Hi,

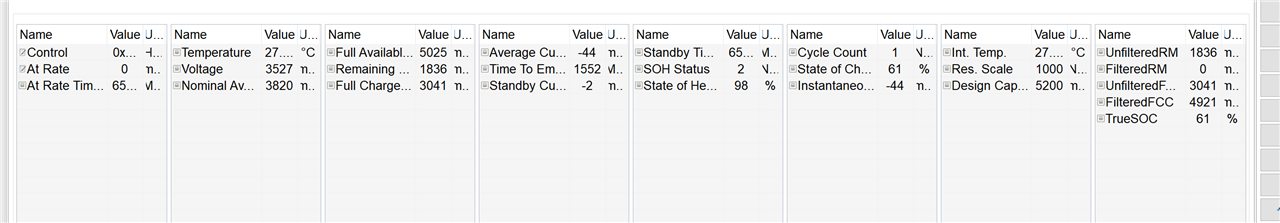

I have performed what I thought was a successful learning cycle on my 1S2P 18650 battery pack but the fuel gauge provides inconsistent results especially when seeing higher loads. A few things I have observed:

1. Starting from a fully charged battery, the fuel gauge shows what appears to be a normal discharge curve until it hits about ~50%. Then it drops right to 0%. Battery voltage is still around 3.7V OCV.

2. Another example. When charging the battery the capacity is reported to be 30%. If I stop charging the capacity will drop to 0%.

3. Reported Capacity looks normal when charging.

I have attached my logs from my learning cycle for review. Appreciate any help

Thanks

Eric