I have mad an eval board for some tests on replacing an existing PMIC on one of our mainboards.

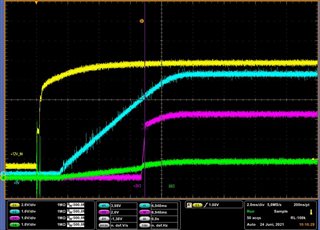

The BUCK1 controller won't start properly to regulate to 5V, just 0.3V are on the output.

After controlling the complete circuitry i found out the FET driving signals seem to be very sensitive.

So when playing around on GL1 with measure tips sometimes the channel gets working.

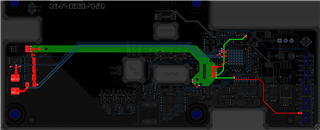

Since this channel has an offset FET with some distance of about near 100mm i wonder if there are other special recommendations on the routing?!

I guarded signal lines within an inner layer between grounds and avoided noise where possible.

Are there measures to improve drive strength or something similar?

What workarounds could be tried before putting the PCB to re-design?

Thx for the help in advance!