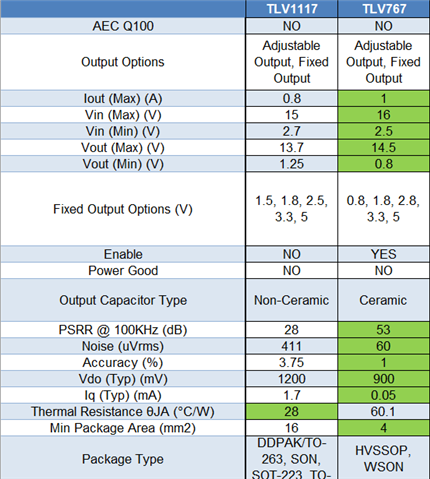

This question isn't necessarily about a TI part, but you do sell regulators that I'm interested in. My problem has to do with using these imported isolated 1 watt DC-DC power converters. I did a design that uses one single output and one dual output, the trouble is with the dual which is 5 volt input +/-12V output. I was feeding the input with a part like TLV1117 so overvoltage wasn't possible, but its input was fed with a wall wart whose output was "erratic" and the dual converters kept blowing up even without a load. So the only "problem" could have been operating with undervoltage. Now I have three different vendors for these parts, but in truth they could all be coming off the same production line in China, and the product support for these parts is nonexistent. I can look at any of these "data sheets: (really they're just product matrices) and there is zero indication that "undervoltage lockout" is needed. And interestingly the single didn't have a problem with any of this! Now I know you have some parts (TPS7A92 comes to mind, that one's probably overkill for the job) that are linear regulators with UVLO, but I just wanted to know if you think "burying" a design requirement for the supply by deliberately not publishing it is now "par for the course", or if anyone here has any experience with these little time bombs?

-

Ask a related question

What is a related question?A related question is a question created from another question. When the related question is created, it will be automatically linked to the original question.