Other Parts Discussed in Thread: BQ76952

Hi Matt,

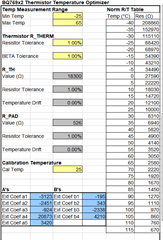

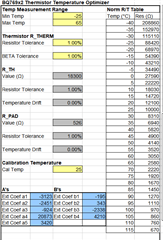

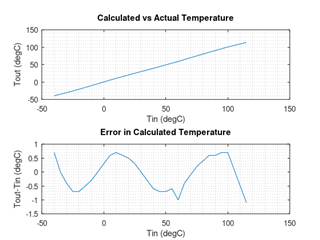

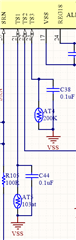

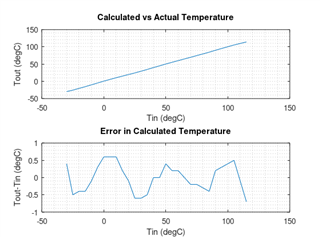

For the temperature measurement, I use a 10K NTC, and B = 3435, the same as Semitec 103-AT thermistor which is suggested in the paper "Improving temperature measurement accuracy in battery monitoring systems". But I found the temperature value I read out from the Reg is very inaccurate. In room temperature, I got near 30 degrees centigrade. But with real temperature 34 degrees, the error goes low. I got 37 degrees.

How should I set to make the measurement more accurate? Seems only set the offset, it doesn't works.

Thank you, and looking forword for your feedback.