Hello,

We have an 802.3at PD design by using LM5072-80. The design is a flyback design with output of 12V/2A.

It is working well with small output ripple (< 60mV) in static load. However, the output ripple is large than

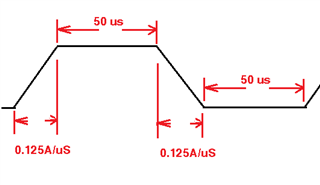

1V when the PD is loaded with an Electronic Loader which was setting with fast transient (125mA/us).

The PD has been equipped with a "LC low pass filter" at output port.

Is there any way to reduce the output ripple for dynamic load? Is this large ripple related to poor bandwidth,

or it is unstable at fast load transient? Should I fine tune voltage compensation loop?

Best Regards,

David