Other Parts Discussed in Thread: DRV8300, DRV8301

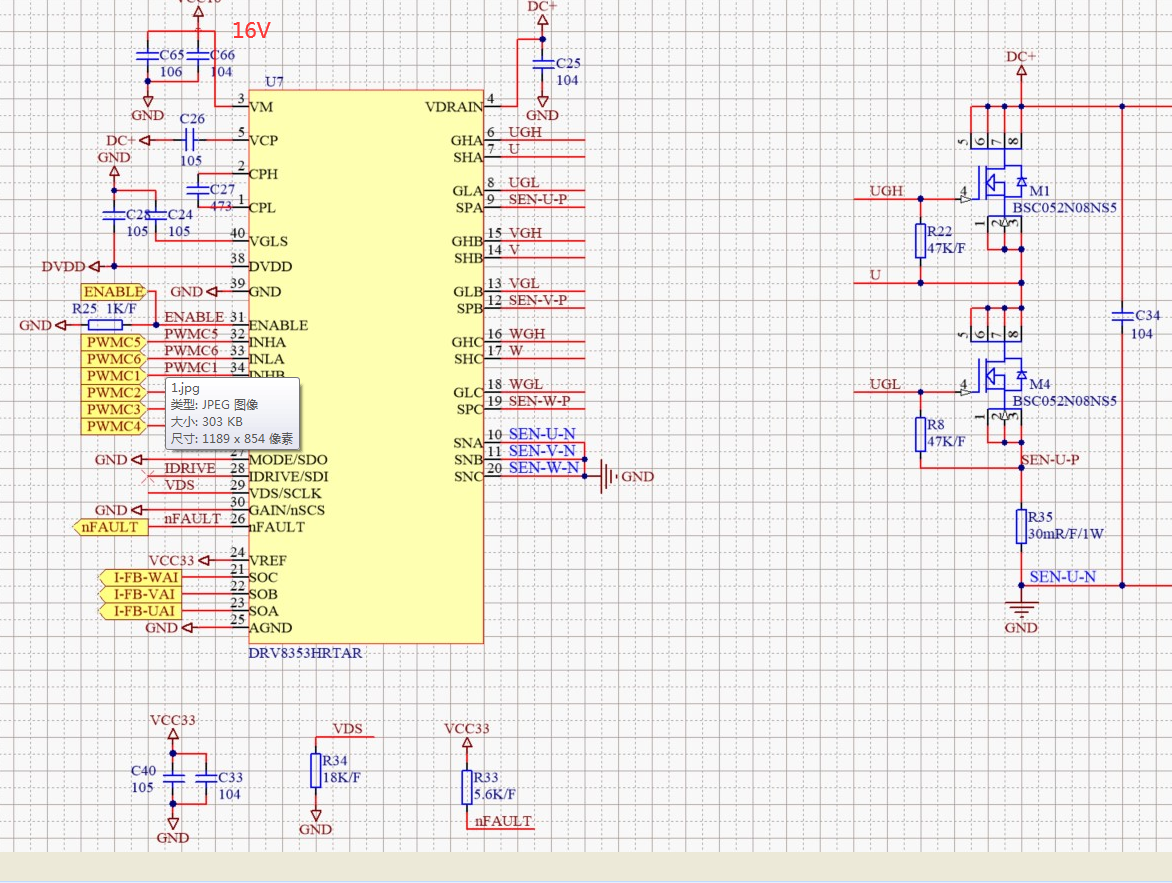

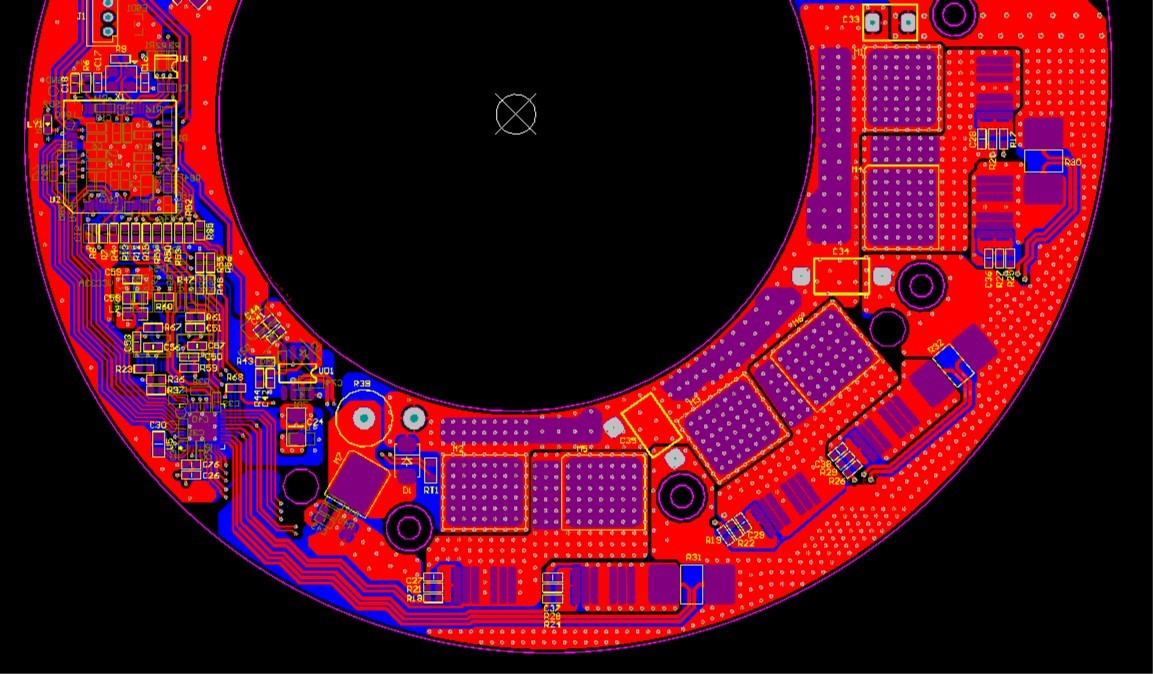

The Schematic and PCB is as follows:

-

When the motor wire short circuit test,the device is damaged.There are two types of damage:

- 1.High voltage side drive voltage C26 and Low voltage side drive voltage C24 are basically 0 volts.VDVDD is 5V.And the DRV8353H 's temperature reaches 150℃,the device is damaged.

- 2.High voltage side drive voltage C26 and Low voltage side drive voltage C24 are basically 10 volts,VDVDD is 5V.but the device No response to input PWM.

- so,What may have been the cause of the damage? I had damaged many device.

- Thank you !