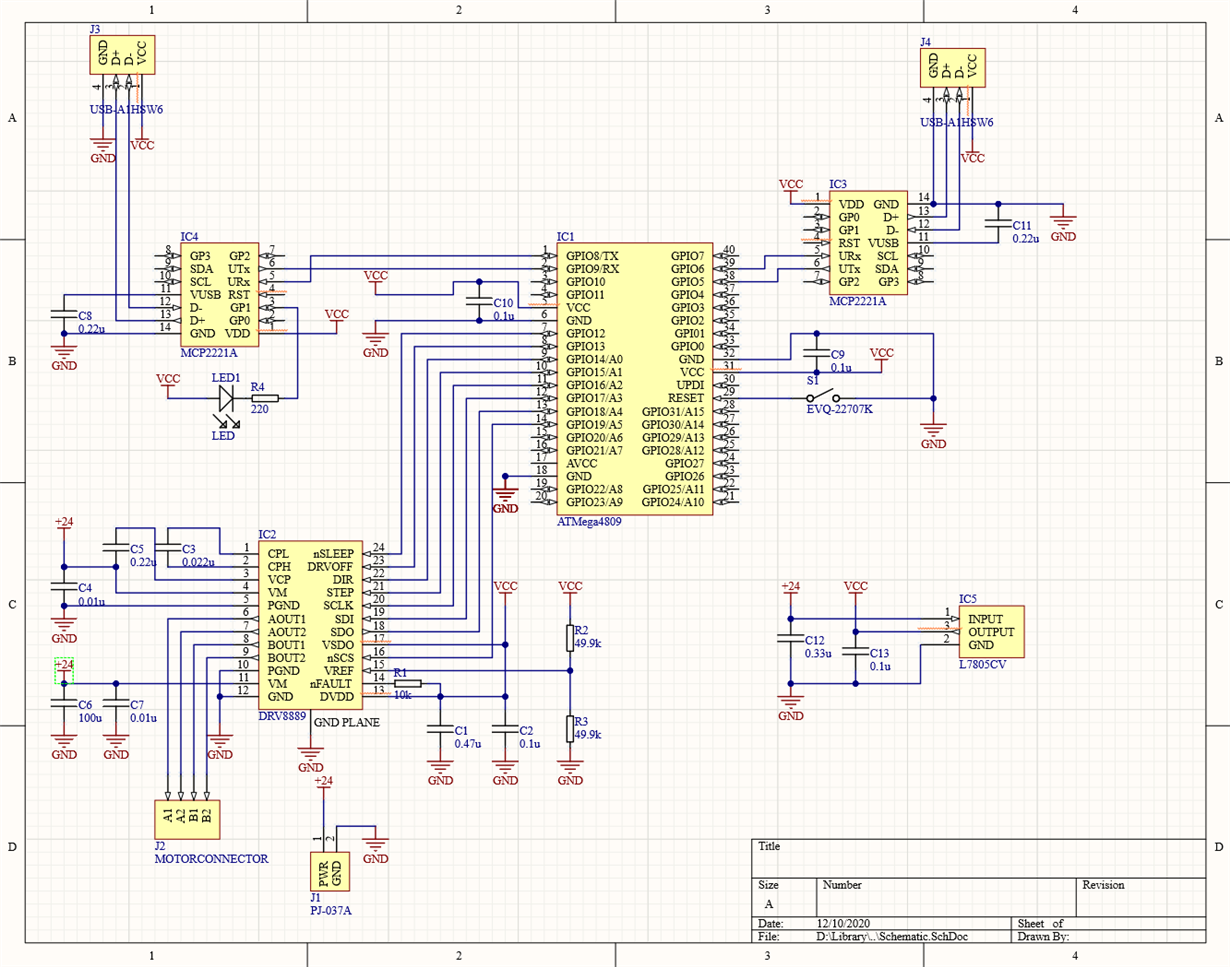

Here is my schematic of the connections between the driver and my mcu.

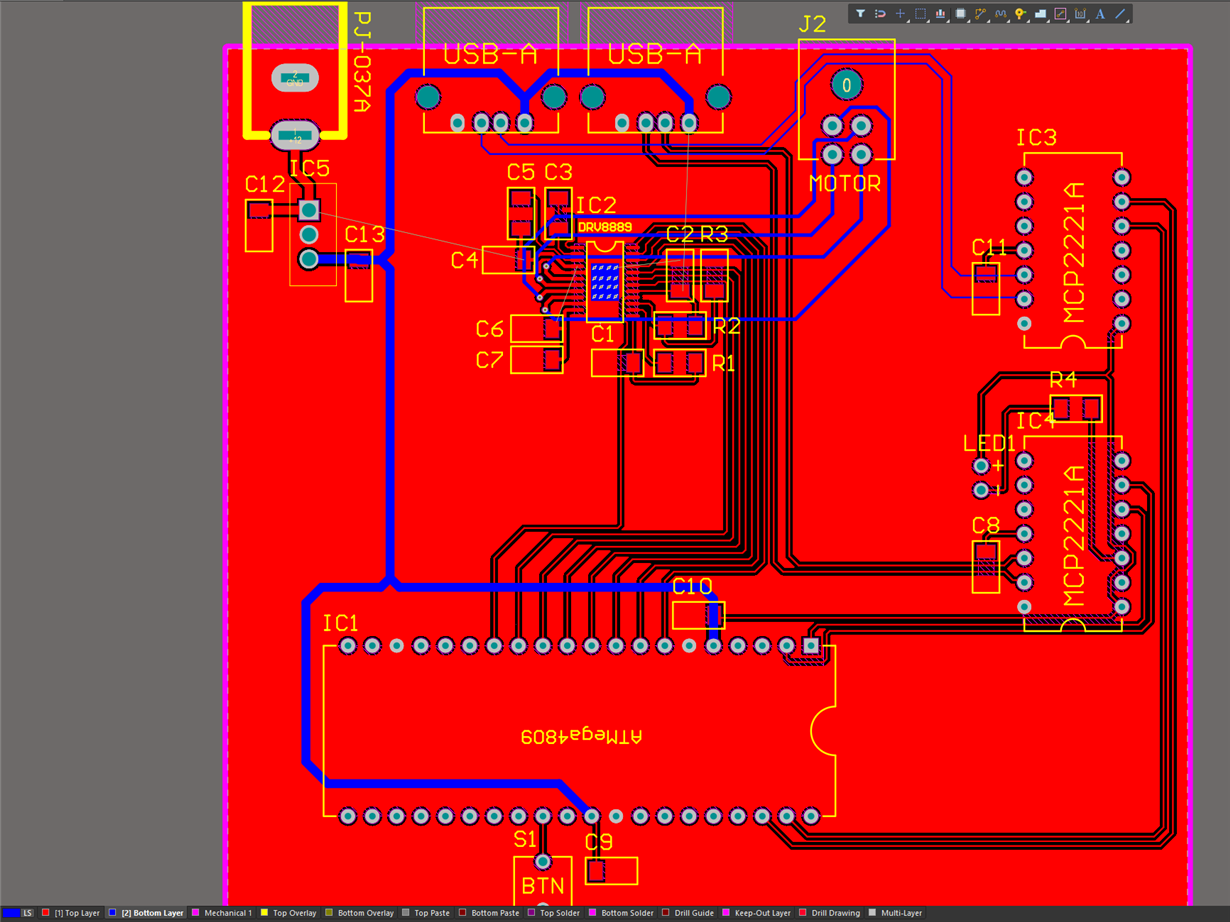

Due to a Git error, I have lost the most recent version of my PCB. This version is very similar with the exception of some traces still unrouted. I'll still include a screenshot in case someone finds it usefull.

Link to my motor: www.digikey.ca/.../11564434

The motor does not overheat.

Behavior

Ctrl register one = 00110000 (Trq = 81.25%, everything else default)

Ctrl register two = 00001111 (DIS_OUT = 0, everything else default)

All other registers are normal.

Motor turns on and works as expected. After about 10 seconds of operation, the overtemp warning is triggered. After about 15 seconds the overtemp fault is triggered. At this point, the DRV is extremely hot to the touch (to the point where it is painful to touch).

I have attached a small copper heatsink to the chip which helps a bit, but it eventually overheats the same way.

When it is not overheating, it works find.

Soldering

I soldered this by hand with an iron. It seems to have worked fine but I'm wondering if I somehow damaged it by heating it for too long?

Thanks in advanced for any help or suggestions.

Best Regards,

Brian