Hello TI team,

I'm working on a low power application using a TPS61021A.

To save power I turn on/off the TPS61021A often.

The device is battery powered (AAx2) and if the batteries are below around 40% charge, the voltage drop caused by the TPS61021A startup current is a problem.

I've lowered the output capacitor and increased the input capacitor but it's not enough.

To further limit the startup current I'm considering two ways :

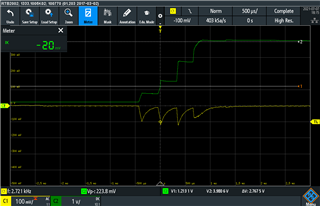

1. Enabling the TPS61021A gradually

I pull the EN pin high for around 80us then low then high again until reaching the nominal output (4V).

This method seems to be working well.

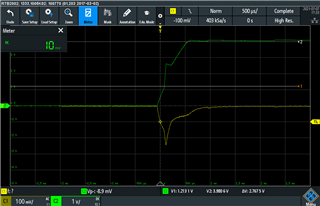

On the graph below green is TPS61021A output and yellow the voltage drop on the battery. Voltage drop is limited to around 100mV compared to around 350mV with a regular startup.

Is this method reliable enough for high volume production ?

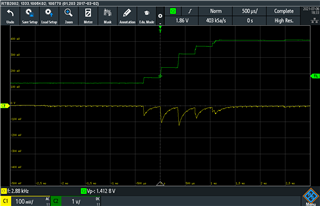

2. Using a RC circuit on Fb pin

The method is described here : https://www.ti.com/lit/an/slva307b/slva307b.pdf

I tried it but the results are not as good as the first method. It seems that the first startup phase (output capacitor charging) is not impacted.

Does the note slva307b applies to TPS61021A ?

Thanks for your help

Guillaume