Other Parts Discussed in Thread: TPS92633-Q1, TPS92633

Good day, Hope you are all fine.

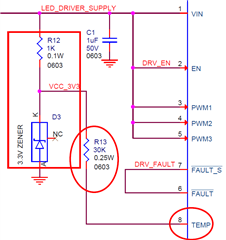

One of our design, We are using TPS92630-Q1 three channel LED driver. We plan to introduce 5 LEDs like OUT1 - 2 LEDs, OUT2 - 2 LEDs and OUT3 - 1 LED. Kindly let me know whether 1 LED per channel (OUT3) combination is fine.

VIN = 9 - 18V

LED forward current = 130mA

LED part number = NFSW172

PWM = 100%

Thanks and regards,

Kanthavel Kumaran

Technical Lead

Hardware design and development

Capgemini