Other Parts Discussed in Thread: TPS63810, TPS63811, SN74LVC3G07

Hi guys,

TL;DR: I did all the math that seems to work out fine, but I can't get above 3.7v output. My target is up to 6.0v output.

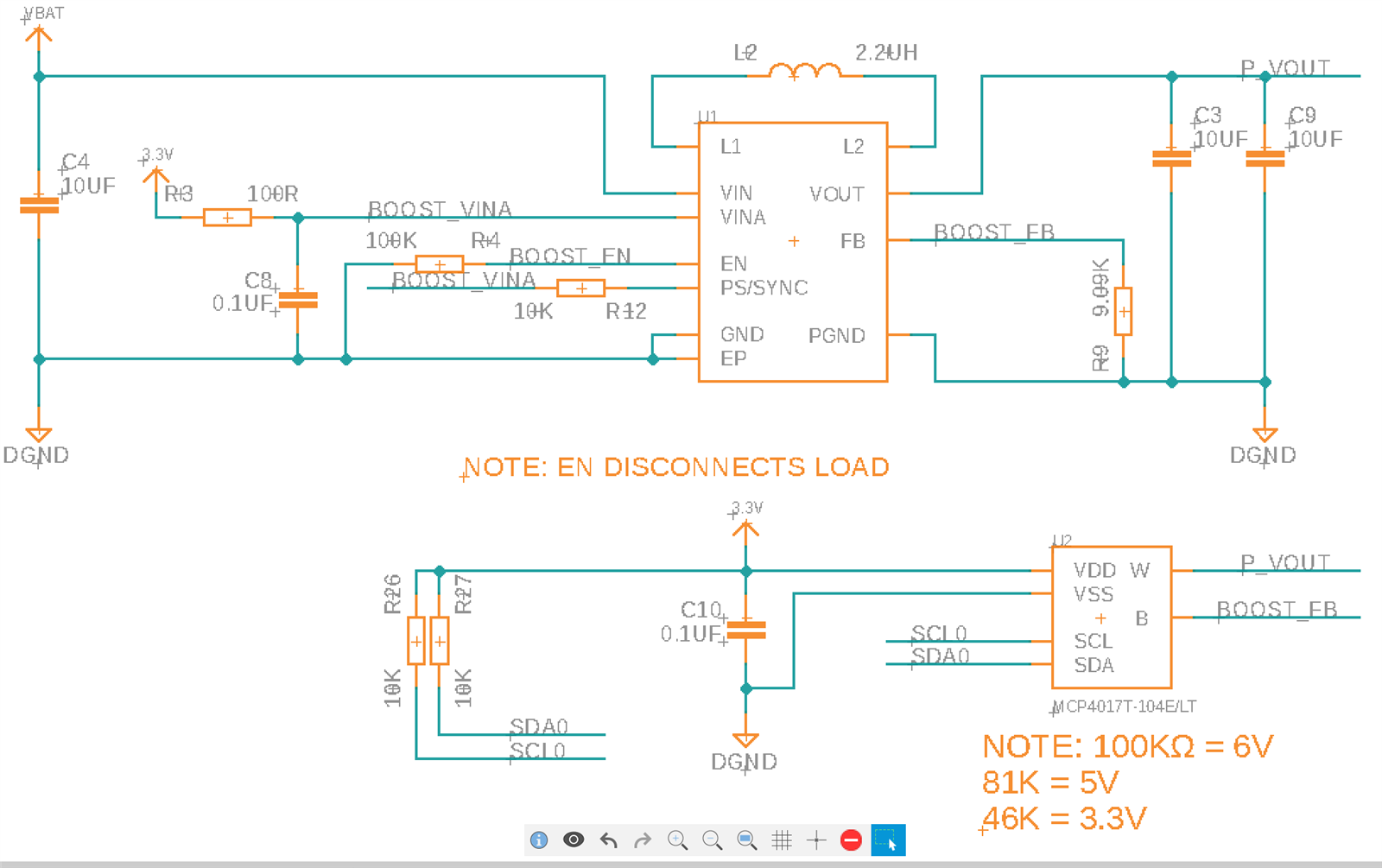

Here's my schematic:

I'm using a digipot in rheostat mode to adjust R1 between 0Ω and 100KΩ. The adjustments work as expected up to ~3.7v when I feed VBAT with 3.2v. It never goes above that however. BOOST_EN is driven by a GPIO at 3.3v elsewhere.

Per the datasheet calculus, this arrangement should provide a boost of up to 6.0v. The inductor I'm using is the Samsung CIGT201610LH2R2MNE (https://www.digikey.com/short/0r02hhb3): 2.2UH, 1.8A, 139mΩ which should satisfy the requirements. I added a 500Ω load and got the same results.

Can you help me understand why this isn't boosting above 3.7v?