Hello everyone

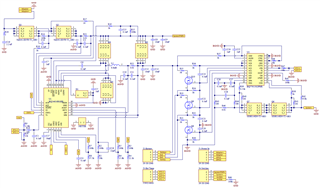

I have recently designed a charge controlled for a 3-cell Lithium-Ion battery using the BQ24616. Apon testing the board, I noticed that the current that the battery charges at is much lower than it was designed. The charge controlled was designed to for a fast charge current of 4.5A but I am only getting 1.35 A. Below are the full design parameters:

Vin = 24 V

Vbat = 12.6 V

Iadp = 3 A

Iprechg = 0.45 A

Ichg = 4.5 A

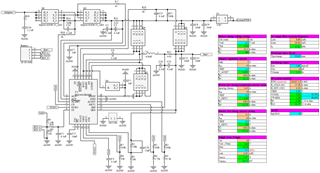

And here is my schematic as well as screenshots of the design calculations, from the tool provided by TI:

The test was conducted using a laboratory power supply, set at 24V and 6 A, as the power source. All the FETs that control the power switchover are working and the battery does start to charge when the power supply input is applied. the charge current is just too low.

I tested two different batteries, one from low state of charge and from from a medium state of charge, with the same results. I charged both batteries with the lower charge current of 1.35 A until the charger stopped charging. This stop occurred at 12.45 V, rather than 12.6 V as per the design. The controller is supposed to end with a constant voltage phase and then terminate with a low current (0.45 A as per design), yet I did not observe a constant voltage phase and charging was terminated with 1.35A still flowing.

Here are the snapshot values of all the parameters that I could measure during charging:

Supply current: 0.7 A

Supply voltage: 24 V

Charge current: 1.35 A (design value: 4.5 A)

Charge voltage: 11.1 V

Fb pin voltage: 1.893 V (measured over R1)

Iset1 pin voltage: 0.95 V (measured over R8) (design value 0.9 V)

Iset2 pin voltage: 0.631 V (measured over R6) (design value 0.45V)

ACset pin voltage: 0.660 V (measured over R4) (design value 0.6 V)

TS pin voltage pin: 2.11 V (thus within temperature range)

REGN pin voltage: 5.938 V

Vref pin voltage: 3.271 V

There was one other thing I noticed while taking the measurements that could be relevant: When I was measuring the Iset1 voltage over R8 (the one responsible for programming the current limitation), the charge current jumped to 2.15 A. As I stopped measuring (removed the probe) the charging current went to 0 A for a second and then resumed at 1.35 A like normal.

I would greatly appreciate it if anyone can help me to understand this strange behaviour or point out a possible mistake in my design. Thanks in advance.